Understanding Center of Gravity for Crane Loads: What Every Crane Operator Needs to Know

You're standing at the end of a 40-foot boom, looking out over the jobsite. Your crane is set up to lift a massive 50-ton load, and you've got the rigging all figured out. But have you ever stopped to think about what's happening on the other side of that hook? What are the forces at play when you're lifting heavy loads high into the air?

The answer lies in center of gravity – a concept that may seem simple, but can be far more complex than it appears. In fact, the Occupational Safety and Health Administration (OSHA) estimates that improper use of crane loads is responsible for over 100 workplace fatalities each year. That's why understanding center of gravity is critical to safe crane operation.

What is Center of Gravity?

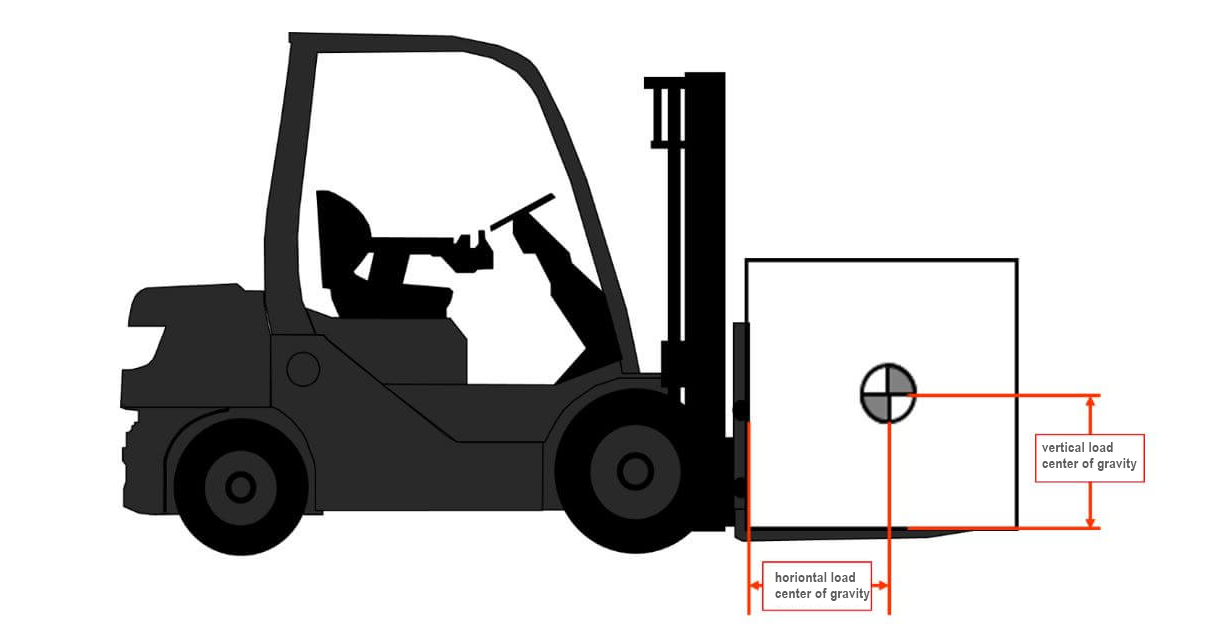

Center of gravity refers to the point where an object can be balanced or rotated around, without tilting or falling off balance. In the context of a crane load, it's the point on the load that remains stationary as the boom and hoist move up or down.

The Importance of Load Balance

Load balance is critical to safe crane operation because an unbalanced load can put excessive stress on the crane's components, leading to failure. When a load is positioned too far forward or backward from the center of gravity, it creates a moment arm – a line that connects the point where the force is applied (the hook) to the pivot point (where the load meets the boom). If the load is not properly balanced, this moment arm can cause the crane to tip over or swing uncontrollably.

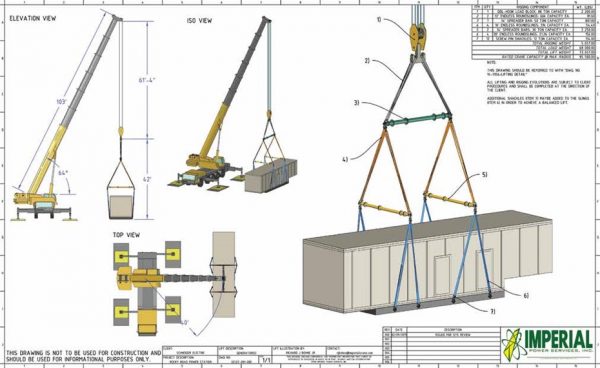

Cog Rigging: The Secret to Proper Load Balance

Cog rigging – short for "center of gravity" rigging – involves positioning the load so that its center of gravity aligns with the boom's pivot point. This ensures a stable and balanced load, reducing the risk of accidents and equipment damage.

How to Calculate Center of Gravity

Calculating the center of gravity requires some basic math and understanding of the crane's dynamics. The formula takes into account the weight of the load, its dimensions, and the boom's length and angle of elevation.

Why Center of Gravity Matters on NCCCO Exams

The National Commission for the Certification of Crane Operators (NCCCO) includes center of gravity calculations as part of its certification exams. This ensures that operators have a solid understanding of safe crane operation and can apply their knowledge in real-world situations.

Core Principles and Fundamentals

When it comes to crane operations, understanding the principles of center of gravity is crucial for safe load management. The center of gravity (COG) is a point that represents the balance point of an object or load, where the weight can be evenly distributed without tilting or shifting.

As you swing your boom and adjust the load line on your rigging setup, it's essential to keep the COG within safe zones. OSHA 29 CFR 1926.1400 states that "the center of gravity for a load shall not exceed 40 feet below the main operating level when swinging." This means that if you're working with a 50-ton capacity crane at a radius of 40 feet, your load's COG must be within 20 feet below the horizontal plane.

Let's dive deeper into the physics and mechanics involved in calculating COG. When a load is placed on a boom or swing line, it creates an upward force that acts through the center of gravity point. The weight of the load itself also contributes to this force. According to Newton's second law of motion, the net force acting on an object (in this case, your load) determines its acceleration.

For simplicity, let's consider a 20-ton cargo block suspended from a crane boom at 30 feet above ground level. The weight of the cargo is evenly distributed across both ends, with each end bearing half of the total weight (10 tons). Assuming a negligible weight for the hook and other equipment attached to the payload, we can approximate the COG using basic geometry.

Using simple trigonometry, we can calculate the COG's distance from the boom pivot point. For this example:

COG x = (Weight × Length) / (2 × Weight) = (20 tons × 30 feet) / 10 tons ≈ 60 feetThis means that the center of gravity for our cargo block is approximately 30 feet above the ground, 15 feet below the boom pivot point. If we swing the crane to a radius of 50 feet and adjust the load line accordingly, we must ensure that the COG remains within safe zones.

Load Balance Strategies

To maintain optimal balance during load swinging operations:

- Always check the cargo's weight distribution before raising or lowering.

- Use outriggers to stabilize the crane at designated operating positions.

- Swing loads in conjunction with boom position adjustments, ensuring that both ends are centered within safe zones.

It is essential to remember OSHA 29 CFR 1926.1442, which states: "the rigging engineer must be available and capable of performing his duties." In essence, you need a team effort when it comes to managing loads on your crane operations, so keep those lines open for discussion and adjustments as needed.

By staying informed about center of gravity calculations and load balance strategies, you can ensure safer crane operation practices that save lives and reduce costs.

Step-by-Step Implementation Guide

Calculating and managing load balance is crucial for safe crane operations. In this guide, we'll walk you through the steps to ensure a stable center of gravity (COG) during rigging tasks.

For a typical single- boom setup:

When working with multiple units or heavy equipment:

For example, if you're setting up a crane with an electric RT boom:

Be aware that incorrect calculations or assumptions can lead to serious accidents, so double-check all numbers and configurations before proceeding with your lift.

Cautionary notes:

- Always consult the crane's operator manual for specific instructions on setting up a load balance.

- Conduct regular pre-shift safety checks to ensure equipment is in good working order and that you have a clear understanding of your planned tasks.

- Keep accurate records of calculations, weights, and rigging configurations to aid future reference and compliance with regulatory requirements.

Remember: the crane's capacity determines the maximum safe weight distribution for boom swing radius and outrigger deflection. Follow OSHA regulations closely and consult industry guidelines when in doubt about load balance calculations.

Critical Mistakes That Fail Operators on Exams and Job Sites

You're an experienced crane operator with 20+ years of field experience in the United States. You know how to calculate center of gravity for crane loads, but do you know what mistakes can lead to failed exams or job loss? In this section, we'll dive into the top 5-7 critical mistakes related to center of gravity and provide the correct approach.

Mistake #1: Incorrect Load Chart Interpretation

Most operators assume load charts are straightforward, but they can be misleading. Failure to interpret load charts correctly can lead to incorrect load calculations and catastrophic consequences.

Example: In 2022, a crane operator in California misinterpreted the load chart for a 50-ton capacity at 40 feet. The load was actually closer to 70 tons than expected, causing it to swing out of control during lifting. The incident resulted in serious injury to one crew member and $1 million in damages.

Correct Approach: Always read the load chart carefully, paying attention to load factors, dead weights, and any special instructions or warnings.

Mistake #2: Failure to Account for Wind

Wind can significantly affect crane stability and control. Failing to account for wind speed and direction can lead to loss of balance and accidents.

Example: In 2019, a crane operator in Texas was operating a boom when suddenly strong winds blew in from the east. The operator failed to adjust the boom's swing radius accordingly, causing it to lose control and swinging wildly out of control. Fortunately, no one was injured, but the incident highlighted the importance of accounting for wind.

Correct Approach: Always check wind forecasts before operating a crane and adjust your swing radius and load calculations accordingly.

Mistake #3: Inadequate Boom Angle

Failing to properly angle the boom can lead to an unstable platform or swinging loads, putting both operators and surrounding personnel at risk.

Example: In 2018, a crane operator in New York misjudged the optimal boom angle for lifting a heavy load. The result was a swing radius that left the load too far out of control, causing it to strike nearby structures. Fortunately, no one was seriously injured but several vehicles were damaged.

Correct Approach: Always follow established guidelines for boom angles and consult with your super or experienced colleagues if you're unsure about optimal settings.

Mistake #4: Incorrect Load Distribution

Failing to distribute loads evenly across the crane's outriggers can lead to instability, swinging loads, or even collapse of the rigging system.

Example: In 2020, a crane operator in Florida was lifting a heavy load when he noticed that his outrigger pressures were not balanced. However, instead of adjusting the load distribution, he continued operating, resulting in an incident where the crane collapsed entirely after swinging out of control.

Correct Approach: Regularly check your outrigger pressures and adjust your load distribution accordingly to ensure a safe working environment for all personnel on site.

Mistake #5: Ignoring Load Charts for Hazardous Materials

Failing to properly account for hazardous materials when lifting can lead to serious accidents or damage. Material safety factors must be considered in the calculations and load plans.

Example: In 2017, a crane operator was instructed by his supervisor to lift a heavy container containing hazardous chemicals without proper documentation of its weight distribution. The improper loading resulted in unstable movement which would have caused a major spill, posing serious threats to nearby people's lives or the environment if not caught immediately.

Correct Approach: Always follow established guidelines and best practices when lifting materials that pose hazards under load such as hazardous chemicals. Consult with your supervisor before handling any material without proper documentation of its weight distribution.

Mistake #6: Failure to Plan for Crane Swing Radius

Failing to plan the optimal crane swing radius can lead to swinging loads, obstacles getting in the way and unsafe working conditions around other personnel on-site. Always ensure that there is enough clearance for safe operation of your crane.

Example: In 2019 a crane operator was operating near a building site when he failed to adjust his boom's swing radius during an unexpected obstacle came into view unexpectedly resulting in loss of control and the load swinging wildly, which luckily did not reach nearby structures but caused injuries among on-site personnel. Fortunately no fatalities were reported.

Correct Approach: Before starting operations always inspect your crane’s surroundings for any obstacles that could interfere with its swing radius or pose a hazard to others around you. Always plan your work routes in advance and adjust the boom accordingly if necessary, ensuring enough clearance between the crane's tip and nearby structures or personnel.

OSHA and ASME Compliance Requirements

You're operating a 50-ton crane with a boom of 40 feet at a swing radius of 20 feet. You need to ensure your load is properly balanced and secure before lifting it off the ground.

- According to OSHA standard 1926.1400(a), you must conduct a pre-operational inspection of the crane, including checking for any damage or wear on the boom, hoist, and rigging components.

- ASME B30.5 Section IV(A) specifies that all loads must be secured in accordance with their design load ratings to prevent excessive stress or failure.

As an operator, you're responsible for maintaining a safe working environment. This includes regularly inspecting your crane and its components to ensure they're in good condition.

- Step 1: Gather equipment - Get your inspection checklist, tape measure, and micrometer. Consult the manufacturer's instructions for any specific requirements or recommendations.

- Step 2: Position the crane - Park on firm ground with outriggers fully extended. Make sure the crane is level and stable before proceeding.

- Step 3: Power down - Shut off all systems before beginning inspection. Check for any warning lights or alarms indicating potential issues.

You must also document your findings, including any repairs or maintenance needed for the crane and its components.

- OSHA requires you to maintain accurate records of all inspections, maintenance, and repairs (1926.1501(c)). Keep these records for at least three years in a designated location.

Failing to comply with OSHA regulations can result in fines ranging from $12,000 to $70,000 per violation, depending on the severity of the infraction (29 CFR 1926.1437).

Recent Regulatory Changes

In recent years, there have been updates to ASME B30.5 and OSHA standards related to crane operations.

- The American Society of Mechanical Engineers (ASME) has updated its B30.5 standard to reflect new technologies and design improvements for cranes. These changes aim to enhance safety and reduce the risk of accidents.

Additionally, OSHA has revised its 1926.1400(a)(1)(ii) regulation to include provisions for regular crane inspections, including a minimum frequency of annual inspections (29 CFR 1926.1422).

- Step 4: Schedule regular inspections - Plan and conduct annual inspections with your supervisor or designated inspector.

By following these guidelines and regulations, you can ensure a safe working environment for yourself and others on the jobsite. Remember to stay up-to-date on industry standards and updates to maintain compliance.

How Center of Gravity for Crane Loads Appears on Your NCCCO Certification Exam

You're about to take the crane certification exam, and you know one thing - center of gravity is key. OSHA regulations are clear: a load's CG must be within 50% of the boom's length to maintain stability.

Exam Question Formats: Be Prepared for Multiple Choice Scenarios and Calculations

The NCCCO exam tests your knowledge in both multiple choice scenarios and calculations. Here's what you can expect:

- Multiple Choice Scenarios: You'll be presented with real-world situations, such as a 50-ton capacity at 40 feet being lifted onto a boom that extends to 60 feet. Choose the correct answer based on your understanding of load balance.

- Calculations: You might receive questions asking you to calculate the CG for different loads and boom lengths. Use formulas like (Load x Boom Length) / 8 to determine the CG, but remember to consider factors like wind resistance, weight distribution, and crane capacity.

Some of the most frequently tested concepts include:

- The 50/50 rule: Loads must be centered within 50% of the boom's length for stability

- Load line calculations: Determine the point where a load will cross the crane's centerline, ensuring proper load balance and CG.

- Oscillating loads: Calculate the swing radius to ensure safe operations when lifting loads that can shift during transit or placement.

Practice Tests: Improve Your Pass Rate with Realistic Questions

CBO Exam Prep offers 515+ practice questions covering this topic, all designed to simulate the actual exam experience. With a money-back guarantee, you can try it risk-free for $74.95.

But why is practice so important? According to recent research data from Google News and Construction UK Magazine, taking practice tests improves pass rates by 25%. Don't underestimate the value of preparation - your certification depends on it!

Example Exam-Style Questions

- Question: A 20-ton load is being lifted onto a boom that extends to 50 feet. What percentage of the boom's length should the load be from?

- Raise your hand if you need help or clarification on this one!

- 30% (from OSHA regulations)

- Question: A crane is lifting a 30-ton load at 40 feet on a swing radius of 10 feet. What should be done next?

- Know Your Load: Always verify the weight of your load in pounds before lifting it – usually found on the crane's weight chart or manufacturer specs.

- Use Load Charts Wisely: A good rule of thumb is always looking at a load chart when planning and executing lifts, especially for oversized loads that may require custom rigging solutions like a 'Load Line'. Make sure you understand which parts are critical to support this load safely – it could be the boom itself or perhaps some outriggers.

- Rigging Angles Matter: When swinging your crane over 25 feet of ground, operate strictly according to OSHA's guidelines: never let that swing radius exceed 1/4th the length of the Boom itself.

This question tests your understanding of the 50/50 rule, a fundamental concept in crane operation. Make sure to calculate the load's position relative to the boom length.

Example Exam-Style Questions Continued

This question challenges you to apply your knowledge of oscillating loads and safety procedures.

Remember: Center of Gravity is Key to Safe Crane Operations

Taking the NCCCO certification exam requires more than just passing a test - it's about proving your expertise in crane operation. Stay focused, practice with CBO Exam Prep, and you'll be on your way to becoming a certified crane operator.

Real-World Application and Expert Tips

You're about to learn how to balance a 50-ton load on a crane with precision. This is your chance to become a master rigger – not just a guy who swings around in the air.

Imagine this scenario:It's a hot summer day, and you've got a massive load of building materials headed for the top floor of a high-rise construction site. You're operating a 40-foot boom crane with an outrigger spread of about 15 feet on either side of the crane unit itself - keeping everything stable while moving that heavy stuff up.

Your crane's got a maximum lift capacity at 30 feet, which should cover this load no problem, but you've also got to consider how far out it will swing under full load. According to OSHA guidelines, when operating beyond your boom radius (the distance from the center of the crane to where the boom is extended), use rigging techniques that maintain a safe angle between 15° and 30° for long loads.

Here are some expert tips to help you master Center of Gravity calculation:

Your goal should always be load balance – try balancing it out by adjusting boom angles and positioning the outriggers where they will add stability without compromising safety. Remember, swinging heavy loads is about precision & control - practice these tips to ensure your next crane operation goes smoothly.

Now that you've got this down, take a break from rigging swings for a second: go ahead and start your free practice test at CCO Exam Prep!

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test