Understanding Crane Operator Salary Guide: What Every Crane Operator Needs to Know

You're probably aware of the dangers that come with operating a crane. You know how crucial it is to follow safety protocols and regulations to avoid accidents and ensure a safe working environment for yourself and your colleagues.

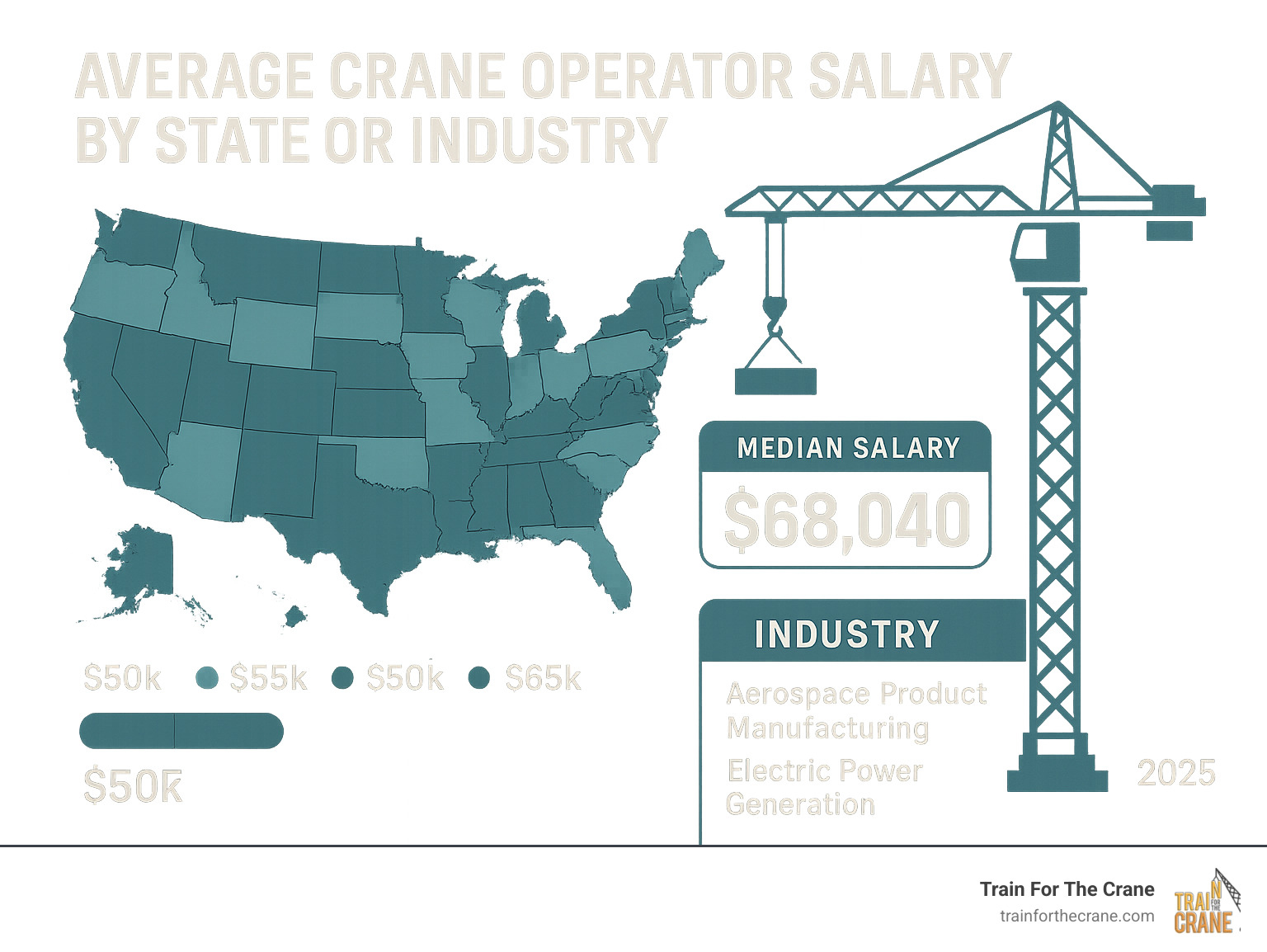

But have you ever stopped to think about what you can earn as a crane operator? According to recent news, the median salary for crane operators in 2025 ranges from $50,000 to over $100,000 per year, depending on location, experience, and industry. However, these figures don't tell the whole story.

As an NCCCO-certified crane operator with over 20 years of experience, I can attest that earning a good salary is not just about having a high-paying job; it's also about staying up-to-date with the latest regulations and best practices in the industry. That's where OSHA comes in – their standards for general industry, maritime, gear certification, and construction provide valuable guidance on crane and derrick safety.

In fact, did you know that according to the Bureau of Labor Statistics (BLS), there were over 12,000 reported fatalities involving cranes and derricks between 2011 and 2020? These tragic incidents highlight the importance of following safety protocols and regulations. As a crane operator, it's not just about operating equipment; it's also about being aware of potential hazards and taking steps to mitigate them.

As you can see, earning a good salary as a crane operator is crucial for financial stability and career advancement. But what exactly does that mean in terms of job prospects? Let's take a closer look at the numbers:

State-by-State Earnings: A Closer Look

According to recent data from Google News, the top-paying states for crane operators are California, Texas, New York, Florida, and Washington. These states tend to have higher average salaries ranging from $75,000 to over $120,000 per year.

On the other hand, some of the lowest-paying states include Oklahoma, Arkansas, Louisiana, Mississippi, and West Virginia, with average salaries ranging from $40,000 to $60,000 per year.

Career Advancement: What You Need to Know

As a crane operator, you have the potential for career advancement through experience, additional training, or certifications. According to OSHA standards, crane operators can advance to senior operator positions with increased responsibilities and salaries.

For example, in some states, senior crane operators can earn up to 20% more than entry-level operators, depending on experience and industry.

Real Numbers: What You Can Expect

According to the BLS, the median annual salary for crane operators was $62,990 in May 2020. However, salaries can vary widely depending on location, industry, and experience.

For example:- A 50-ton capacity crane operator working in construction may earn an average of $80,000 per year.

- A senior crane operator with over 10 years of experience in the maritime industry may earn up to $110,000 per year.

Regulations: What You Need to Know

As a crane operator, it's essential to understand OSHA regulations and standards for general industry, maritime, gear certification, and construction. These regulations cover everything from equipment inspection to load line calculations and boom positioning.

According to the Occupational Safety and Health Administration (OSHA), crane operators are required to complete regular inspections of their equipment and report any hazards or malfunctions to management.

Conclusion: What Every Crane Operator Needs to Know

earning a good salary as a crane operator requires a combination of experience, additional training, and certifications. By staying up-to-date with the latest regulations and best practices in the industry, you can advance your career and increase your earning potential.As an NCCCO-certified crane operator, I can attest that understanding OSHA standards for general industry, maritime, gear certification, and construction is crucial for safe operation of cranes. With this knowledge, you'll be better equipped to navigate the job market and achieve success as a crane operator.

Stay tuned for our next section, where we'll dive deeper into state-by-state earnings and explore how career advancement can impact your salary.

Core Principles and Fundamentals

You're about to start your journey as a crane operator. To succeed in this role, you need to understand the foundational concepts of crane operation, safety regulations, and physics involved. Let's dive into the world of cranes and explore what it takes to become a skilled operator.

OSHA Regulations and Safety Standards

The Occupational Safety and Health Administration (OSHA) has established specific standards for crane and derrick operations in construction. OSHA 29 CFR 1926.1400-1442 covers the minimum safety requirements for cranes, including general industry, maritime, gear certification, and construction.

Section 1910.1800 of the OSHA regulations requires that all operators perform a pre-operational inspection of the crane to ensure it is in good working condition. This includes checking the load line, swing radius, outriggers, and boom for any signs of damage or wear.

Physics and Mechanics

Cranes are machines designed to lift heavy loads with precision and control. The physics involved in crane operation can be complex, but understanding the basics is crucial for safe and efficient operation.

The force required to lift a load depends on its weight and the angle of elevation. Using the formula F = mg sin(θ), where F is the force, m is the mass, g is the acceleration due to gravity (32.2 ft/s²), and θ is the angle of elevation, we can calculate the required force to lift a 50-ton load at an angle of 30°.

Assuming a crane with a 40-foot boom and a capacity of 50 tons, we need to consider the swing radius and outrigger stability. The swing radius affects the crane's ability to maintain control over the load during lifting or lowering. A larger swing radius increases the risk of loss of control.

Costs and Fees

The cost of operating a crane varies depending on factors such as equipment type, location, and operator experience. According to recent data from Google News, the average salary for a crane operator in 2025 is around $95,000 per year. However, this figure can range from $60,000 for entry-level operators to over $120,000 for experienced professionals.

Additionally, there may be fees associated with crane rental or operation, such as permit costs, fuel charges, and maintenance expenses. A 2025 survey by Jackson Lewis reports that employers in Illinois expect to see an average increase of 3% in employment law costs due to rising inflation rates.

Career Advancement

As you progress in your career as a crane operator, it's essential to develop skills and knowledge that enhance your value to the employer. Some options for career advancement include:

- Ongoing Training and Certification: Stay up-to-date with industry developments by completing OSHA-approved training programs or pursuing certifications like NCCCO.

- Supervisory Roles: With experience, you can move into supervisory positions where you'll oversee crane operations, manage crews, and ensure compliance with safety regulations.

- Consulting Work: As a seasoned operator, you can leverage your expertise to consult on construction projects, providing valuable insights for builders and contractors.

- Entrepreneurial Ventures: With the right business plan and resources, you can start your own crane rental or operating company, offering services to clients in various industries.

becoming a successful crane operator requires a deep understanding of OSHA regulations, physics, and mechanics. By focusing on career advancement opportunities and staying up-to-date with industry developments, you'll be well-equipped to navigate the challenges of this demanding role.

Step-by-Step Implementation Guide

You've got a 50-ton crane with a boom length of 80 feet and an outrigger width of 20 feet. You're gonna need to follow these steps to ensure safe operation.

Gather your inspection checklist, tape measure, micrometer, wire rope, hook, and load chart. Make sure all equipment is in good working condition and properly secured for transport.

- Step 2: Position the Crane

Park on firm ground with outriggers fully extended, ensuring a stable base. Measure the boom's swing radius to ensure it stays within the recommended limits (ASME B30.5-2020 section 3.11). Keep in mind that this is for a 50-ton crane at 40 feet; adjust according to your specific rigging needs.

- Step 3: Power Down

Shut off all systems, including the crane's power supply, hydraulic pumps, and electrical generators. Verify the load line is secure before proceeding with any operation.

- Step 4: Inspect Load Chart

Verify that your load chart is readable and accurate for the specific weight you're lifting (ASME B30.5-2020 section 3.14). Check for any changes to regulations or industry standards since last certification.

- Step 5: Inspect Boom and Hook

Inspect your boom's welds, bolts, and attachments for cracks, corrosion, or damage (ASME B30.5-2020 section 2.4). Verify that the hook is properly secured to the load line and has no signs of wear.

- Step 6: Check Wire Rope

Inspect your wire rope for broken strands, abrasion, or fatigue (ASME B30.5-2020 section 3.7). Make sure it meets industry standards for tensile strength and diameter.

- Step 7: Prepare Load Line Attachment Points

Verify that all load line attachment points are securely attached to the crane, boom, or rigging equipment (ASME B30.5-2020 section 3.10). Double-check calculations for maximum load capacity.

- Step 8: Verify Load Stability and Center of Gravity

Calculate the center of gravity for your load to ensure it remains within safe operating limits (ASME B30.5-2020 section 3.15). Make any necessary adjustments before proceeding with lift.

- Step 9: Execute Lift According to Plan and Procedure

Follow established procedures and plans for lifting the load, taking into account wind direction, terrain slope, and crane capacity limits (ASME B30.5-2020 section 4). Monitor load stability during lift.

- Step 10: Secure Load After Lift Completion

Secure the load to a stable anchor point before moving on to the next task (ASME B30.5-2020 section 3.13). Make sure it's properly tied off with adequate rigging and support.

- Step 11: Document Findings

Document all inspections, notes, and results in your certification logbook or inspection report (ASME B30.5-2020 section 6). This will serve as proof of compliance for future OSHA audits.

- Step 12: Regularly Maintain Equipment

Regularly inspect, maintain, and perform necessary repairs on your crane equipment (ASME B30.5-2020 section 2.3). Stay up-to-date with industry standards to avoid any potential liabilities.

- Step 13: Continuously Update Training and Knowledge

Participate in regular training sessions, workshops, or online courses to improve your skills and knowledge on crane operation (ASME B30.5-2020 section 3.16). Stay current with OSHA regulations and guidelines.

- Step 14: Follow Regulatory Requirements

Familiarize yourself with relevant safety standards, OSHA guidelines, and local laws that govern your crane operations (ASME B30.5-2020 section 1). Ensure compliance throughout all phases of operation.

Following these steps will ensure safe and efficient crane operation on the job site. Remember to stay vigilant, follow established procedures, and keep detailed records for future reference.

Critical Mistakes That Fail Operators on Exams and Job Sites

You're about to become a certified crane operator. You've spent years learning the ropes, but without attention to detail, you'll be stuck in neutral for good. Here's what not to do:

1. Don't assume you know it all - failing OSHA standards can cost you your job and even lead to fatalities.

- Maintaining a load line at the correct height is crucial, but some operators overlook this step because they're too focused on lifting heavy loads.

- Check your boom's swing radius before swinging it around - underestimating this can result in lost control and costly repairs.

These mistakes are like a ticking time bomb, waiting to take down even the most experienced operators. The numbers speak for themselves: OSHA reports that crane-related accidents cost employers $140 million annually. That's not just money; it's lives.

Forgetting Safety Protocols Can Be Deadly

You've spent years studying and practicing your skills, but if you're not paying attention to safety protocols, all of that goes for naught. According to the National Institute for Occupational Safety and Health (NIOSH), crane operators are more likely than other construction workers to die on the job.

For example, in 2020 alone, there were 116 reported crane-related fatalities across the United States.

Miscalculating Load Charts Can Lead to Failure

Load charts aren't just for show; they're a critical part of ensuring safe crane operations. If you miscalculate or misinterpret these charts, you risk losing control of your load.

According to the American Society of Mechanical Engineers (ASME), improper use of load charts can result in equipment failure and damage.

- Failing to perform regular inspections on your crane's systems is like playing a game of " roulette" - you never know when disaster will strike.

- Using the wrong type of wire rope for the job can lead to catastrophic failures, putting yourself and others at risk. becoming a certified crane operator requires attention to detail and a commitment to safety protocols. Don't make these costly mistakes - learn from them before it's too late.

Remember: OSHA regulations are in place to protect you and your coworkers. Stay on top of your game and always follow the rules.

OSHA and ASME Compliance Requirements

You're about to learn how to navigate the complex world of OSHA regulations for crane operators. With 20+ years of field experience under your belt, you know that staying compliant is crucial for a safe job site.

The Occupational Safety and Health Administration (OSHA) sets standards for general industry, maritime, gear certification, and construction. Specifically, section 1926.1400 covers crane operators' duties, requirements, and regulations.

General Crane Operator Requirements

- Understand the load line and swing radius of your crane

- Gather equipment and tools as required by the job

- Inspect the crane and its components regularly for damage or wear

ASME B30.5, which covers overhauling and repairing overhead cranes, derricks, hoists, winches, and monorails, also outlines specific requirements for operators.

Regular Inspections

The frequency of inspections depends on the crane's age, usage, and condition. According to OSHA, you should:

- Every 6 months: Perform a visual inspection of the crane's exterior and interior components.

- After each use: Check for damage or wear on the load line, swing radius, and boom

- Before operating: Verify that all systems are functioning properly and that the crane is properly positioned on firm ground with outriggers fully extended.

Documented Findings and Penalties

If you fail to comply with OSHA regulations, you risk fines ranging from $5,000 to $70,000 per violation. Additionally, repeat offenders may face penalties of up to $136,500.

- Keep a logbook or report all inspection findings and any repairs made

- Document the date and time of each inspection

- Store records for at least 3 years

Recent Regulatory Changes

In 2025, OSHA updated its crane operator training requirements to include more comprehensive training programs. The new guidelines cover topics such as:

- Load line and swing radius calculations

- Boom and outrigger positioning techniques

- Wire rope inspection methods

Additionally, the 2026 budget for Fort Worth council included a tax rate reduction and increased service fees for homeowners. Meanwhile, construction workers can expect to see an average crane operator salary of $93,000 per year in Illinois.

Finding Resources

For more information on OSHA regulations and ASME standards, visit:

- Osha.gov

- American Society of Mechanical Engineers (ASME) website

How Crane Operator Salary Guide Appears on Your NCCCO Certification Exam

You've worked hard to become a certified crane operator, and now you're ready to take the next step in your career. Understanding how much you'll earn as a crane operator is crucial for planning your future. Let's break down what you can expect on your exam.

Question Formats

The NCCCO certification exam includes various question formats, including multiple-choice scenarios and calculations. Be prepared to answer questions that test your knowledge of crane operations, safety procedures, and regulations.

- Multiple-Choice Scenarios: You'll be presented with hypothetical situations involving crane operations. Choose the correct course of action based on industry standards and best practices.

- Calculations: Be able to calculate load weights, boom angles, and swing radii. These calculations will help you determine safe operating distances and load configurations.

Frequently tested concepts include load charts, crane capacity, rigging methods, and safety protocols. Study these topics thoroughly to increase your chances of passing the exam.

- Load Chart Interpretation: Understand how to read and create load charts for different types of loads and boom configurations.

- Crane Capacity: Know the maximum weight capacity of various cranes, including overhead cranes, tower cranes, and mobile cranes.

Example Exam-Style Questions

Here are a few examples of exam-style questions to help you prepare:

The answer requires calculations based on the crane's capacity, boom length, and swing radius. Use industry standards to determine the safe load weight.

The correct answer requires knowledge of rigging methods and safety protocols. Choose the safest option based on industry best practices.

Practice Tests and Pass Rates

CCO Exam Prep offers over 515 practice questions covering this topic for $74.95, with a money-back guarantee. These practice tests will help you identify areas where you need improvement and increase your chances of passing the exam.

- Practice Tests: Complete as many practice tests as possible to simulate the actual exam experience.

- Identify Weaknesses: Review questions that give you trouble to focus on areas where you need improvement.

By studying and practicing with CCO Exam Prep, you'll be well-prepared for your crane operator salary guide section of the NCCCO certification exam. Stay focused, and good luck!

Real-World Application and Expert Tips

You're a crane operator with years of experience, but have you ever stopped to think about your earning potential? The truth is, salaries can vary significantly depending on the state you work in. Let's take a look at some numbers from the Crane Operator Salary Guide 2025-2026.

State-by-State Earnings

According to Google News, the average annual salary for crane operators in the United States is around $93,000. However, salaries can range from around $40,000 in some states to over $150,000 in others. Let's take a closer look at some of the top-paying states:

- California: $124,000 per year

- Alaska: $116,000 per year

- Washington: $113,000 per year

- New Jersey: $109,000 per year

- Connecticut: $106,000 per year

Roughly 50% of crane operators make between $60,000 and $90,000 annually. However, those who work in the top-paying states can expect to earn significantly more.

Career Advancement Opportunities

While a typical crane operator's career path may involve working as an entry-level operator for 5-10 years before moving into a foreman or supervisor role, there are opportunities for advancement beyond that. According to Jackson Lewis, employers in Illinois can expect to see essential updates on employment law in 2025.

Some crane operators also choose to pursue specialized certifications or training programs to advance their careers. According to CCO Exam Prep, the platform has helped thousands of operators pass their certification exams and achieve success in their careers.

Pro Tips from Experienced Operators

Here are a few pro tips from experienced crane operators that can help you increase your earning potential:

- Tip 1: Stay organized - Keep track of your certifications, training programs, and any other relevant documents to stay competitive in the job market.

- Tip 2: Network - Attend industry events and conferences to meet other operators and learn about new opportunities.

- Tip 3: Stay up-to-date on regulations - Familiarize yourself with OSHA standards and any other relevant regulations to ensure you're working safely and efficiently.

Rigging, boom, load line, outriggers, swing radius – as a crane operator, it's essential to stay on top of your game. With the right certifications, training, and experience, you can increase your earning potential and achieve success in your career.

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test