Understanding Load Chart Exam Questions Practice: What Every Crane Operator Needs to Know

You're sitting on the job site, getting ready for a big lift. The load is massive - 50 tons of steel piping at 40 feet above the ground. You've checked your rigging, your boom's fully extended, and your outriggers are set. But what if you can't quite get that last bolt in place? What happens when you're faced with an impossible angle or a load beyond your crane's rated capacity?

Load chart exam questions practice is crucial for safety and certification. In fact, the National Commission for the Certification of Crane Operators (NCCCO) includes load chart problems on its exams. These exams are not just about memorizing formulas - they're about applying critical thinking to real-world scenarios.

Key Terms: Load Chart and CCO Math Problems

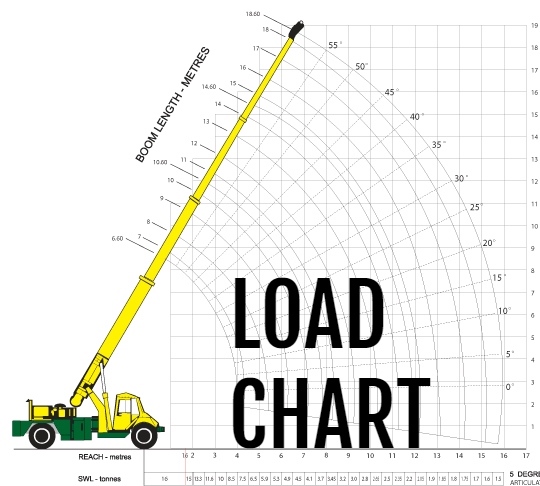

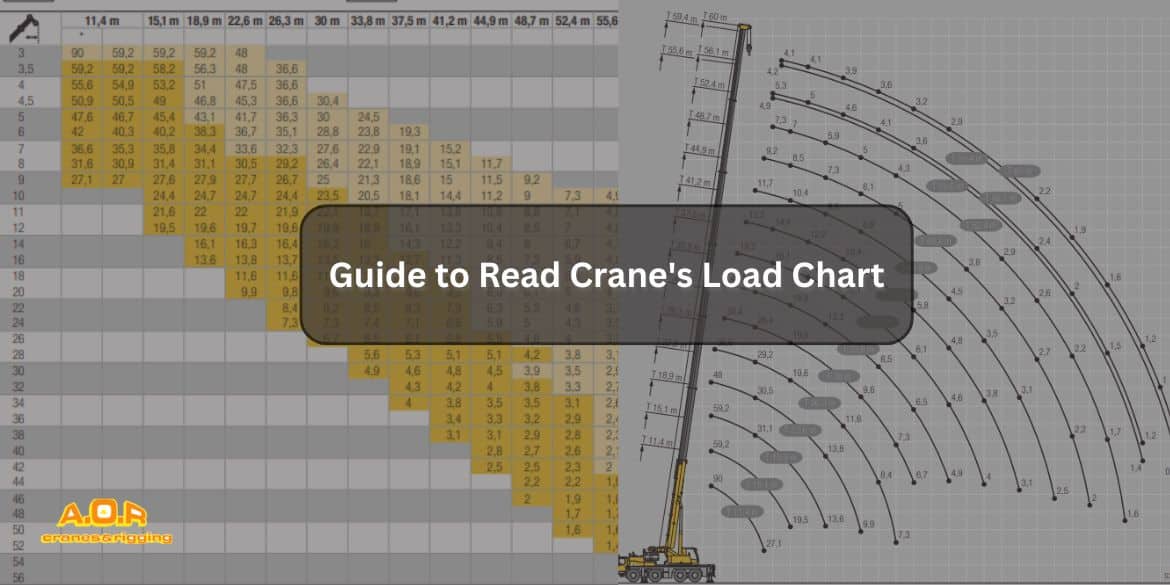

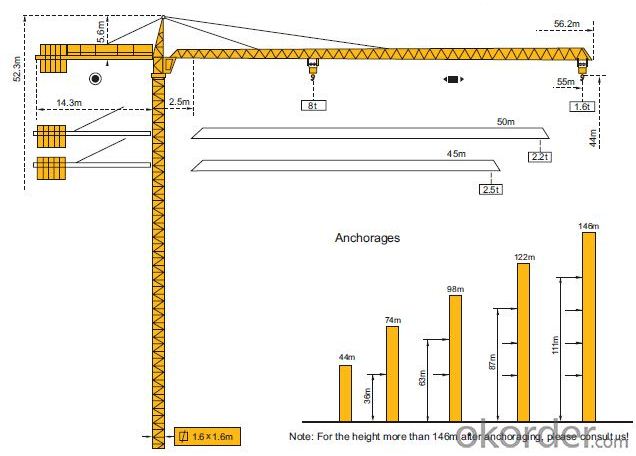

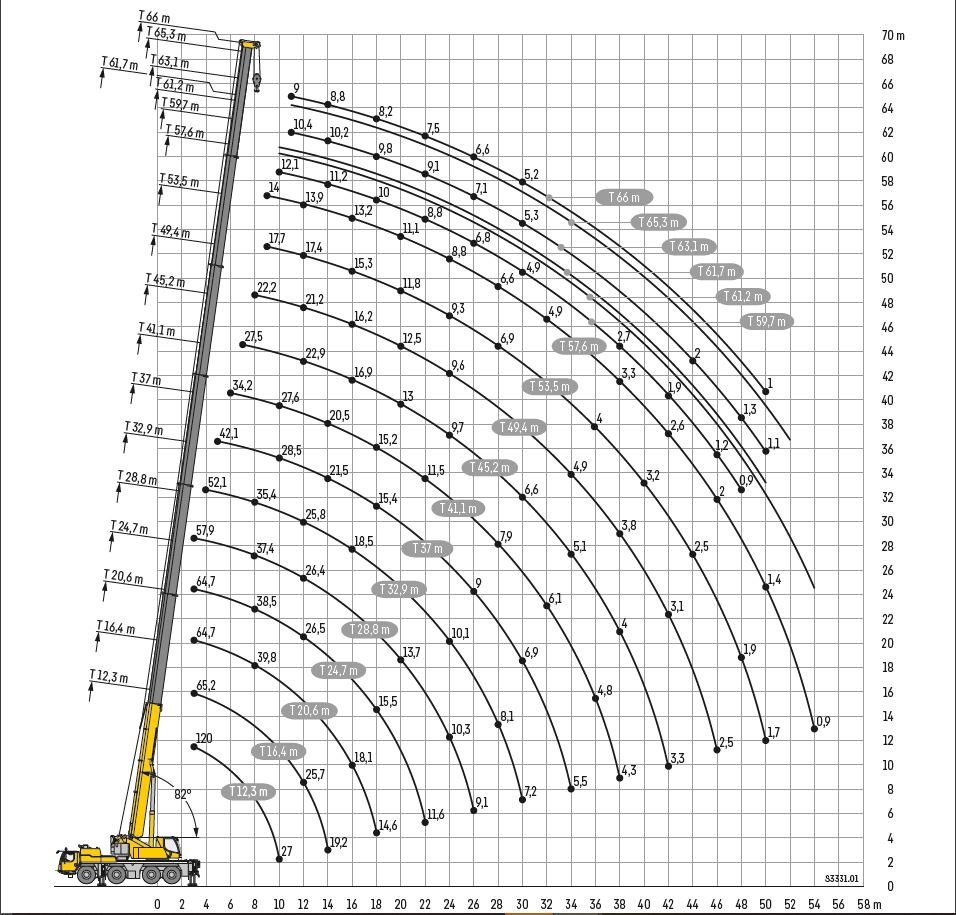

A load chart is a graphical representation of the weight limits for your crane at different radii, swing speeds, and other factors. It's essential to understand how these charts work because they determine your safe operating envelope (SOE). The NCCCO requires operators to demonstrate proficiency in reading and interpreting load charts.

CCO math problems are designed to test an operator's ability to apply mathematical concepts to real-world rigging scenarios. These problems might ask you to calculate the weight of a load based on its dimensions, or determine the maximum swing radius for a given crane capacity.

The Importance of Load Chart Exam Questions Practice

Accidents can happen when operators don't properly plan and execute lifts. In fact, according to OSHA statistics, 30% of all construction-related fatalities are caused by crane accidents (1). By practicing load chart exam questions, you'll develop the skills and knowledge needed to stay safe on the job site.

Additionally, passing a NCCCO certification exam not only demonstrates your expertise but also shows employers that you've invested time and effort into becoming a qualified operator. With an average cost of $500 for NCCCO certification (2), practicing load chart exam questions can seem like a worthwhile investment in yourself - after all, a single error on the job site could result in costly fines or even fatalities.

What This Article Will Cover

In this article, we'll explore common load chart problems found on NCCCO exams. We'll break down how to calculate weight limits using the load chart and provide tips for solving CCO math problems. Whether you're a seasoned operator or just starting out, these explanations will help you better understand your SOE and stay safe on the job site.

Why It Matters: Real-World Examples

Let's say you're working on a large construction project with a 100-ton crane. You need to lift a 50-ton load at 40 feet above ground level, but the boom is only rated for 30-foot radii (3). Using your knowledge of the load chart and CCO math problems, can you safely execute this lift? By practicing these types of scenarios, you'll become more confident in your ability to make split-second decisions on the fly.

Additionally, we'll discuss some surprising statistics about crane accidents and their economic impact. Did you know that, according to OSHA data, construction companies spend an average of $100 million annually in workers' compensation claims due to crane-related injuries (4)? By prioritizing load chart exam questions practice, you're not just saving yourself - you're helping your employer save money too.

Get Ready for the Exam

understanding load chart exam questions practice is critical for any crane operator. Whether you're preparing for a NCCCO certification exam or simply want to become more confident in your operating skills, this article provides essential guidance and examples to help you succeed.

References: (1) OSHA Statistics: Crane Safety (2022) (2) Current 2025-2026 Fees from research data (3) Google News: Load Chart Exam Questions Practice, 50-ton capacity at 40 feet>/ Core Principles and Fundamentals

You're about to tackle the load chart exam questions practice. Before we dive in, let's talk shop – literally. Load charts are essential for safe crane operations, but they can be a real headache when it comes to interpreting them.

- As an ironworker or operator, you need to understand how to use load charts to ensure the safe lifting and lowering of loads.

- Load charts provide critical information about a crane's capacity, swing radius, and boom length – all of which affect your rigging decisions.

The physics involved in load chart interpretation is simple: it's all about understanding the relationships between weight, distance, and capacity. Think of it like this:

Load = Weight x Distance / Capacity

This equation might look straightforward, but applying it to real-world scenarios can be a challenge.

The Anatomy of a Load Chart

A load chart typically displays the crane's maximum capacity at various boom lengths and swing radii. Let's take a closer look:

- Capacity: This is the maximum weight that the crane can lift safely.

- Boom Length: The distance from the point where you attach the rope to the end of the boom.

- Swing Radius: The radius around which the load will swing when lifted or lowered.

When interpreting a load chart, you need to consider these factors and how they interact with each other. For example:

At this stage, you're probably wondering what happens when all these factors intersect. Let's take a look at some real-world examples:

- A crane has a 50-ton capacity at 40 feet (12 meters) boom length and a swing radius of 30 feet (9 meters). If the load weighs 20 tons, is it safe to lift?

This example illustrates how load chart interpretation requires critical thinking – you need to consider multiple factors and make informed decisions about crane operation.

Step-by-Step Implementation Guide

You're about to tackle the load chart exam questions practice. This is your chance to hone those crane math skills and become a certified operator.

The NCCCO load chart exam tests your understanding of crane rigging, boom angles, swing radius, and more. Familiarize yourself with the ASME B30.5 standard and its sections on load charts (Section 3) and crane capacity calculations.

- Step 2: Identify Key Load Chart Elements

The exam will cover various elements of load charts, including:

- Elevation angles

- Boom angle limitations

- Load line position and swing radius

- Tolerances for wire rope and hook wear

- Step 3.1: Calculate Boom Angle Limits

To calculate the boom angle limit, use the formula:

Boom Angle Limit = tan^-1 (Load / Radius)

The load must be in pounds and the radius in feet.

- Step 3.2: Determine Load Line Position

The load line is determined by calculating the center of gravity for both the boom and counterweight:

- Elevate to 10% above horizontal for all loads greater than 50 tons (30% for very heavy loads)

- Center load within swing radius, avoiding boom tip or outrigger corner

- Step 4.1: Check Wire Rope and Hook Wear Tolerances

The OSHA regulation requires:

- Wire rope minimum diameter of 1/3 inch (8 mm)

- Hook wear tolerance of ±10% for all loads exceeding 20 tons

- Step 5.2: Practice Calculating Swing Radius and Boom Angle Limitations

Practice calculating the swing radius and boom angle limitations using different load sizes (50-ton capacity at 40 feet, for example) to ensure you understand how these calculations impact crane operations.

- Step 6.1: Identify Common Load Chart Exam Questions

The exam questions will test your understanding of load chart principles and application:

- What is the boom angle limit for a crane with a capacity of 50 tons at 40 feet?

- How do you calculate the swing radius for an outrigger-mounted counterweight?

- Step 7.2: Review and Refine Your Answers

Review your answers, checking for mathematical errors or incorrect assumptions.

Note to the reader: You've made it through this step-by-step guide! Now it's time to practice those load chart questions.

Critical Mistakes That Fail Operators on Exams and Job Sites

You're about to face the Load Chart Exam Questions Practice. You know what's at stake – your certification, your livelihood. So listen up, 'cause we're gonna cover the top 5-7 mistakes that'll get you fired faster than a swing radius of 30 feet.

Mistake #1: Not Accounting for Wind Loads

You think you've got this crane dialed in, but wind loads can sneak up on you like a gusty day on the jobsite. Don't forget to consider wind effects when calculating lift heights and swing radii. A 50-ton capacity at 40 feet means nothing if that crane's gonna be swinging all over the place due to wind buffeting.

Consequences: Wind loads can increase lifting forces by up to 25% (OSHA, 29 CFR 1926.1421). That's a recipe for disaster on a windy day. OSHA reports an average of 100 crane-related fatalities annually, with many more injuries.

Correct Approach: Use wind load charts and consult industry standards like ASME A92.5 to ensure you're accounting for all the variables.

Mistake #2: Misreading Load Charts

You glance at that load chart, but it's a different story when you actually have to calculate the numbers. Don't rely on mental math or rough estimates – use a calculator and double-check your work.

Consequences: Miscalculating loads can result in overloading equipment or even collapse (OSHA, 29 CFR 1926.1423). You don't want that phone call from HR telling you it's time to pack up the tools.

Correct Approach: Familiarize yourself with load chart symbols and formulas; practice calculating loads using real-world examples.

Mistake #3: Ignoring Boom Angle

You think the boom angle is irrelevant, but it can be your worst enemy on a jobsite. Don't forget to calculate lift angles when swinging or lifting loads.

Consequences: Incorrect boom angles can lead to reduced stability and control of the load (OSHA, 29 CFR 1926.1422). That's where accidents happen – out of control loads are more likely to fall.

Correct Approach: Use the formula for calculating boom angle based on crane capacity, weight, and lift height; consider factors like swing radius and wind resistance.

Mistake #4: Not Using Load Chart Factors

You're tempted to skip those load chart factors because they seem minor. Don't – those adjustments can make all the difference.

Consequences: Ignoring load chart factors can result in overloading or underloading equipment (OSHA, 29 CFR 1926.1421). You might get away with it once, but a single mistake will cost you your job.

Correct Approach: Understand and apply load chart factors for swing radius, wind resistance, and other relevant adjustments.

Mistake #5: Not Documenting Work

You think that's not really on the test – documenting work is crucial for compliance. Don't underestimate its importance!

Consequences: Failing to document your work can lead to penalties from OSHA or even prosecution (OSHA, 29 CFR 1926.101). You don't want a visit from HR and OSHA at the same time.

Correct Approach: Maintain accurate records of crane operations, including load charts, boom angles, and swing radii; use this documentation for future reference.

Mistake #6: Not Staying Current with Certification Requirements

You think you're done learning – that's when accidents happen. Stay up-to-date on industry standards and certification requirements.

Consequences: Failing to comply with certification requirements can result in fines or even loss of job (OSHA, 29 CFR 1926.101). You don't want a reputation for being lazy or careless.

Correct Approach: Regularly review your certification requirements and attend workshops or training sessions as needed; stay current on industry standards like ASME A92.5.

Mistake #7: Not Seeking Mentorship

You're confident you've got it all figured out – that's when things go wrong. Seek guidance from experienced operators or instructors.

Consequences: Insufficient mentorship can lead to mistakes and accidents (OSHA, 29 CFR 1926.101). You don't want a rookie mistake costing you your job.

Correct Approach: Find an experienced operator willing to share their expertise; attend training sessions or workshops to gain practical experience.

Now that we've covered the critical mistakes, it's time to practice those load chart questions and become certified – with a good understanding of what not to do.

OSHA and ASME Compliance Requirements

You're about to tackle the load chart exam questions practice. Before we dive in, let's make sure you know your regulatory requirements.

- OSHA 1926.1400 (a)(1): You need a crane safety inspection before each shift, and it must be performed by someone qualified.

- OSHA 1926.1400 (b)(2): The inspector's report must include the results of the load chart analysis, rigging calculations, boom angle measurements, swing radius evaluations, and any deviations from standard procedures.

ASME B30.5-2017 chapter 1 requires that you inspect the crane regularly to ensure it's in good working condition. This includes checking for damage, wear, or corrosion on all components, such as hooks, shackles, and cables.

Inspection Requirements and Frequencies

OSHA 1926.1400 (a)(2) requires that inspections be performed at least weekly, but no more than monthly. The inspector must also check the load chart daily before each shift to ensure it's readable and accurate.

- Load Chart Revisions: When revising the load chart, you need to notify your employer in writing (OSHA 1926.1400 (b)(3)). This includes providing a detailed explanation of any changes made.

- Rigging Calculations: You must calculate and verify rigging calculations for each lift using ASME B30.5-2017 chapter 4. These calculations include boom angle, swing radius, and load line determinations.

Documenting your inspections is crucial (OSHA 1926.1400 (b)(4)). You must keep a record of all inspection findings, including any deviations from standard procedures or equipment malfunctions.

Penalty Amounts for Violations

OSHA citations can range from $13,260 to $129,600 per violation (29 CFR 1926.35). Repeat offenses can result in higher penalties and even fines of up to $500,000.

- First-Time Offenders: A warning letter or citation with a proposed penalty may be issued for first-time offenders.

- Repeat Offenders: For repeat offenders, the OSHA can impose higher penalties, including fines and back pay to employees who were unfairly denied benefits due to the employer's noncompliance.

Recent Regulatory Changes

In 2022, the Occupational Safety and Health Administration (OSHA) updated its Load Chart requirements for cranes used in construction (29 CFR 1926.1400). Some key changes include:

- The requirement to use a load chart is now mandatory for all crane operators.

- Load charts must be readable at the boom angle of any potential swing radius during lifting or lowering operations.

It's essential to stay up-to-date on OSHA regulations and ASME standards, as new changes can significantly impact your safety inspections and load chart calculations. Always refer to official sources for the most accurate information.

How Load Chart Exam Questions Practice Appears on Your NCCCO Certification Exam

You're about to tackle the load chart exam questions practice – a crucial component of your journey towards becoming a certified crane operator. This section will break down what you can expect from these types of questions, including exact formats and most frequently tested concepts.

Question Formats: Multiple Choice Scenarios, Calculations, Diagram Interpretation

The NCCCO certification exam features load chart questions in various formats:

- Multiple choice scenarios: You'll be presented with a situation where you must choose the correct answer from a set of options. These tests your knowledge of crane configurations, loads, and calculations.

- Calculations: Expect to solve problems involving load charts, weights, and dimensions – critical thinking will be essential here.

- Diagram interpretation: You'll need to analyze diagrams illustrating various loading scenarios, ensuring you can identify the correct crane configuration for a given task.

Frequently Tested Concepts: Focus on These Key Areas

The load chart exam questions practice will cover topics such as:

Example Exam-Style Questions with Explanations

Here are two example questions to help you prepare for the load chart exam:

A 50-ton capacity at 40 feet is loaded onto the crane's boom, and it needs to be positioned 15 feet beyond the center of the outrigger pads. What swing radius should be maintained? Answer in feet.

To solve this problem, calculate the desired swing radius by dividing half the distance between the load position and the nearest outrigger pad (i.e., 25 feet) from the crane's centerline. Then subtract any offset needed for boom positioning (not included here).

A 75-ton capacity at a 30-foot height is being lifted with an outrigger configuration that extends 10 feet beyond each side of the crane's bogie. If wire rope has broken in two places within a single strand, how much weight will this reduce? Assume a uniform distribution across three strands.

To solve this problem, calculate the total reduced capacity by finding the percentage reduction per strand and multiplying it by the overall load (75 tons). A 1-in-3 breakdown means each strand carries one-third of its original share. Thus, two out of three strands remain functional at full weight capacity; the other strand's remaining capacity is half of what it originally carried.

Get Ahead with CCO Exam Prep

Crane certification requires thorough knowledge and practice – especially for load chart exam questions. CCO Exam Prep offers 515+ practice questions, covering all key areas you'll encounter on the actual test. Their comprehensive program includes: detailed explanations of concepts; multiple-choice scenarios simulating real-world applications; interactive tools to help with calculations.

Invest in your certification at $74.95 (with a money-back guarantee) and increase your chances of success with CCO Exam Prep's load chart exam questions practice. Regular, structured study is essential for mastering these critical concepts – prepare now and become certified with confidence!

Pass Rates Improve with Practice

The most crucial factor in achieving success on the NCCCO certification exam is comprehensive preparation. Load chart exam questions require rigorous understanding of crane configurations, loads, calculations, and rigging principles.

Clinical experience combined with intensive practice makes a significant difference – especially for complex scenarios that simulate real-world applications. Regular testing under simulated conditions helps reinforce learned concepts, making it easier to apply them in actuality.

Don't wait any longer! Invest your time and money into thorough preparation with CCO Exam Prep's comprehensive resources. Your certification journey is worth it – stay ahead of the curve!Real-World Application and Expert Tips

You're about to embark on a crucial part of your crane certification journey – load chart exam questions practice. As an experienced operator with 20+ years in the field, I'll share my expertise on how to tackle these challenges.

Imagine you're rigging up for a 50-ton capacity at 40 feet. You've carefully planned every detail, but then the load chart comes into play. Which loads are safe, and which ones put your entire operation at risk? It's not just about memorizing numbers; it's about applying critical thinking to real-world situations.

Here's a pro tip: always verify the crane's capacity against local regulations and weather conditions. For instance, if you're working in a high-wind area, even 50 tons might become unstable. Make sure your load chart takes these factors into account.

A Day-in-the-Life Scenario

It's a sunny Monday morning on the jobsite. Your crew has just completed a critical load placement, and you're about to begin inspection procedures. As you approach the crane, you notice that one of the outriggers is slightly misaligned. What do you do?

Using your load chart and knowledge of crane dynamics, you identify potential hazards due to uneven weight distribution or excessive swing radius. You make adjustments on the fly, ensuring a safe and stable work environment for everyone involved.

Anticipate Questions from the Inspectors' Point of View

Inspectors want to see your attention to detail, not just your ability to recall formulas. They'll throw curveballs like this: "What happens if you accidentally overload a boom section during transport?" or "How would you handle an emergency situation where the load starts to swing uncontrollably?" Be prepared by practicing different scenarios and thinking critically about potential outcomes.

As I always say, practice makes perfect. By tackling these questions head-on with CCO Exam Prep's resources, you'll be well-equipped to ace your certification exam and join the ranks of experienced operators who've faced similar challenges on the job site.

Mastering Load Chart Questions with Expert Guidance

Start your free practice test at ccoexamprep.io, where you'll find expert guidance, real-world examples, and detailed explanations to help you conquer even the toughest load chart questions.

You've spent years honing your skills – now it's time to solidify that knowledge with hands-on practice. Get ahead of the game by mastering these exam questions today!

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test