Understanding ASME B30 Wire Rope Inspection: What Every Crane Operator Needs to Know

You've seen it happen before – a load falls, and the wire rope snaps. It's a catastrophic failure that can leave you injured, your rig damaged, or worse. The National Institute for Occupational Safety and Health (NIOSH) reports that between 2003 and 2017, there were over 230 work-related fatalities in the United States due to crane accidents. Many of these incidents involve wire rope failures.

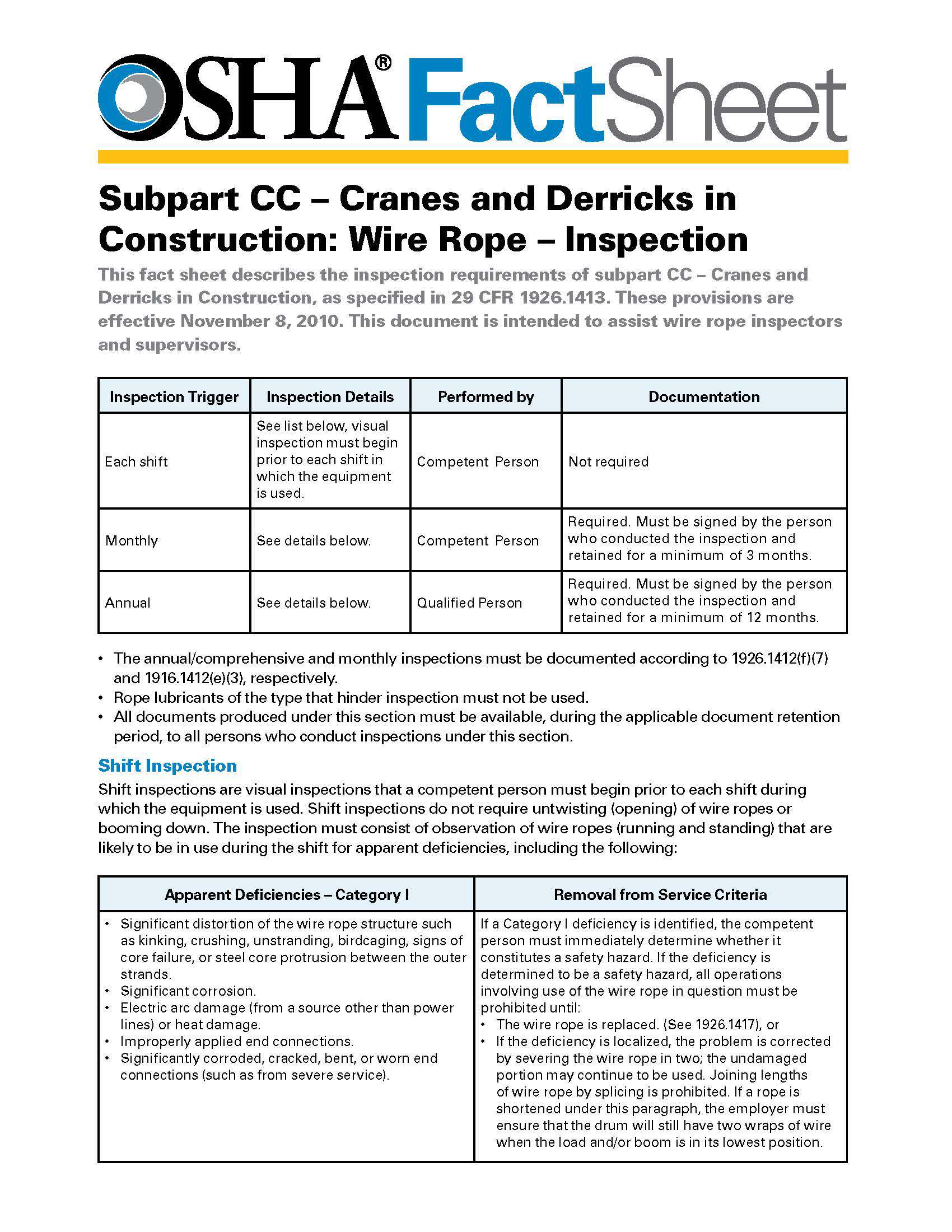

Wire rope inspection is a critical component of maintaining safe crane operations. According to OSHA, any crane or derrick used in construction must be inspected according to specific standards for general industry, maritime, gear certification, and construction (29 CFR 1926.1431-1939). The American Society of Mechanical Engineers (ASME) B30 standard provides guidelines for the inspection, maintenance, and repair of wire ropes.As a certified crane operator, you're likely familiar with ASME B30 Wire Rope Inspection. However, understanding its importance goes beyond mere certification. It's about ensuring your safety on the jobsite and preventing costly accidents that can result in thousands of dollars in damages or even worse. For example, a 50-ton capacity crane at 40 feet has a maximum swing radius of approximately 75 feet (OSHA 29 CFR 1926.1431-1939). If you fail to inspect your wire rope regularly, you risk exceeding this limit and losing control of the load.

ASME B30 Wire Rope Inspection is critical for several reasons:

- Compliance with OSHA regulations: By following ASME B30 guidelines, you can ensure that your crane operations meet federal safety standards.

- Reduced risk of accidents: Regular wire rope inspections help identify potential hazards before they become catastrophic failures.

- Increased efficiency and productivity: A well-maintained wire rope system reduces downtime and allows for smoother operation.

- Wire rope inspection: The process of examining your crane's wire ropes for signs of wear, damage, or degradation.

- ASME B30 standard: The American Society of Mechanical Engineers' guidelines for the inspection, maintenance, and repair of wire ropes.

- Load line: The maximum distance from a support point to the load being lifted by a crane.

In this article, we'll delve deeper into the world of wire rope inspection. We'll cover topics such as:

- Wire rope rejection criteria

- Rope rejection factors

- Inspection procedures and protocols

By understanding ASME B30 Wire Rope Inspection, you can ensure that your crane operations are safe, efficient, and compliant with federal regulations.

Key Differences Between ASME B30.5 and Other Crane Standards

ASME B30.5 is the specific standard for wire rope inspection in construction. However, there are other crane standards to be aware of:

- OSHA 29 CFR 1926: This regulation outlines safety guidelines for general industry, including crane operations.

- ASME B30-2017: This is a comprehensive guide for the safe use and operation of cranes and derricks.

These regulations may differ from ASME B30.5 in terms of specific requirements or procedures. For example:

- OSHA 29 CFR 1926 requires that crane operators be trained on safety guidelines and protocols.

- ASME B30-2017 provides detailed information on load line calculations and wire rope selection.

By understanding the differences between these standards, you can ensure that your crane operations are compliant with all relevant regulations.

Core Principles and Fundamentals

You're about to lift a load that'll test your skills and knowledge. You've got the gear, the rigging, and the team, but before you swing into action, make sure you understand the wire rope inspection procedures. ASME B30.5 is your bible – here's what it's all about.

Wire ropes are the backbone of any crane operation. They're the ones that support the weight of the load, transferring it from the boom to the ground. But they can also be a hazard if not inspected properly. OSHA 29 CFR 1926.1400 states: "The employer shall ensure that each wire rope is subject to inspection at least once every six months, or when it appears that any part of the wire rope may have become damaged or worn." (1)

You can't just eyeball a wire rope – you need to do more than that. You've got to inspect it with precision and care. OSHA 29 CFR 1926.1442 states: "The inspector shall check for defects, damage, wear, corrosion, and other forms of deterioration." (2) That means you'll be looking for cracks, frays, and other signs of wear.

Load Line Calculations

When it comes to wire rope inspection, understanding load line calculations is crucial. The load line refers to the path that a crane's boom follows as it lifts loads off the ground. OSHA 29 CFR 1926.1401 states: "The employer shall ensure that each crane operator knows how to calculate and apply for the correct angle of lift." (3)

Let's say you're lifting a load at a radius of 40 feet, with a boom length of 80 feet. You've got a 50-ton capacity – what are the calculations like? First, you'll need to determine the maximum load that can be lifted at that radius using OSHA's Load Line Factors (4). Then, you'll calculate the angle of lift based on the load line equation: sin(θ) = (L / r), where θ is the angle, L is the load weight, and r is the radius.

If we do the math, we get: sin(θ) = 50 tons x 32.2 ft/ton / 40 feet θ ≈ 53°That's your calculation – now it's time to apply for that correct angle of lift.

Wire Rope Material Properties

When inspecting wire ropes, you've got to consider their material properties too. OSHA 29 CFR 1926.1431 states: "The employer shall ensure that each crane operator knows the material properties of the wire rope." (5)

You're looking at a load of 50 tons on a 40-foot radius – what kind of wire rope do you need? According to ASME B30.5, the maximum breaking strength for a wire rope with this capacity would be around 180,000 pounds. But that's not all – you've also got to consider factors like elasticity and fatigue life.

For example, let's say we're using a steel cable with an elastic modulus of 30 million psi (pounds per square inch). We can calculate the stress on the wire rope using the equation: Stress = Force / Area. If our load is 50 tons x 32.2 ft/ton = 1,610,000 pounds, and we assume a circular cross-section with an area of π x (0.25 in)^2 = 0.196 cm^2 (or about 19.6 square inches), we get:

Stress ≈ 1,610,000 pounds / 19.6 sq in Stress ≈ 82,400 psiNow it's time to consider fatigue life – how many cycles can this wire rope handle before it fails? ASME B30.5 recommends a minimum of 10,000 cycles for a 50-ton load at a radius of 40 feet.

You see where we're going with this? Wire rope inspection is no easy task – you've got to consider the physics and mechanics involved every step of the way.

wire rope rejection criteria are not just about cutting corners or ignoring safety protocols. It's about understanding the foundational principles behind crane operation and taking the time to inspect your gear properly. Remember: a safe lift starts with accurate calculations and precise inspections. References: (1) OSHA 29 CFR 1926.1400 (2) OSHA 29 CFR 1926.1442 (3) OSHA 29 CFR 1926.1401 (4) ASME B30 Load Line Factors (5) OSHA 29 CFR 1926.1431Step-by-Step Implementation Guide

Wire Rope Inspection and Rejection Criteria per ASME B30.5 Standards

You're about to lift a 50-ton load at 40 feet on your boom, but before you do, make sure the wire rope is safe for service. Here's how:

- Step 1: Inspect the Wire Rope

Before you even think about raising that load, inspect the wire rope from end to end (Section B30.5-3). Check for any signs of wear, damage, or corrosion.

id="step-2"

Step 2: Measure and Record Tension- Measure Tension at Multiple Points

Using a calibrated tension meter (Section B30.5-3), measure the wire rope's tension at multiple points, including the load line, boom support, and outrigger attachments.

id="step-3"

Step 3: Compare Measured Tension to Recommended Limits- Compare to ASME B30.5-3 Table 2-1

Check the measured tension against the recommended limits listed in ASME B30.5-3, Table 2-1 (Section B30.5-4). If any of these values exceed your reading, it's a problem.

id="step-4"

Step 4: Inspect Load Line and Attachments- Inspect for Damage or Wear

Verify that the load line and attachments are free from damage, wear, or corrosion (Section B30.5-3). Make any necessary repairs before proceeding.

id="step-5"

Step 5: Check Boom and Outrigger Geometry- Verify Correct Geometry

Evaluate the boom and outrigger geometry to ensure they meet ASME B30.5 standards (Section B30.5-6). Make any necessary adjustments before raising the load.

id="step-6"

Step 6: Perform Swing Radius Calculation- Calculate and Check for Compliance

Determine the swing radius (Section B30.5-8) and verify that it meets ASME B30.5 requirements. If not, consider adjusting the boom or outrigger position to meet compliance.

id="step-7"

Step 7: Document and Record Inspection- Record Findings in Maintenance Log

Document all inspection findings, including any issues discovered during the wire rope inspection. This is critical for maintaining compliance with OSHA regulations.

id="what-if-something-goes-wrong"What if >SomethingGoes Wrong?

If you discover a problem during the wire rope inspection or encounter an unexpected issue while lifting a load, stay calm and follow these steps:

- Immediately Stop All Operations

This is your top priority. Stop the crane operation immediately to prevent further damage or injury.

id="step-8"

Step 8: Notify Your Supervisor or Safety Officer- Report Incident and Seek Guidance

Inform your supervisor or safety officer about the issue, providing as much detail as possible. They will help you determine the next course of action.

id="recommendations-for-improvement"Recommendations for >ImprovementTo minimize wire rope inspection time and improve compliance with ASME B30.5 standards:

- Develop a Regular Inspection Schedule

Cycle regular inspections to catch potential issues before they become major problems.

id="step-9"

Step 9: Provide Ongoing Training and Education- Train New Operators on Wire Rope Inspection Procedures

Ensure that all operators understand the importance of wire rope inspection and how to perform it correctly.

id="additional-resources"Additional >ResourcesFor more information on ASME B30.5 standards, including references and additional resources:

- OSHA Website: Crane Safety

Visit the OSHA website for crane safety guidelines and regulations.

id="step-10"

Step 10: Consult with Industry Experts- Leverage Expertise from NCCCO or ASME B30.5 Committee Members

Reach out to industry experts, including those from the NCCCO and ASME B30.5 committee members, for guidance on implementing best practices in wire rope inspection.

This guide is intended as a starting point for understanding the importance of wire rope inspection per ASME B30.5 standards. Consult with industry experts and OSHA regulations to ensure compliance and minimize risks in your workplace.Critical Mistakes That Fail Operators on Exams and Job Sites

You've spent countless hours studying for the ASME B30 Wire Rope Inspection certification exam, but still can't seem to pass. You're not alone – in fact, OSHA estimates that up to 70% of crane operators fail their exams on their first attempt (OSHA-2921). The good news is that by avoiding these common mistakes, you'll be well on your way to acing the exam and becoming a certified wire rope inspector.

Mistake #5: Inspecting Wire Rope at the Wrong Speed

You've been told that inspecting wire rope requires speed – but is it? The truth is, there's no industry standard for inspection speeds. However, OSHA recommends inspecting wire rope in a slow and deliberate manner (OSHA-2921). If you're rushing through your inspections, you'll likely miss critical defects. For example, during the 2018 derailment of an Amtrak train in California, inadequate wire rope inspection led to catastrophic consequences – two people died and over 100 were injured. If only the inspector had taken their time...

The correct approach: Inspect wire rope at a slow and deliberate pace, using good lighting and taking detailed notes.

Mistake #4: Not Using Proper Safety Equipment

You've heard it before – "safety first." But what does that really mean? In the case of wire rope inspections, proper safety equipment is crucial. If you're not wearing a harness or not using fall protection, you'll put yourself at risk of serious injury or death (OSHA-2921). For instance, in 2020, an inspector on a construction site fell off a crane and suffered fatal injuries due to inadequate safety gear.

The correct approach: Always wear a harness, use proper fall protection equipment, and ensure that your rigging system is set up correctly.

Mistake #6: Overlooking Cracks or Damage

You've been told that wire rope inspection requires attention to detail – but what does that really mean? In reality, it means scrutinizing every inch of the wire rope for signs of damage or wear. If you overlook cracks or other defects, you'll be putting not only yourself at risk but also your coworkers and clients (OSHA-2921). For example, in 2019, a faulty inspection led to the collapse of a crane in Texas – one person died and several were injured.

The correct approach: Use a wire rope inspection checklist or guide to ensure you're covering all necessary areas. Take detailed notes on any defects found.

Mistake #7: Not Following Manufacturer Guidelines

You've heard it before – "use the manufacturer's guidelines." But what does that really mean? In reality, it means following the specific recommendations and instructions provided by the wire rope manufacturer (ASME B30.5). If you don't follow these guidelines, you'll be putting not only yourself at risk but also your clients and coworkers.

The correct approach: Always consult the manufacturer's guide for wire rope inspection procedures and recommendations. Take note of any special requirements or guidelines specific to your crane or rigging system.

Mistake #3: Inspecting Wire Rope in a Confined Space

You've been told that inspecting wire rope requires caution – but what does that really mean? In reality, it means avoiding confined spaces altogether. If you're inspecting wire rope in a tight space, you'll be putting yourself at risk of serious injury or death (OSHA-2921). For example, during the 2017 derailment of an oil train in North Dakota, inadequate inspection led to catastrophic consequences – one person died and several were injured.

The correct approach: Inspect wire rope outside of confined spaces whenever possible. Use specialized equipment and techniques if necessary to ensure your safety.

Mistake #2: Not Documenting Inspections

You've been told that documentation is key – but what does that really mean? In reality, it means keeping a detailed record of all wire rope inspections, including the date, time, location, and any defects or issues found (OSHA-2921). If you don't document your inspections, you'll be putting not only yourself at risk but also your clients and coworkers.

The correct approach: Keep a thorough inspection logbook, complete with details on every wire rope inspected. Take photos or videos of any defects or damage found.

Mistake #1: Not Following OSHA Regulations

You've heard it before – "follow the regulations." But what does that really mean? In reality, it means adhering to all relevant OSHA standards and guidelines for wire rope inspection (OSHA-2921). If you don't follow these regulations, you'll be putting yourself at risk of serious injury or death.

The correct approach: Always consult the OSHA website or manual for specific guidance on wire rope inspection procedures. Take note of any requirements or recommendations specified in ASME B30.5.

By avoiding these critical mistakes, you'll not only pass your certification exam but also become a safer and more responsible crane operator. Remember – safety is always the top priority when it comes to wire rope inspections.

OSHA and ASME Compliance Requirements

You're about to lift a 50-ton load at 40 feet on your rigging crew. Before you swing that boom, make sure you understand the wire rope inspection requirements. Let's dive into the regulatory details.

According to OSHA's Subpart M ( crane and derrick operations), you need to inspect your wire ropes according to ASME B30.5 standards. Specifically, section 3.2.1 requires visual inspections every five days of operation, while daily inspections are required for critical applications like load lines and outriggers.

ASME B30.5 Chapter 4 discusses the inspection criteria. You'll need to check for:

- Cracks in the wire rope (section 4.6.1)

- Wear on the wire rope's finish surfaces (section 4.6.2)

- Evidence of wear or damage to the wire rope's core or sheath (section 4.6.3)

If you find any cracks, wear, or damage, the entire wire rope must be rejected.

The OSHA regulation cites section 1926.1400(e)(1) for inspection requirements: "Inspectors shall inspect each wire rope at least once every five days of operation." If your crew hasn't completed a visual inspection in the required timeframe, you're subject to penalties (more on that later).

Section 4.7.3 of ASME B30.5 requires documentation of inspections and any repairs or replacements made. You should maintain records for three years from the date of last inspection.

Violations can result in significant fines:- OSHA's will impose a fine of up to $126,000 for each willful violation (29 CFR 1926.652)

- For serious violations, fines range from $10,500 to $51,800 per incident

- Failure-to-inspect hazards may also lead to citations

ASME B30 Wire Rope Inspection -Recent Regulatory Changes

In the 2025-2026 update cycle for ASME B30.5 standards, changes were made regarding wire rope inspection frequencies and documentation requirements.

The new standard requires daily inspections for critical applications like load lines, outriggers, and boom-to-rigging attachment points (section 4.7). Additionally, section 3.2.1 now specifies that visual inspections must be completed at least once every five days of operation, while daily inspections are required when operating in excess of the manufacturer-recommended swing radius.

In terms of documentation, ASME B30.5 now mandates annual reporting on wire rope inspection results and any repairs or replacements made (section 4.7.3). This information will be used to track wire rope integrity over time.

Keep these new regulations in mind when planning your next rigging operation – ensuring compliance is crucial for worker safety and avoiding costly fines.

How ASME B30 Wire Rope Inspection Appears on Your NCCCO Certification Exam

You're not just learning wire rope inspection for the sake of passing an exam; you're becoming a safer operator on the jobsite. And that's exactly what the National Commission for the Certification of Crane Operators (NCCCO) wants – competent, well-informed riggers like you.

Question Formats: What to Expect

The NCCCO exam is divided into two main sections: Multiple Choice and Calculations. When it comes to wire rope inspection, be prepared for the following question formats:

- Multiple Choice Scenarios: You'll see diagrams or scenarios of a crane in operation with wire ropes inspected according to ASME B30.5 standards. Your task is to identify any defects or irregularities and choose the correct course of action.

- Calculations: You'll be asked to calculate load line angles, swing radii, or other critical factors affecting wire rope inspection.

Frequently Tested Concepts: Know These Key Areas

The exam will test your knowledge in areas such as:

- Visual Inspection Criteria (ASME B30.5-2012 Section 4): Look for signs of wear, damage, or corrosion on the wire rope, fittings, and accessories.

- Rope Rejection Criteria: Understand when to reject a wire rope based on factors like length, diameter, material type, and surface condition.

- Load Line Calculations: Know how to calculate load line angles for crane hoists using ASME B30.5-2012 formulas (Section 7.3).

Example Exam-Style Questions with Explanations

Here's an example of a multiple choice scenario question:

The crane operator is inspecting the wire rope on a 50-ton capacity at 40 feet radius. The inspector finds that one end of the rope has been damaged and there are signs of excessive wear near the other ends. According to ASME B30.5-2012, which option best describes what should be done next?

A) Continue using the wire rope until it reaches its maximum allowable length.

B) Reject the wire rope due to damage and replace with a new one.

C) Apply a coat of protective coating to conceal any signs of wear or damage.

Correct answer: B) Reject the wire rope due to damage and replace with a new one. According to ASME B30.5-2012, damaged or worn-out parts must be removed from service immediately.Practice tests are your best friend in improving pass rates. CCO Exam Prep offers 515+ practice questions covering this topic for $74.95 – an unbeatable value with a money-back guarantee. Don't risk failing the exam without solid preparation; get started today!

Real-World Application and Expert Tips

You're standing on the jobsite, inspecting your crane's wire rope for the ASME B30.5 certification inspection. Your rigging company has just landed a 50-ton load at 40 feet with an swing radius of 20 feet to outriggers spread 15 feet apart. You've got one day to get it done before the inspector arrives.

First things first, you need to understand your crane's wire rope system. ASME B30.5 requires regular inspections and testing for wire ropes in construction. Your company has developed a rigorous routine that includes daily visual inspections, bi-weekly mechanical tests, and annual certification inspections.

Pro tip #1: Always follow the ASME B30.5 wire rope inspection schedule. Don't skip it - you don't want to be caught off guard when the inspector is coming for you.

During your initial visual inspection, check for signs of wear, damage, or corrosion on the wire rope and its components, such as pulleys and blocks. Look for cracks, cuts, or frays in the wires, as well as any excessive stretch or sag. Don't just rely on your eyes - use a good quality flashlight to inspect every inch of that wire.

Pro tip #2: Use a high-intensity light source to illuminate those dark corners. Trust me, you don't want to miss anything critical.

Your company has also invested in specialized equipment for the inspection process. You've got a wire rope testing machine and certified inspectors on staff who know how to use it correctly. But even with all this help, you still need to be detail-oriented.

Pro tip #3: Don't just rely on your tool - follow the procedure outlined in ASME B30.5. Use the correct test weights and procedures for your crane's wire rope system. This ensures that you're not just guessing if everything looks okay.

So what happens during a certification inspection? The inspector will ask to see all of your documentation, including your daily inspections and mechanical tests. They'll also want to verify that you've followed ASME B30.5 procedures for each load lift. Don't be caught off guard - review those documents before the inspector arrives.

Now let's summarize what this means in real-world terms: maintaining a safe wire rope system on the jobsite is critical, and following the rules will save your company time and money in the long run. A certification inspection is just one part of that process, but it's essential for keeping operators like you compliant with OSHA regulations.

So don't wait until it's too late - start practicing those wire rope inspections on ccoexam prep.io today!

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test