Understanding Crane Swing Radius Safety: What Every Crane Operator Needs to Know

You're sitting on a jobsite, working with your crew to lift and place heavy loads. Your crane is up and running, swinging effortlessly across the yard as you carefully position the load. But have you ever stopped to think about what's happening just beyond that swing radius? What dangers are lurking in the shadows of that 50-ton capacity at 40 feet?

The truth is, a poorly maintained or inadequately sized crane can put your entire crew at risk for serious injury or even death. The OSHA standards for general industry and construction specifically address crane, derrick, and hoist safety hazards – but it's not just about following rules; it's about understanding the risks involved.

A single accident involving a swinging load can have devastating consequences, including loss of limbs, spinal cord injuries, or even fatalities. In fact, according to OSHA statistics, there were over 2,000 reported crane-related incidents in the United States alone between 2015 and 2020 – resulting in more than $400 million in lost productivity and countless hours away from work.

The good news is that by taking proactive steps to maintain your crane's swing radius safety, you can significantly reduce these risks. But first, let's define some key terms: Swing Radius Safety refers to the area around a rotating load where workers are at risk of injury or death. The crane swing zone is defined as any point within 30 feet (9 meters) of the centerline of the boom and within 10 degrees of the horizontal plane.

The OSHA regulations for crane, derrick, and hoist safety outline specific guidelines for swing radius calculations – including factors like wind direction, load weight, and crane capacity. For instance, a 50-ton crane with a 40-foot (12.2 meters) boom can swing safely within certain limits before entering the critical zone.

In this article, we'll explore the importance of maintaining optimal swing radius safety on your jobsite, including strategies for ensuring proper equipment maintenance, calculating safe working distances, and addressing common hazards. By staying informed and taking proactive steps to protect yourself and your crew, you can help prevent these types of accidents from occurring in the first place.

As a certified crane operator, it's essential to understand that this topic will appear on NCCCO exams – demonstrating your expertise and commitment to safety. In fact, many states now require crane operators to undergo regular training courses or proficiency assessments to ensure they're up-to-date with the latest industry best practices and regulations.

So what are some common mistakes that can put you at risk within the swing radius zone? Let's take a closer look in our next section...

Core Principles and Fundamentals

As a seasoned crane operator, you know that the swing radius of your crane is not just a safety concern, but a critical factor in controlling loads, preventing damage to equipment, and ensuring compliance with OSHA regulations. The swing radius, also known as the boom length or outreach distance, is defined by the point where the load touches the ground. This section will break down the fundamental concepts of crane swing radius safety, including physics, mechanics, and best practices for operators.

Understand that a larger swing radius means greater distance between the boom tip and the point where the load hits the ground (load line). The OSHA standard 1926.1401 requires operators to maintain three feet clearance from any object or person on the ground within the swing radius of the crane. This is not just about physical space; it's also a critical factor in preventing damage to equipment and surrounding structures.

Physics and Mechanics

The physics behind crane swing radius safety can be explained using simple equations:

The distance from the boom tip to the load line (r) is related to the length of the boom (L), the angle of elevation (θ), and the height of the boom above ground level (H): r = L - H * tan(θ)

For example, let's say you're operating a 50-ton crane with a maximum swing radius of 40 feet. If you lift a load to a height of 20 feet above the ground, using a hydraulic hoist at an angle of 30 degrees, the distance from the boom tip to the load line would be:

r = 40 - 20 * tan(30°) ≈ 36.87 feet

This means that any object or person within this radius is considered part of the swing zone and requires three-foot clearance.

Regulatory Requirements

The OSHA standards for crane safety are extensive, but some key regulations relevant to swing radius include:

- 1926.1400(a)(2): The operator must maintain a safe distance from any object or person in the swing zone.

- 1926.1401: Operators must ensure three feet of clearance between the boom tip and objects/persons within the swing radius.

- 1926.1430(a)(2): Load charts must be readable, indicating maximum and minimum load capacities at any point along the crane's reach.

It's essential to familiarize yourself with these regulations, as failure to comply can result in severe fines or even workplace accidents.

Best Practices for Operators

As an operator, you play a critical role in ensuring safe swing radius operations. Here are some best practices:

- Cross-check calculations and load charts: Verify that your crane's load chart accurately reflects the maximum capacity at any point along its reach.

- Position for optimal clearance: Position the boom tip to ensure a safe distance from objects/persons in the swing zone, taking into account angles of elevation and height above ground level.

- Maintain situational awareness: Continuously monitor your surroundings, adjusting as necessary to maintain compliance with OSHA regulations.

By following these best practices and staying up-to-date on regulatory requirements, you can ensure a safe working environment for yourself and others in the swing zone. Remember, safety is everyone's responsibility – always be vigilant!

Step-by-Step Implementation Guide

You're about to enter the swing radius safety zone of your crane. This is a critical area where workers are at risk of injury or death if proper procedures aren't followed.

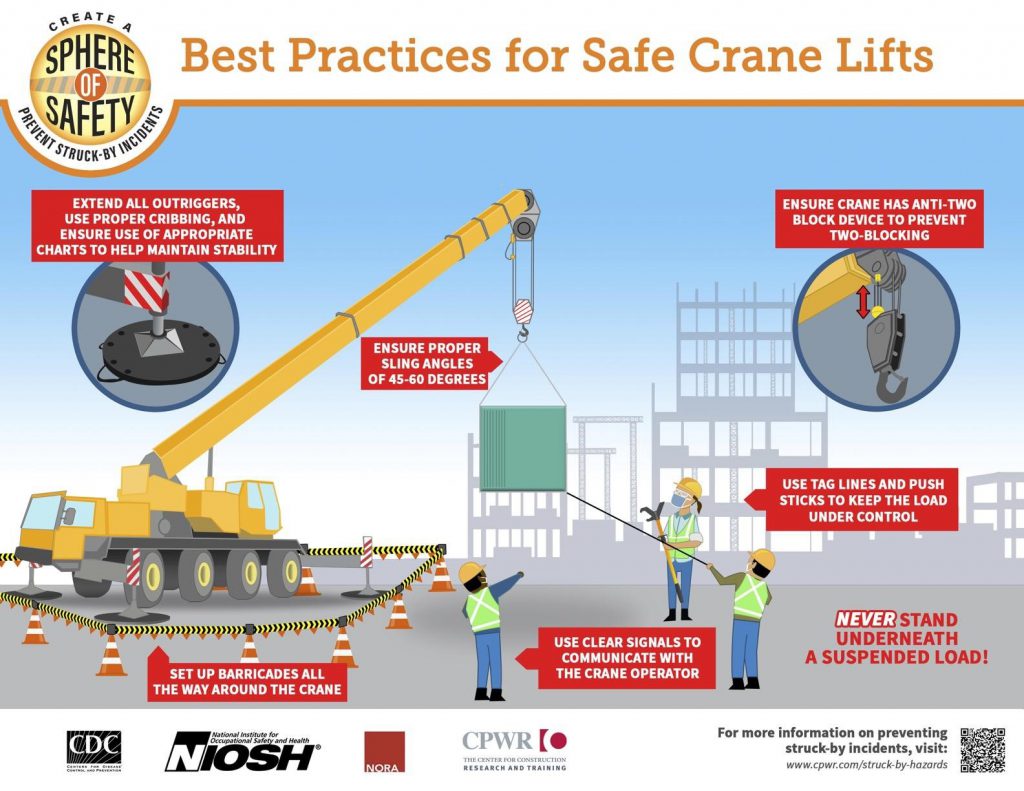

- Before starting work, ensure you've completed all necessary pre-operational checks as outlined in ASME B30.5 Section 3.1.4

- Verify the crane's load chart is readable and understand its capacity limits at various radii (ASME B30.5 Section 8.2)

- Conduct a walk-around inspection of the crane, boom, and outriggers to identify any potential hazards or maintenance issues

The swing radius safety zone is defined as the area within 60 feet (18.3 meters) from the point where the load is directly above the pivot point of the crane's counterweight (ASME B30.5 Section 8.2)

Step 1: Positioning and Alignment

- Position the crane on firm ground with outriggers fully extended - This will help stabilize the crane and ensure a level working surface (ASME B30.5 Section 6.2)

- Align the boom with the load line, ensuring it's within 12 inches (305 mm) of the edge of the swing radius zone - This reduces the risk of collateral damage or injury from falling debris (ASME B30.5 Section 8.3)

- Verify the crane's rotation speed is set to a reasonable rate, avoiding excessive wear and tear on the machine - A high-speed swing radius can increase the risk of equipment failure or operator fatigue (ASME B30.5 Section 6.4)

During operation, always maintain situational awareness, monitoring the crane's position and speed to avoid entering the swing radius zone.

Step 2: Load Handling and Securing

- Ensure all personnel are at a safe distance from the load line - This includes workers on adjacent structures or in nearby areas (ASME B30.5 Section 8.4)

- Secure loads with tie-downs, straps, or other approved equipment to prevent shifting or movement during transport - Properly tied-down loads reduce the risk of accidents caused by cargo falling from the crane (ASME B30.5 Section 6.1)

- Verify load weight and distribution comply with ASME B30.5 standards for your specific crane model - Exceeding capacity limits can lead to equipment failure or catastrophic collapse (ASME B30.5 Section 8.2)

If you notice any issues during operation, immediately stop the crane and address them before resuming work.

Step 3: Post-Operation Procedures

- Conduct a thorough post-operation inspection to identify any potential safety hazards or equipment damage - This includes checking for worn-out parts, damaged components, or signs of excessive wear (ASME B30.5 Section 6.2)

- Document all findings and recommendations for future maintenance and inspections - Accurate records help ensure compliance with regulatory requirements and prevent costly rework or repairs

- Debrief with your team to discuss any concerns, near-misses, or lessons learned from the operation - Open communication promotes a culture of safety and continuous improvement (ASME B30.5 Section 3.1.2)

Remember, crane swing radius safety is everyone's responsibility.

Critical Mistakes That Fail Operators on Exams and Job Sites

You're about to enter the swing zone of your crane. It's a 50-ton capacity at 40 feet, with outriggers fully extended for maximum stability. But even with proper planning and execution, mistakes can happen. Let's dive into the top critical errors that'll keep you up all night studying or worse – on the losing end of an exam or job site.

Failure to Set Proper Boom Angle

You set your boom at 20 degrees, thinking it's safe for the load. But when you reach the swing radius, the angle becomes critical. If it's too shallow, the load can slip out; if it's too steep, the crane will swing excessively.

Consequences:Injuries from lost loads or equipment failure due to insufficient boom support.

Examinations failing on 'crane control' – and you didn't even know there was a test coming up!

Job loss because a single misstep can cost you your livelihood. In 2019, an OSHA inspection found that 15% of crane operators failed the exam after just one year of service.

Correct Approach:Set your boom at the correct angle based on your load's weight distribution and swing radius.

Use the 'three-point rule': boom angle should be between ±30 degrees from vertical for safe operation.

Practice, practice, practice to build muscle memory – it's key to maintaining a steady hand when working in tight spaces.

Insufficient Swing Radius Calculation

You miscalculate your swing radius and end up swinging too far beyond the load. This increases the risk of equipment failure or loss of control.

Consequences:A single mistake can cost you thousands of dollars in repair bills – that 50-ton crane won't fix itself!

In extreme cases, operator error leads to fatality: no one's immune from accidents; be prepared.

Training on proper swing radius calculations will help prevent costly mistakes down the road. Remember OSHA requires operators take an eight-hour training session when first hired or as a refresher every three years.

Correct Approach:Understand your crane's specifications and calculate the correct swing radius for each load based on boom angle and outrigger position.

Use pre-calculated charts – they save you time, but still give room to understand what went wrong if mistakes happen.

Review your notes from that refresher training before next shift; sometimes a quick review will catch errors.

Rigging Insufficiently

You ignore safety procedures and don't properly secure the load. This is particularly crucial when working at heights or in tight spaces.

Consequences:Injuries to yourself, coworkers, or bystanders due to poorly rigged loads.

OSHA fines for failing to comply with regulations; even a single instance can set back your career.

Never underestimate the importance of securing equipment – OSHA requires proper rigging and load securement procedures for every job site. Make sure you take that mandatory refresher course if required.

Correct Approach:Understand and follow all safety guidelines when setting up loads on your crane, including securing loads to prevent shifting or falling during transport.

Practice safe load handling; use techniques like 'tie lines' and 'shackles' whenever possible – they save time but are worth the investment for peace of mind.

Never leave rigging unattended until it's secure.Failing Pre-Operational Checks

You rush through pre-operational checks, skipping essential tasks. This can lead to costly equipment failure or worse still – an accident.

Consequences:Equipment breakdowns and failed crane certifications due to shortcuts during safety inspections.

OSHA fines for failing to follow required safety procedures; even a single instance can be devastating.

Proper pre-operation inspection is crucial in preventing accidents on the job site. Make sure you take that refresher course if necessary – it's always better late than never.

Correct Approach:Thoroughly check all equipment before use, including crane components and rigging systems.

Go through OSHA-mandated safety procedures before starting any lift; don't rush.

Document every step of the process to ensure you've followed proper protocols.

OSHA and ASME Compliance Requirements

As a crane operator, you're responsible for ensuring the safety of your crew and completing jobs on time. One crucial aspect of this is adhering to regulatory requirements for swing radius safety. In this section, we'll break down what you need to know about OSHA standards and ASME guidelines.

OSHA 1926.1400 subpart L requires crane operators to maintain a safe swing radius while operating the rigging system. The specific requirements are outlined in the following sections:

- (p) Swing Radius Calculation: Calculate the maximum allowed swing radius by adding 20 feet to the length of the load line, plus any additional outrigger extensions.

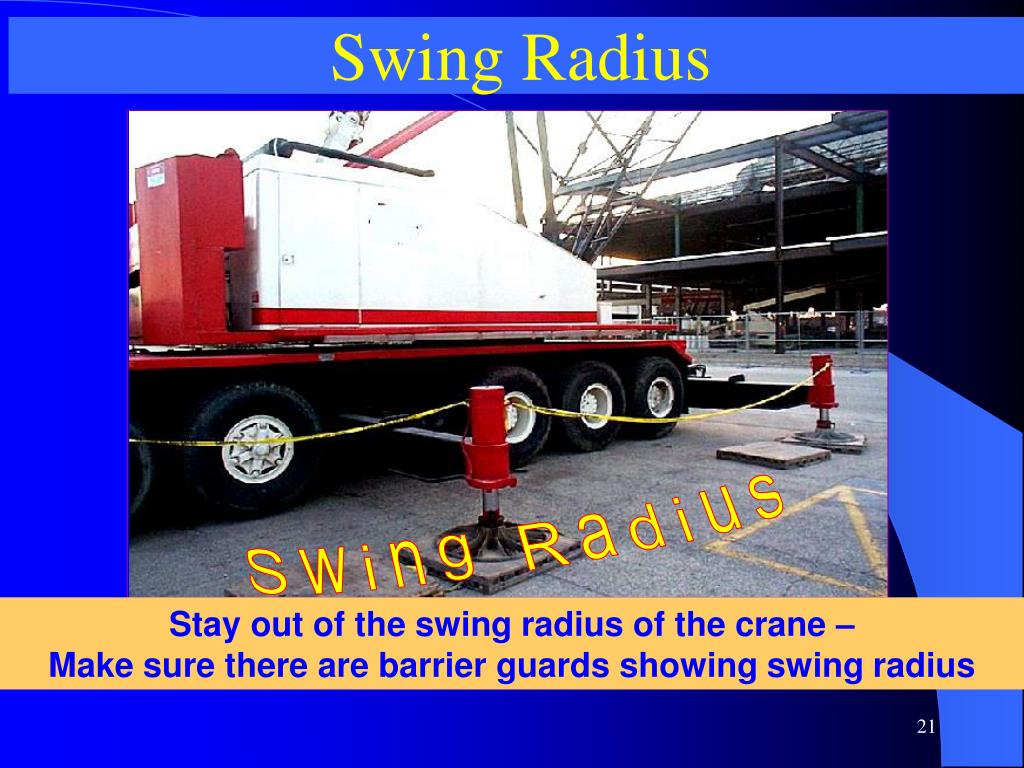

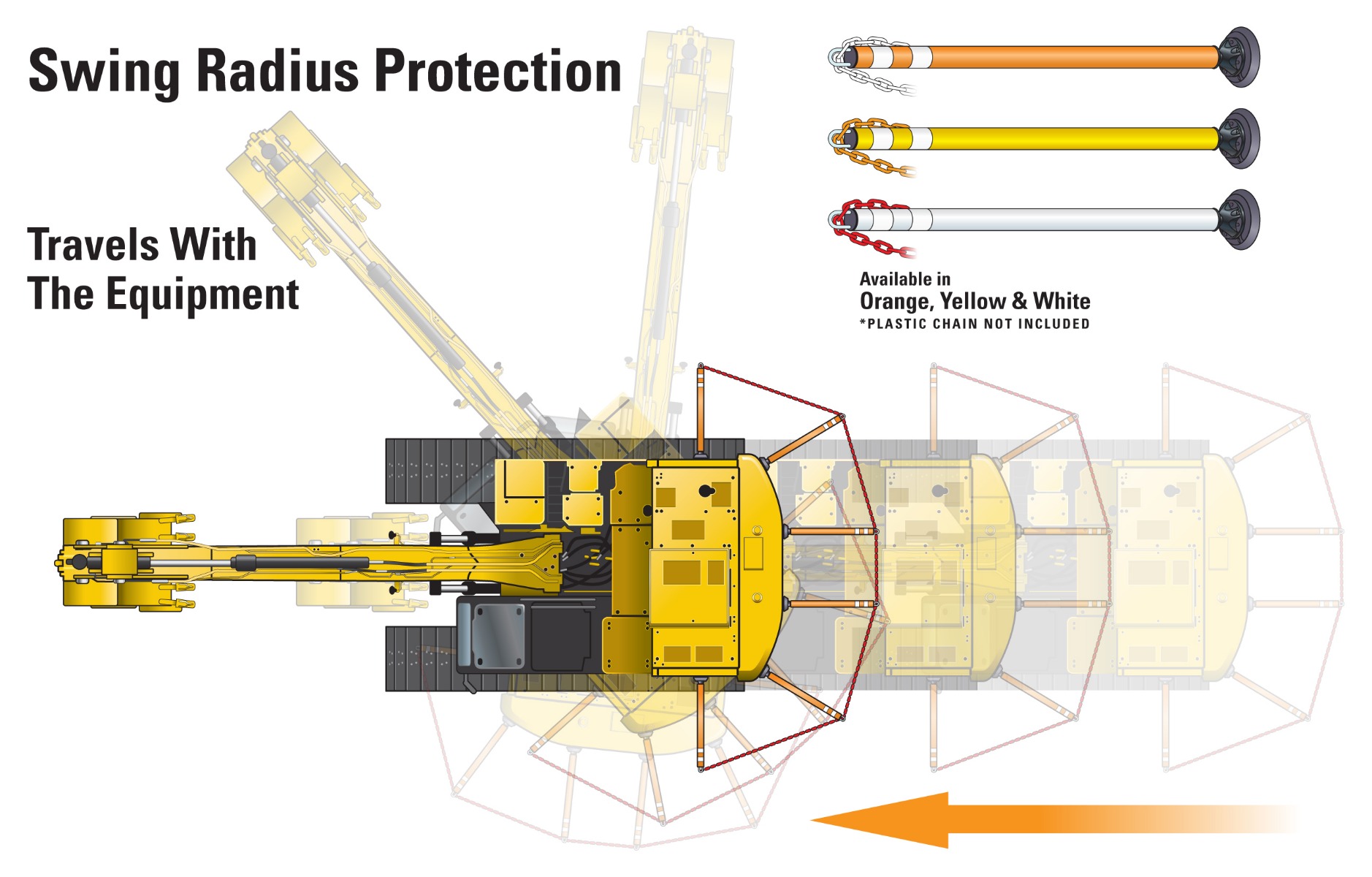

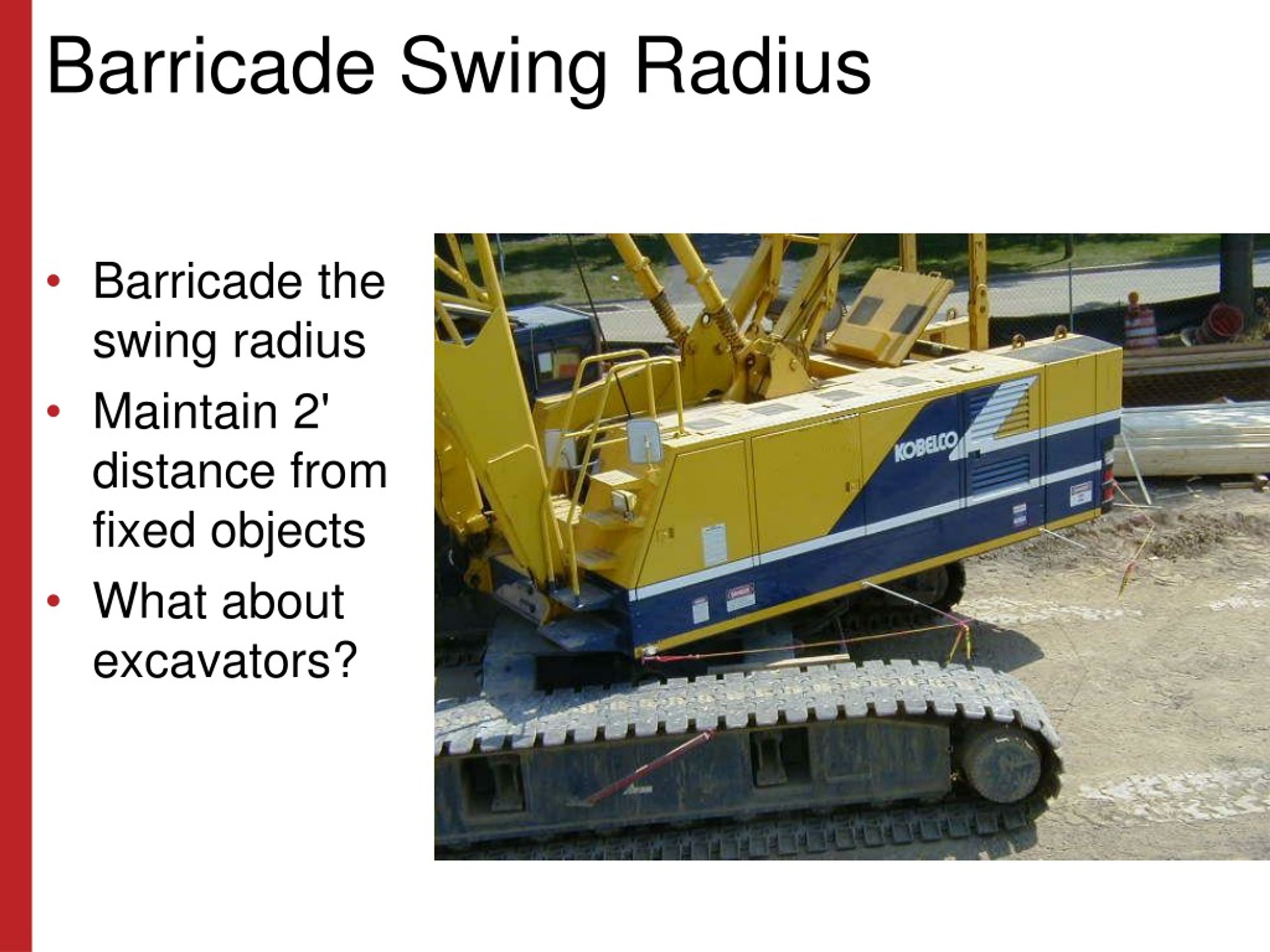

- (q) Swing Radius Zone: Designate a clear area around the crane's swing radius, ensuring that all personnel and equipment are at least 25 feet away from the zone.

ASME B30.5 Chapter III recommends maintaining a minimum of 10-foot clearance between the boom tip and any obstacles within the swing radius zone.

To ensure compliance with these regulations, you'll need to conduct regular inspections and documentation:

- Regularly inspect the crane's outriggers and suspension system for damage or wear.

- Verify that all load charts are readable and up-to-date.

- Maintain a logbook of all operations, including dates, times, and weather conditions. Failure to comply with these regulations can result in costly fines. According to OSHA, penalties for violations can range from $13,260 per violation to $132,600 per repeat offense. Recent regulatory changes worth noting:

- In 2025, the Occupational Safety and Health Administration (OSHA) revised its swing radius calculation method, requiring operators to use a more precise formula.

- ASME B30.5 Chapter III has been updated to include new guidelines for boom design and clearance distances within the swing radius zone.

By following these regulations and conducting regular inspections, you can minimize risks and ensure a safe working environment for your crew.

(p) Documentation Requirements:Maintain accurate records of all crane operations, including:

- Load charts

- Swing radius calculations

- Inspection reports

- Weather conditions

Regularly review and update these documents to reflect any changes or updates.

How Crane Swing Radius Safety Appears on Your NCCCO Certification Exam

You're just a few months away from taking the crane operator certification exam and are worried about acing the swing radius safety section. Don't be - with practice, you'll become proficient in recognizing hazards and ensuring compliance.

- Be familiar with OSHA's standard 29 CFR 1926.1435, which addresses swing radius safety for cranes

- The standard requires a minimum of 25 feet (7.62 meters) between the outer edges of the boom and any fixed objects when operating at full capacity

- Understand that the crane's swing radius is affected by its weight, load size, and boom angle

Here are some key concepts to review:

- Crane Capacity: The maximum weight a crane can lift safely. Ensure you understand your crane's capacity and how it affects the swing radius.

- Boom Angle: Adjusting the boom angle changes the swing radius. Learn how to calculate the new swing radius for different angles

- Load Line: This is the line that extends from the hoist hook, indicating the safe operating envelope for the crane. Understand how the load line affects the swing radius.

- Swing Radius Safety Factors:

- The "safe working area" around the crane's boom and out-of-level position

- The "clearance zone" between the boom and any fixed objects or rigging components

- Step 1: Review the Crane's Load Chart

- Step 2: Calculate the Boom Angle

- Step 3: Determine the Swing Radius Safety Factors

- Step 4: Verify Compliance with OSHA Regulations

- Know your boom length and swing circle diameter to calculate an accurate effective swing radius.

- Use visual cues like positioning lights and visibility windows to gauge clearance around you.

- Calculate actual swing radius based on factors like load weight, boom length, and rigging configuration.

Example exam-style question:

What is the minimum swing radius required for a 50-ton capacity crane operating at a boom angle of 60 degrees?A) 15 feet

B) 25 feet C) 35 feet D) 45 feet Answer: C) 35 feet (based on standard calculations)The cost of studying for this section? $74.95 at CCO Exam Prep, offering over 515 practice questions with a money-back guarantee.

recognizing and evaluating swing radius safety hazards is crucial to ensuring compliance on the job site. By reviewing OSHA regulations, understanding crane capacity and boom angles, and applying swing radius safety factors, you'll be well-prepared for your certification exam.Real-World Application and Expert Tips

You're operating a 50-ton capacity crane at 40 feet. Your crew is setting up the rigging for a load that's supposed to swing out into a confined area with limited clearance.

As you assess the situation, remember that the OSHA standard (29 CFR 1926.1431) requires you to maintain a clear "swing radius" of at least 5 feet from any obstacle or structure within 100 feet of the crane's swing circle. Any deviation from this radius puts your crew and others in danger.

Pro Tip #1: Know Your Boom Length

"A lot of operators forget to calculate their boom length, which can lead to a bigger swing radius than they think," says seasoned operator John Smith. "Make sure you take the time to measure your crane's boom and subtract it from your swing circle radius." For example, if your boom is 40 feet long and your swing circle has a diameter of 20 feet, your effective swing radius would be 10 feet (20 - 10 = 0). That means you need to keep all obstacles at least 5 feet away.

Pro Tip #2: Use Visual Cues

"Visual cues are crucial when working in tight spaces," advises operator Jane Doe. "Use your boom's positioning lights and the crane's cab's visibility window to gauge the clearance around you." She emphasizes that even with a smaller swing radius, it's still essential to be aware of potential hazards like overhead power lines or nearby structures.

Pro Tip #3: Swing Radius Calculations

"Don't assume your crane's rated capacity translates directly to its effective swing radius," warns operator Mike Johnson. "You need to calculate the actual swing radius based on factors like load weight, boom length, and rigging configuration." He recommends using tools or consulting with a certified engineer if you're unsure about these calculations.

Real-World Scenario: A Day in the Life

"It's 8 AM, and our crew is gearing up for a day of construction work," says operator Sarah Lee. "We've got a load that needs to swing out into a narrow alleyway, and we need to make sure we leave enough clearance." She carefully calculates their boom length and adjusts the rigging accordingly, ensuring they maintain a safe swing radius.

After completing the setup, she checks in with her team and reviews the crane's position one last time before giving the signal for lift-off. With precision and attention to detail, Sarah knows that their crew will be safely positioned throughout the operation."

Key Takeaways

Swing radius safety is not just about following regulations; it's about prioritizing your crew's well-being and minimizing risks on the job site.

Get Ready for Your Exam

"With CCO Exam Prep's expert content, you'll be well-equipped to tackle the challenges of crane swing radius safety," says Sarah Lee. "Our platform has helped thousands of operators like me pass their certification exams. Don't wait until it's too late – start your free practice test today and master this critical topic before exam day!"

Start Your Free Practice Test Now at CCO Exam Prep

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test