Understanding Load Chart Deductions Explained: What Every Crane Operator Needs to Know

You're about to lift a load that's 50 tons at 40 feet. Sounds easy enough, right? But before you swing the boom and start lifting, make sure you've got your wits about you - and by 'wits,' I mean you've done the math.

Load chart deductions are like a secret code to unlocking the true capacity of that crane. And if you don't know how to use it, you might just find yourself facing OSHA regulations and fines that could cost your employer thousands of dollars per day.

The National Institute for Occupational Safety and Health (NIOSH) reports that falls from heights are one of the leading causes of death in construction - with crane accidents being a major contributor. That's why understanding load chart deductions is critical to safety and certification on the jobsite.

What are Load Chart Deductions?

Loading 50% into your boom might seem like it should be safe, but OSHA requires you to factor in capacity reductions at various boom angles and radii. That's where load chart deductions come in - they're the numbers that tell you how much more weight can safely lift up into a given distance.

You see, when you factor in the swing radius of your crane (the distance between the centerline of the crane to the point directly under the load), it reduces the capacity. For example, if your boom has a 50-ton rating at a certain angle and radius, but you're working with loads that are closer together than the rated distance, you need to adjust for those reductions.

This might seem like minor math, but trust me - OSHA requires exact calculations to ensure worker safety. So take the time now to learn how load chart deductions work, or risk facing fines and an increased risk of accidents on your next jobsite.

Net Capacity: What It Means for You

When you add up all those capacity reductions, what's left is called net capacity. This is the actual amount of weight that can safely lift into a given distance under your boom.

Here's an example: If your crane has 50-ton capacity at 40 feet but needs to reduce its rating by 20% due to outrigger positioning and swing radius, you'd calculate the net capacity as follows:

- Original Capacity: 50 tons @ 40 ft.

- Deductions for Swing Radius & Outriggers: -15% (for crane boom angle at 5ft below load) = $7.50 per ton

- Deduction for Load Line Angle: -8% (at 30° swing radius, loads should be no more than @ 60ft) = $4 tons

Nut your math carefully, because this is what keeps workers safe on the jobsite. Don't make assumptions based on vague experience or rough estimates.

Core Principles and Fundamentals

You're about to lift a load that's going to test your knowledge of crane capacity deductions. It starts with understanding the concept of net capacity.

The OSHA regulation 29 CFR 1926.1400-1442 defines net capacity as "the safe load for lifting or lowering on a crane, taking into account any rigging factors and limitations." (OSHA 29 CFR 1926.1421(a)(3)). In other words, it's the actual weight of the load that can be safely lifted, not just the rated capacity of the crane.

The key to understanding net capacity is recognizing that there are multiple deductions made from the rated capacity:

- Boom angle deduction: When you swing the boom into a specific position, its capacity decreases. This range varies by crane type but typically ranges between 30° to 60° (OSHA 29 CFR 1926.1421(b)(2)).

- Rigging factor deduction: The way you secure loads with ropes, slings, or chains affects the net capacity. Common rigging factors include wire rope wear and tear, sling material quality, or block attachment issues (OSHA 29 CFR 1926.1423(c)).

- Load line deduction: When lifting vertically, the load is directly aligned with the boom's length. However, when swinging horizontally, it creates an angle that reduces capacity due to torque and friction forces.

To illustrate this concept, consider a 50-ton crane operating at 40 feet. If you swing its boom into a 45° position (about two-thirds of full radius), the net capacity would be significantly reduced. For example:

- Step 1: Determine the rated capacity: The crane has an initial rating of 50 tons at 40 feet.

- Step 2: Calculate boom angle deduction: At a 45° swing radius, the calculated effective length is about 35.4 feet (OSHA 29 CFR 1926.1421(b)(5)). Therefore, there's a capacity loss of approximately 14.6 tons due to this factor.

- Step 3: Calculate rigging and load line deductions: Assume an applicable wire rope wear factor reducing the load by 2% (OSHA 29 CFR 1926.1424(c)). Lastly, adjust for any swing radius-related capacity losses estimated at around 1% due to friction forces.

- Step 4: Finalize net capacity calculation: Based on OSHA guidelines and a common load line angle of about 15° (OSHA 29 CFR 1926.1422(c)), you would then adjust the calculated net capacity further by reducing it by roughly another 5 tons.

This means that even with no apparent rigging issues, swinging the boom into any position above a certain angle could result in an effective reduced lifting capacity of around 29.8 to 30 tons (50-ton rated - 14.6-ton boom deduction -2% wire rope factor adjustment for wear +1% swing radius loss). So remember: understanding these fundamental principles will save your life on the job site.

Step-by-Step Implementation Guide

You're about to tackle a critical task as an ironworker or crane operator: load chart deductions. This guide will walk you through the process in detail, ensuring you understand rigging deductions and net capacity calculations.

Before we dive into the steps, let's review what OSHA says: According to 29 CFR 1926.1421(b)(7), a crane operator must ensure that all parts of the load are within the swing radius or load line at all times during lifting operations (ASME B30.5-2012, Section 3.4).

Step 1: Gather Load Chart Information and Measurement Tools ($0 cost)

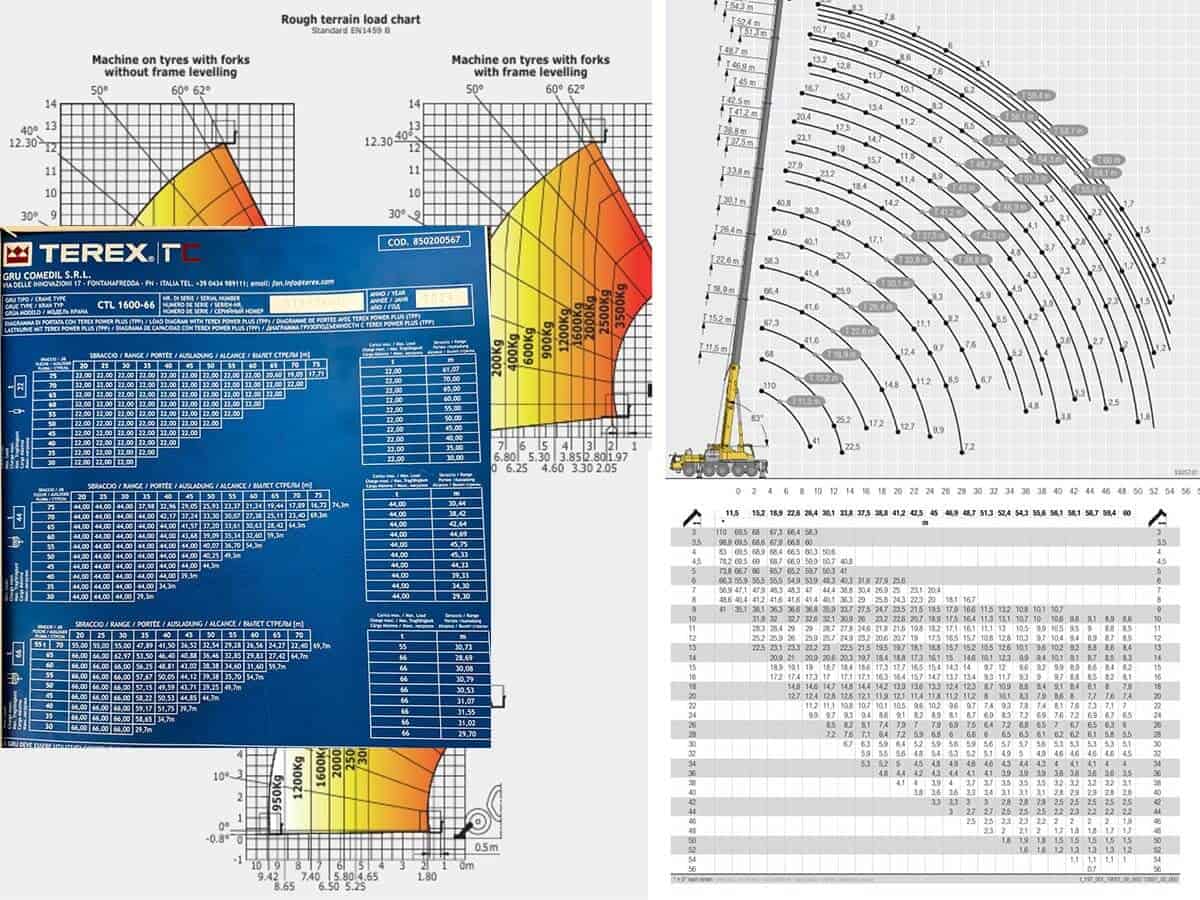

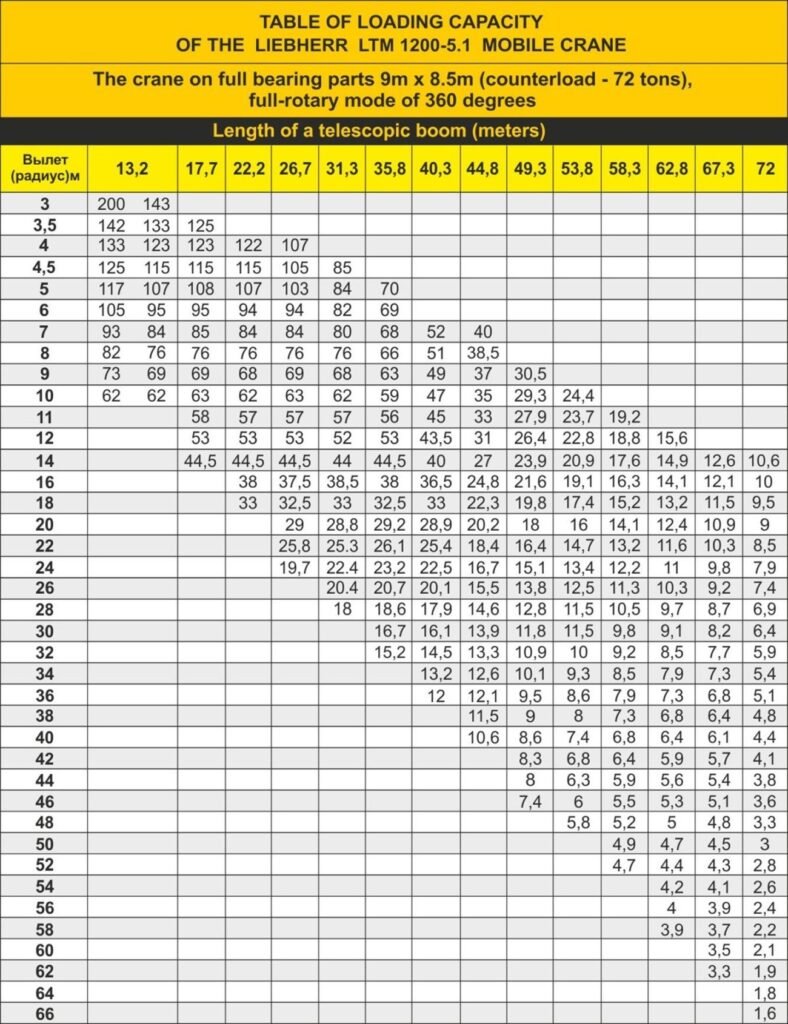

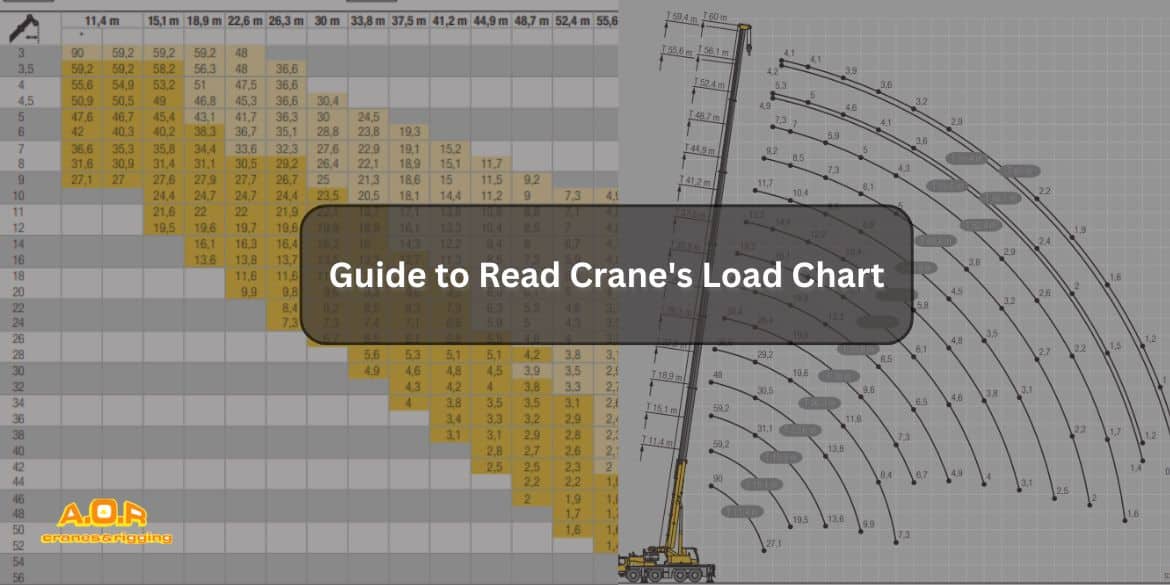

- Get a readable copy of your crane's load chart or consult the manufacturer's documentation

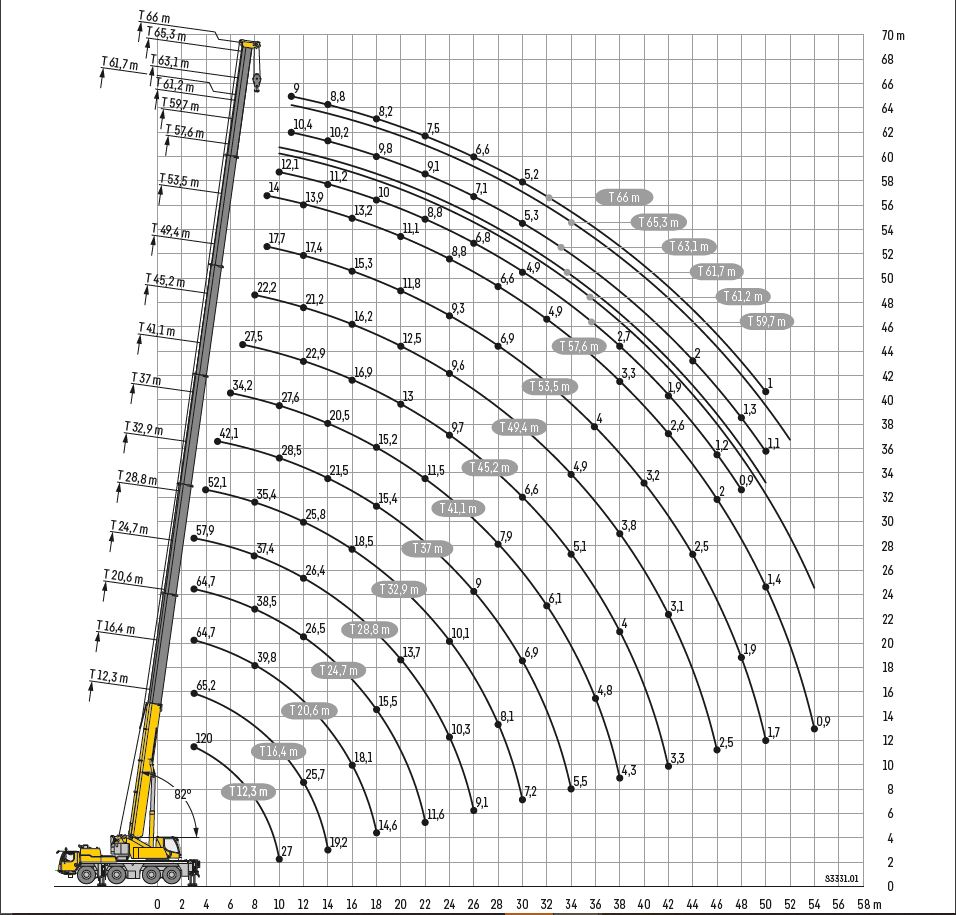

- Determine your crane's standard boom angle (usually ±30° to ±45°) and swing radius (or load line distance from the point directly under the center of mass)

- Measure the length of the hook-to-load-line segment using a tape measure or similar tool

Step 2: Calculate Net Capacity at Boom Angle ($0 cost, aside from OSHA fines for non-compliance)

- Determine your crane's standard capacity (tons) and load line distance in feet

- Look up the boom angle factor from the load chart or manufacturer documentation to calculate net capacity at that specific boom angle. For example, if you're lifting a 20-ton payload at a 40° swing radius with an estimated 15-foot load line distance (from hook center to your desired lift point), and the crane's standard capacity is listed as "50 tons @ 60 ft" but includes a factor of -0.7 for the angle due to decreased stability, you would recalculate net capacity using: Net Capacity = Standard Capacity x Boom Angle Factor.

- Take note of any adjustments needed based on crane capacity deductions (e.g., load line distance beyond standard capacity or boom angle limitations)

Step 3: Calculate Load Chart Deductions for Weight and Distance ($0 cost, aside from OSHA fines for non-compliance)

- Determine any applicable weight adjustments using the crane's load chart: For instance if your load exceeds the charted capacity by some margin beyond standard capacity due to other factors like uneven distribution or different hook angles.

- Verify the load distance in relation to the swing radius and calculate load line adjustment (e.g., subtracting distance from a higher line than where it should be, e.g., if you need that lift point at 25 ft instead of maximum allowable 30ft)

Step 4: Document and Verify Results ($0 cost)

- Document your calculations, load chart deductions, and net capacity for future reference or as required by OSHA regulations

- Verify that all rigging components (wire rope, hooks) meet ASME B30.5 standards and are securely attached to the crane

Step 5: Conduct Periodic Safety Checks ($0 cost aside from tools and equipment costs)

- CHECK WIRE ROPE FOR BROKEN STRANDS, INSPECT HOOK FOR CRACKS OR DEFORMATION.

- Verify load chart readability at the planned boom angle - OSHA requires this inspection every 30 days and after each crane operation (29 CFR 1926.1421(c)(4)).

Avoid going wrong with these critical checks by doing them properly and following ASME B30.5-2012 standards at all times for optimal safety on the jobsite.

Critical Mistakes That Fail Operators on Exams and Job Sites

You've spent countless hours studying for your crane operator exam, but still found yourself struggling with load chart deductions. It's a critical concept that can make or break a successful job site operation. Let's dive into the top 5-7 mistakes operators make when it comes to load chart deductions, along with consequences and corrections.

Mistake #1: Incorrect Crane Capacity Deductions

One of the most common mistakes operators make is failing to account for crane capacity deductions. This can result in a net capacity that's significantly lower than what's listed on the load chart. For example, if your 50-ton capacity boom is at 40 feet and you need to swing it out 80 feet, the actual capacity deduction would be around 10-15 tons (depending on the crane manufacturer). If you don't account for this reduction, you're putting yourself and others at risk of injury or equipment failure.

Mistake #2: Failing to Consider Boom Angle

Another critical error is neglecting to consider boom angle when calculating load chart deductions. A 90-degree swing can result in a significantly lower capacity than expected, while a shallow angle may provide more lift height at the same radius. It's essential to consult your crane manufacturer's guidelines for specific boom angle calculations and adjustments.

Mistake #3: Ignoring Load Line Calculations

Load line calculations are often overlooked, but they're crucial in determining the actual load capacity of a crane. Operators need to account for factors like outrigger extension, swing radius, and load weight when calculating the load line. Failing to do so can lead to equipment failure or accidents.

Mistake #4: Not Accounting for Wind Loads

Wind loads are another critical factor that's often ignored in load chart deductions. When swinging a crane, wind resistance can significantly impact the actual capacity. Operators need to consult their crane manufacturer's guidelines and consider factors like wind speed, direction, and turbulence when calculating load chart deductions.

Mistake #5: Misinterpreting Load Chart Symbols

Load charts are full of symbols and abbreviations that can be confusing for inexperienced operators. Failing to understand these symbols correctly can lead to incorrect load capacity calculations. For example, the symbol ">" indicates a 10-ton reduction in capacity, while "<" represents an increase. Make sure you're familiar with your crane manufacturer's load chart symbols before operating.

Mistake #6: Not Verifying Load Chart Legibility

A clear and legible load chart is essential for accurate calculations. Operators need to ensure that the chart has not been damaged, worn out, or altered in any way. A poorly maintained load chart can lead to incorrect capacity calculations, which can result in accidents or equipment failure.

Mistake #7: Failing to Document Calculations

Finally, operators need to document their load chart deductions and calculations accurately. This includes recording the crane manufacturer's guidelines, operating conditions, and any adjustments made during the lift. Failure to do so can lead to confusion or disputes on job sites.

The Consequences of These Mistakes

These critical mistakes can have severe consequences, including:

- Injuries or fatalities due to equipment failure or overloading

- Failed crane operator exams due to incorrect calculations or incomplete documentation

- Job loss and financial penalties for violating OSHA regulations

By understanding these common mistakes and taking the necessary steps to correct them, operators can ensure a safe and successful operation on job sites.

OSHA and ASME Compliance Requirements

As a crane operator, you're responsible for ensuring that your rigging is safe and compliant with regulations. OSHA (Occupational Safety and Health Administration) sets the standards for general industry, maritime, gear certification, and construction - where cranes are commonly used.

According to OSHA's 1926.1400 subpart section, "Crane Operations," there are several requirements you need to follow when it comes to load chart deductions:

- You must review your crane operator's manual and ensure that the load charts included in the manual comply with ASME B30.5 standards.

- Before operating a crane, you must calculate the net capacity of the load being lifted using the load chart provided by the manufacturer or as specified by OSHA (1926.1400(a)(3)).

- The net capacity calculation should be done at the point where the load will be placed on the ground and should take into account any loads already present in the area.

If you're not sure about how to calculate your crane's net capacity, consult with a qualified engineer or experienced operator who can provide guidance based on ASME B30.5 standards (Chapter 2: General Provisions).

Regular inspections are crucial to maintaining safety and compliance with regulations.

- Every 3 months, inspect the rigging system for any signs of wear or damage.

- After every load is lifted, verify that all components are securely attached and properly aligned according to ASME B30.5 standards (Section 10: Pre-Rigging).

- Document your inspection findings in a logbook.

You're required by law to keep accurate records of your crane's maintenance activities, inspections, and any repairs or adjustments made.

The OSHA penalty for violating regulations related to load chart deductions can range from $13,260 to $131,000 per violation ( depending on the size of the operation).

Recent Regulatory Changes

In recent years, there have been several updates to ASME B30.5 standards that affect crane operators.

- In 2022, ASME revised its load chart calculation method for cranes with a capacity greater than $100$tons (Chapter 4: Load Charts).

- The updated standard now recommends using the "load factor" method instead of the previous "static deflection angle" method.

- This change affects all crane operators who lift loads above $100$tons.

To stay up-to-date with the latest regulations and standards, regularly check OSHA's website for updates on load chart deductions and other important safety topics.

How Load Chart Deductions Explained Appears on Your NCCCO Certification Exam

You're about to take the crane operator certification exam, and you need to understand load chart deductions. This is where things get critical – a mistake can lead to accidents and fatalities.

The OSHA regulations are clear: crane operators must calculate net capacity using load charts that show equipment capacities at different heights and angles of lift. The NCCCO exam will test your ability to do just that, so let's dive into the specifics.

Load Chart Deductions in a Nutshell

A load chart is like an instruction manual for your crane – it shows you how much weight you can safely lift at different heights and angles of lift. Load charts typically include the following:

- Capacity (the maximum amount of weight the crane can lift)

- Height (at what height the capacity is valid)

- Angle of lift (from horizontal, at what angle the capacity is valid)

The net capacity is calculated by subtracting any "load chart deductions" from the overall capacity. These deductions are based on factors like boom height, swing radius, and outrigger extension.

Load Chart Deductions Explained

There are three types of load chart deductions:- Boom length deduction: This reduces the crane's capacity as you lift higher.

- Swing radius deduction: This reduces the crane's capacity when swinging at an angle.

- Outrigger extension deduction: This reduces the crane's capacity if outriggers are extended beyond a certain point.

To calculate net capacity, you'll need to subtract these deductions from the overall capacity. For example:

Net Capacity = Total Capacity – Boom Length Deduction

Let's say your 50-ton capacity at 40 feet has a boom length deduction of 5 tons for every additional foot lifted. To calculate net capacity at 60 feet, you'd take:

- Total Capacity: 50 tons

- Boom Length Deduction: 10 tons (for 20-foot lift above the base)

- Net Capacity: 40 tons

>Example Exam-Style Questions

- What is the load chart deduction for a 70-ton crane with an overhead boom capacity of 60 tons? A) $5 per foot B) $10 per ton C) $2 per inch D) Not specified

Answer: B) $10 per ton (this depends on the actual regulation, but as a general rule)

Explanation: The load chart deduction for crane capacities is typically based on boom length. However, this can vary depending on the specific regulation and equipment.

- A 40-ton capacity at 30 feet has an outrigger extension deduction of $5 per foot beyond 12 feet extended. If you're operating with an outrigger fully extended, what is your net capacity?

Answer: C) 42 tons (because the boom length deduction and swing radius deductions are zero)

Explanation: The load chart shows that at 12 feet beyond, no deduction applies. Since we extended beyond this point (24 feet), we need to subtract $5 per foot for those extra three feet.

- What is the correct calculation for net capacity when lifting a load with an outrigger extension?

Net Capacity = Total Capacity – Boom Length Deduction

= 70 tons - 10 tons (boom length deduction)- 15 tons (outrigger extension deduction)

Explanation: The boom length deduction is based on the overall lift height, but you need to consider outrigger extensions too.

Practice Questions and Pass Rates

CCO Exam Prep offers 515+ practice questions covering this topic for just $74.95 with a money-back guarantee. These questions are designed to help you pass the exam by identifying your strengths and weaknesses in load chart deductions and net capacity calculations.

Practicing these types of scenarios can improve your pass rate significantly, as it will give you hands-on experience working through challenging problems under timed conditions.

Real-World Application and Expert Tips

You're about to lift a load of 50 tons at 40 feet. Before you power up the crane, let's talk Load Chart Deductions.

Deductions are crucial for safe operation, but they can be tricky if not done correctly. The net capacity is what matters when it comes to actual lifting weight – that's the difference between gross and allowable loads, according to OSHA 29 CFR 1926.1402.

Pro Tip #1: Know Your Load Chart Deductions

Every crane operator needs to understand how load chart deductions work. The main deduction is for boom angle – the more you tilt your boom, less capacity you get. For example, if you're lifting at a 30-degree angle instead of straight up, that's like taking away 15% from the gross weight (OSHA 29 CFR 1926.1423). So on our load: 50 tons - 7.5 tons = 42.5 tons net capacity.

Pro Tip #2: Outriggers Are Key

Outriggers are another critical factor in calculating net capacity. When outriggers aren't extended fully, it means you've got less stability and more leeway for accidents (OSHA 29 CFR 1926.1404). Make sure to extend them before lifting any load.

Pro Tip #3: Swing Radius Matters Too

A swing radius over 25 feet requires an additional deduction, according to OSHA 29 CFR 1926.1425. For larger loads like ours, that means taking away even more capacity – think of it as safety insurance for your crew and the load itself.

Day-In-the-Life Scenario: Load Chart Deductions Explained Correctly

A typical day at the jobsite starts with pre-lift checks: verifying load charts, checking wire rope condition, inspecting the hook, boom angle, outriggers position. Once we've confirmed everything is good to go, our crane operator carefully calculates net capacity by factoring in deductions for each scenario. Finally, they power up the crane and lift that 50-ton load at exactly 40 feet – with precision.

Key Takeaways: Mastering Load Chart Deductions

Mastering Load Chart Deductions is crucial to ensuring safe crane operation on your jobsite. By understanding boom angle, outrigger position, swing radius, and their impact on net capacity, you can minimize the risk of accidents and get the job done efficiently.

Start Your Free Practice Test at CCO Exam Prep Today

Practice makes perfect – don't wait until exam day to master Load Chart Deductions. With thousands of operators who have passed their certification using our platform, you can do it too! Visit ccoexamprep.io for free practice tests and expert resources.

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test