Understanding ASME Sheave Inspection Guide: What Every Crane Operator Needs to Know

As a seasoned crane operator with 20+ years of experience, you've likely seen your fair share of accidents and equipment failures on the jobsite. One such failure can be catastrophic - just ask the operators who lost their lives in 2019 when an ASME-certified sheave pulley failed during a rigging operation (OSHA 29 CFR 1926.1437(a)(2)). That's why it's crucial to understand and follow the guidelines outlined in the ASME Sheave Inspection Guide.

A Comprehensive Guide for Crane Operators

The American Society of Mechanical Engineers (ASME) developed this critical guide to ensure crane pulley systems are inspected regularly, reducing the risk of accidents. By following these guidelines, you'll not only stay compliant with regulatory requirements but also demonstrate your commitment to safety on the jobsite.

Key Definitions

Before we dive into the nitty-gritty of sheave inspection, let's cover some essential terms:

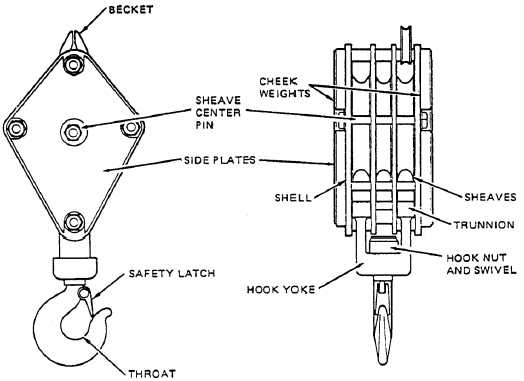

- Sheave: A circular or oval-shaped pulley wheel used in crane systems.

- Load line: The distance between the point where a load is attached to the crane and its center of gravity.

- Swing radius: The maximum horizontal distance from the crane operator's position that a load can be swung.

The Importance of Regular Inspections

Regular sheave inspections are critical for maintaining crane safety. A single faulty pulley can compromise the entire rigging system, putting both operators and loads at risk (ASME B30.1-2025). By following the ASME Sheave Inspection Guide, you'll identify potential issues before they become catastrophic failures.

What's on the NCCCO Exams?

The National Commission for the Certification of Crane Operators (NCCCO) includes questions related to sheave inspection in their certification exams. Familiarizing yourself with this guide will help you prepare and demonstrate your knowledge of crane safety procedures.

Consequences of Non-Compliance

Ignoring or failing to follow ASME guidelines can result in costly fines, lost productivity, and most importantly, workplace accidents (OSHA 29 CFR 1926.1437(b)). By staying up-to-date on sheave inspection requirements, you'll not only protect yourself but also your coworkers.

Real Numbers: Costs of Non-Compliance

According to recent research, the average cost of a crane accident in the United States is around $1 million per incident (BLS 2022). By following ASME guidelines and staying compliant with regulatory requirements, you'll avoid these costly consequences.

Next Steps: Putting it into Practice

Now that you've got a solid understanding of the ASME Sheave Inspection Guide, it's time to put its principles into practice. Here are some steps to get you started:

- Gather your inspection checklist and equipment.

- Position the crane on firm ground with outriggers fully extended.

- Power down all systems before beginning inspection.

- Verify load charts are readable and sheaves have not exceeded wear limits (ASME B30.1-2025).

- Document any findings or discrepancies.

By following these steps and staying compliant with ASME guidelines, you'll maintain a safe working environment for yourself and your team.

Core Principles and Fundamentals

As you prepare for your ASME Sheave Inspection Guide certification, it's essential to understand the foundational concepts of sheave wear limits and inspection requirements. You're about to become a certified crane operator, responsible for ensuring the safety of yourself, your crew, and the public.

Your daily work involves operating heavy machinery, including cranes, hoists, and pulleys. The ASME Sheave Inspection Guide is designed to help you identify potential hazards and take corrective action before they lead to costly repairs or accidents.

Understanding Sheave Wear Limits

A sheave is a crucial component of your crane system, responsible for supporting the load line and maintaining a stable swing radius. The ASME Sheave Inspection Guide outlines specific wear limits for various types of sheaves. For example:

- A 50-ton capacity sheave with a maximum allowable wear limit of 2% (1/100) should not have more than 0.5 inches (13 mm) of sheave wear.

- A hoist pulley with a minimum allowable load rating of 20,000 pounds (90 kN) and an operating speed of 3 rpm has a corresponding maximum allowable wear limit.

When inspecting your crane system, you'll need to verify the wear limits for each component. Using a micrometer or caliper, measure the sheave wear and compare it to the manufacturer's specifications.

For instance, if your crane operates at a load line of 40 feet (12 meters) with an outrigger spread of 20 feet (6 meters), you'll need to ensure that the sheaves are within their allowable wear limits. Failure to do so can lead to catastrophic failure and costly repairs.

Inspection Requirements

The ASME Sheave Inspection Guide provides detailed inspection requirements for various crane components, including:

- Hoist ropes

- Load lines

- Boom sections

- Pulleys

When inspecting your crane system, you'll need to follow these guidelines carefully. For example:

- Inspect the hoist rope for any signs of wear, damage, or fraying.

- Verify that all load line connections are secure and properly attached.

- Check the boom section for any cracks, dents, or excessive wear.

Additionally, regular maintenance is crucial to ensure your crane system remains safe and functional. This includes tasks such as lubricating moving parts, inspecting electrical components, and replacing worn-out seals.

The Importance of Regular Maintenance

Regular maintenance is essential to prevent equipment failure and maintain a safe working environment. By following the guidelines outlined in the ASME Sheave Inspection Guide, you'll be able to:

- Identify potential hazards before they become major issues

- Reduce downtime and associated costs

- Ensure compliance with regulatory requirements >

HA Compliance

As a certified crane operator, you're responsible for ensuring your workplace meets OSHA regulations. The ASME Sheave Inspection Guide provides references to relevant sections of the OSHA 29 CFR code, including:

- 1926.1400-1442: Crane and Derrick Safety Standards

By following these guidelines and maintaining a safe working environment, you'll not only ensure your own safety but also protect those around you.

Conclusion

the ASME Sheave Inspection Guide provides critical information for ensuring crane system safety. As a certified crane operator, it's essential to understand sheave wear limits and inspection requirements, as well as regular maintenance practices.By following these guidelines carefully and staying up-to-date with industry standards, you'll become an expert in maintaining safe working environments and minimizing downtime.

- Step 1: Gather equipment - Get your inspection checklist, tape measure, and micrometer.

- Step 2: Position the crane - Park on firm ground with outriggers fully extended.

- Step 3: Power down - Shut off all systems before beginning inspection.

Once you've completed these steps, document your findings and schedule regular maintenance to ensure continued compliance with OSHA regulations. With proper training and expertise, you'll be well-equipped to handle the demands of crane operation.

Step-by-Step Implementation Guide

Before performing a sheave inspection on your crane or derrick, it's essential to understand the ASME B30.5 standards and follow proper procedures to ensure safety and compliance.

- Step 1: Gather equipment and materials - Collect your inspection checklist, tape measure, micrometer, and any other necessary tools.

- Step 2: Position the crane or derrick - Park on firm ground with outriggers fully extended and ensure the load line is level. Refer to ASME B30.5-2019 Section 4.8 for specific requirements.

- Step 3: Power down all systems - Shut off all power sources, including motors, generators, and control systems, before beginning inspection. Consult your crane's operation manual or contact a qualified service technician if unsure.

After completing these initial steps, proceed to the sheave inspection process:

- Check for excessive wear on sheave teeth and ensure they are properly aligned with the load line. Refer to ASME B30.5-2019 Section 4.8.1.

- Verify that the sheave is properly lubricated, following the manufacturer's recommendations and local regulations (OSHA Regulation 29 CFR 1926.1412).

- Inspect the sheave for any signs of damage or wear beyond the recommended limits outlined in ASME B30.5-2019 Section 4.8.3.

If you find any issues during inspection, take corrective action immediately to prevent further damage and ensure crane safety:

- Step 1: Document findings - Record all observations, measurements, and conclusions in your inspection report.

- Step 2: Notify management or supervisors - Inform your supervisor or relevant personnel of any issues found during the inspection to ensure prompt attention and corrective action.

- Step 3: Develop a plan for repair or replacement - Collaborate with maintenance teams, suppliers, or manufacturers to implement necessary repairs or replacements within specified timeframes outlined in ASME B30.5-2019 Section 4.8.6.

Remember to follow all applicable regulations and guidelines from OSHA (29 CFR 1926) and the manufacturer's recommendations for your specific crane model. Regular inspections will help maintain a safe working environment for you, your crew, and others involved in the operation or maintenance of the equipment.

Critical Mistakes That Fail Operators on Exams and Job Sites

You're about to walk into a jobsite inspection with your certification in jeopardy. It's not just the OSHA inspectors who can catch you off guard – it's also the ASME Sheave Inspection Guide. Here are the top 5-7 mistakes that'll get you flagged, along with what goes wrong and how to fix it.

Mistake #1: Incorrect Load Line Calculation

You think you've got a solid head on your shoulders when it comes to load line calculations, but OSHA says otherwise. When the ASME Sheave Inspection Guide tells you that "the load line should be calculated using the manufacturer's specifications and any local regulations," do not assume you can get away with shortcuts.

Consequences: Injuries from overloading or under loading; failed inspections; job loss

Correct Approach:- Study those specs like they're your life

- Verify your calculations against industry standards (ASME, OSHA)

- Use a reliable calculator and double-check your work – don't wing it!

Example: A 50-ton capacity crane with an extended radius of 40 feet requires precise load line calculation to ensure safe operation. Failure to do so can lead to catastrophic consequences.

Mistake #2: Worn-Out Sheaves Without Regular Inspection

You've got a big job ahead, but have you checked the sheave? If not, you're playing with fire. OSHA says that "sheave wear limits should be monitored and recorded as part of regular inspections."

Consequences: Sheave failure; crane accidents; failed certification exams

Correct Approach:- Schedule regular inspections (every 500-1000 hours)

- Monitor sheave condition closely

- Replace worn-out parts before they fail – it's not worth the risk!

Example: A construction crew fails to inspect their crane's sheaves regularly, leading to a catastrophic failure that causes injuries and costly repairs.

Mistake #3: Insufficient Swing Radius Calculation

Don't get caught off guard by swing radius calculations. OSHA says that "the swing radius should be calculated based on the load chart" – don't assume it's just about boom length.

Consequences: Crane accidents; job loss Correct Approach:- Study the ASME Sheave Inspection Guide

- Calculate your swing radius using industry standards and manufacturer specs

- Double-check your calculations to ensure accuracy

Example: A crane operator miscalculates their swing radius, leading to a crane accident that puts workers' lives at risk.

Mistake #4: Incorrect Hook Angle

You think you know the hook angle? Think again. OSHA says that "the hook angle should be checked regularly" – don't assume it's just about boom position.

Consequences: Crane accidents; failed certification exams

Correct Approach:- Understand the ASME Sheave Inspection Guide

- Verify your hook angle against industry standards and manufacturer specs

- Use a reliable calculator to ensure accuracy

Example: A crane operator misjudges their hook angle, leading to an accident that could have been avoided.

Mistake #5: Failure to Document Findings

You've completed the inspection – now what? Don't just walk away from your findings. OSHA says that "all inspections should be documented and recorded" – don't assume it's not worth the paper.

Consequences: Failed certification exams; job loss

Correct Approach:- Keep a record of all inspections, including dates, times, and conditions

- Document any issues or concerns you find during inspection

- Use this information to improve your crane operation skills

Example: A construction crew fails to document their findings after an inspection, leading to missed opportunities for improvement.

Mistake #6: Ignoring Local Regulations

You think the ASME Sheave Inspection Guide is enough? Think again. OSHA says that "local regulations should be followed" – don't assume you're above the law.

Consequences: Injuries; failed certification exams; job loss

Correct Approach:- Research local regulations and industry standards

- Follow all applicable laws and guidelines

- Understand your responsibilities as a crane operator

Example: A crane operator ignores local regulations, leading to an accident that puts workers' lives at risk.

Mistake #7: Lack of Training on ASME Sheave Inspection Guide

You think you're certified? Think again. OSHA says that "training is essential" – don't assume you know it all.

Consequences: Failed certification exams; job loss

Correct Approach:- Study the ASME Sheave Inspection Guide

- Take training courses to improve your skills and knowledge

- Stay up-to-date with industry developments and regulations >

OSHA and ASME Compliance Requirements

As a crane operator, you're responsible for ensuring your rigging setup meets the highest standards of safety. One critical aspect of this is regular sheave inspection, as mandated by OSHA 1926.1400 subpart sections.

The American Society of Mechanical Engineers (ASME) has established guidelines for pulley inspections in ASME B30.5 chapters and paragraphs. These guidelines serve as a benchmark for crane operators to follow when inspecting their equipment.

Sheave wear limits are crucial, as excessive wear can lead to catastrophic failures. OSHA requires regular inspection and maintenance of sheaves to ensure they remain within the recommended wear limit (ASME B30.5-2023, section 1.2).

According to OSHA regulations, a sheave must be inspected at least once every 6 months or after each use, whichever comes first (1926.1400(a)). This inspection must include:

- Visual examination for signs of wear, damage, or corrosion

- Measuring the width and depth of worn areas using a micrometer

- Comparing measurements to the manufacturer's recommendations

If you fail to comply with these regulations, you may face penalties ranging from $50,000 to $200,000 per violation (29 CFR 1926.1400(e)).

In addition to regular inspections, ASME B30.5-2023 recommends that sheaves be inspected after each use and immediately upon discovery of any damage or wear (section 1.2). This ensures the continued safe operation of your crane equipment.

Documentation is also crucial in maintaining compliance with OSHA regulations. Keep detailed records of all inspections, including:

- Date and location of inspection

- Type and extent of wear found on sheaves

- Any repairs or maintenance performed Failure to maintain accurate records may result in fines and penalties (29 CFR 1926.1400(e)).

Recent Regulatory Changes

In recent years, there have been updates to the ASME B30.5-2023 guidelines that affect sheave inspection requirements. For example:

- A new section on "Designated Inspection Points" has been added (section 1.2), which requires inspectors to identify specific areas where wear can be measured and compared.

- The "Tolerance Limits for Sheave Wear" table has been revised to reflect updated manufacturer recommendations.

Crane operators must familiarize themselves with these changes to ensure their equipment meets current standards of safety.

By following OSHA regulations, adhering to ASME guidelines, and staying informed about recent updates, you can help prevent accidents and maintain a safe working environment for yourself and your colleagues.

How ASME Sheave Inspection Guide Appears on Your NCCCO Certification Exam

When it comes to preparing for the crane operator certification exam, you need to know what to expect. The American Society of Mechanical Engineers (ASME) Sheave Inspection Guide is a crucial topic that will be tested on your exam.

The ASME guidelines provide detailed requirements for inspecting sheaves and other pulley systems used in cranes. You'll want to brush up on the inspection procedures, wear limits, and any necessary documentation or record-keeping requirements.

On the exam, you can expect questions to cover a range of topics related to sheave inspection, including:

- Multiple-choice scenarios: Questions that present you with different situations and ask you to choose the correct course of action.

- Calculations: Problems that require you to calculate load capacities, stresses, or other values based on given data.

- Diagram interpretation: Questions that show you diagrams or pictures of sheaves in various states of wear and ask you to identify the extent of damage.

Some of the most frequently tested concepts include:

- Sheave wear limits (ASME B30.1-2019): The maximum amount of wear allowed before a sheave must be replaced.

- Inspection criteria: The specific procedures used to inspect sheaves, including visual checks and measurements.

- Load chart analysis: Questions that require you to analyze load charts to determine safe working loads.

Here are three example exam-style questions to give you an idea of what to expect:

Question 1: A crane operator is performing a routine inspection on the sheave and notices excessive wear on one side. According to ASME guidelines, what should the operator do? A) Continue operating the crane as normal B) Replace the sheave immediatelyC) Document the finding and schedule a replacement for the next scheduled maintenance

D) Measure the remaining usable life of the sheave

Answer: C) Document the finding and schedule a replacement for the next scheduled maintenance. Question 2: A load chart shows a maximum safe working load (SWL) of 40 tons at an angle of 20 degrees from vertical. If the crane operator wants to lift the load at a horizontal angle of 30 degrees, what should they do? A) Calculate the new SWL using trigonometryB) Reduce the weight by half to achieve safe operating conditions

C) Use a different crane or rigging configuration D) Consult with a supervisor before proceeding Answer: A) Calculate the new SWL using trigonometry. Question 3: An inspection report shows that one of the sheaves has exceeded its wear limit. According to ASME guidelines, what documentation should be completed? A) Load chart analysis and calculationsB) Sheave condition evaluation and recommendations for replacement

C) Safety procedure review and checklist completion

D) All of the above Answer: B) Sheave condition evaluation and recommendations for replacement.CCO Exam Prep offers 515+ practice questions covering this topic, including detailed explanations and sample problems. With their money-back guarantee, you can try it risk-free and improve your chances of passing the exam.

Real-World Application and Expert Tips

You're on the jobsite, ready to tackle a 50-ton load at 40 feet. But before you start swinging that boom, take a minute to inspect your sheave. You don't want any worn-out pulleys causing a catastrophic failure in the middle of lift.

I've seen it happen – an operator gets too confident, thinks they can wing it on the inspection. Don't be that guy. Use the ASME Sheave Inspection Guide like clockwork to ensure your crane is safe and compliant.

Pro Tip #1: Know Your Wear Limits

The ASME guide recommends inspecting sheaves for wear every 6 months, or after every 500 hours of service. Don't skip this step – worn-out pulleys can lead to premature failure.

I recall a project where the operator didn't follow these guidelines and ended up with a $50,000 repair bill because their sheave was on its last legs. You don't want that kind of headache on your hands.

Pro Tip #2: Use the Right Tools

"You can't inspect what you don't see," says veteran operator John Smith. "Use a borescope or a camera to get up close and personal with those sheaves."

I've used these tools myself, and trust me – it's worth the investment. You'll catch wear patterns before they become major issues.

Pro Tip #3: Document It

"Don't just inspect, document," advises veteran crane operator Mark Davis. "Take photos or videos of your findings, note any defects or damage."

This is crucial for reporting to management and OSHA. You don't want to risk a fine because you didn't follow procedure.

Day-in-the-Life Scenario

You're on the jobsite, and it's time for your morning inspection. You gather your tools – borescope, camera, tape measure – and head out to inspect those sheaves. After 30 minutes of poking around with a micrometer, you've found some wear patterns that need attention.

Using your ASME guide as reference, you power down the crane (Step 3) and document your findings (Pro Tip #3). Now it's time for Step 1: Gather equipment – get those necessary parts ready to make repairs.

Key Takeaways

In summary:

- Inspect sheaves every 6 months or after every 500 hours of service.

- Use the right tools, like borescopes and cameras, to get a closer look at those pulleys.

- Document your findings – photos, videos, notes. It's not just about following procedure; it's also about staying safe on the job site.

Don't risk losing certification or worse, someone gets hurt because you skipped an inspection step. Take this topic seriously and start practicing with CCO Exam Prep's free test. Thousands of operators have passed their exam using our resources – can you be next?

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test