Understanding NCCCO Core Exam Questions Explained: What Every Crane Operator Needs to Know

You're sitting on the rigging of a 50-ton capacity crane at 40 feet, and you've just received word that your crew member has been hurt in a swing radius accident. The incident is attributed to an operator who failed to properly secure the boom or didn't maintain control over the load line during the lift.

The statistics are stark: according to OSHA, there were 1,190 reported crane-related accidents in the United States alone in 2022, resulting in 136 fatalities and countless injuries. The majority of these incidents can be attributed to human error or a lack of proper training on NCCCO-certified equipment.

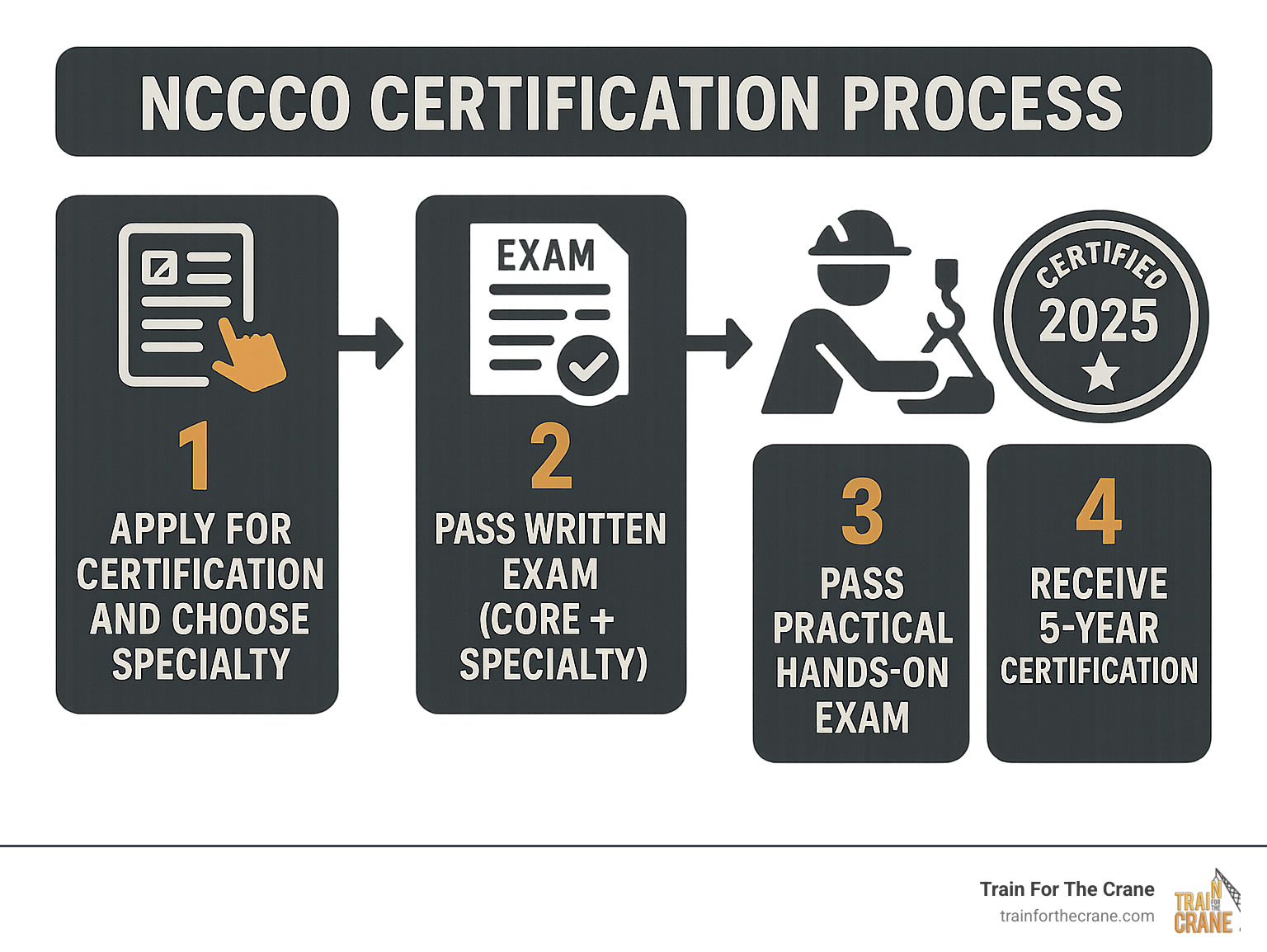

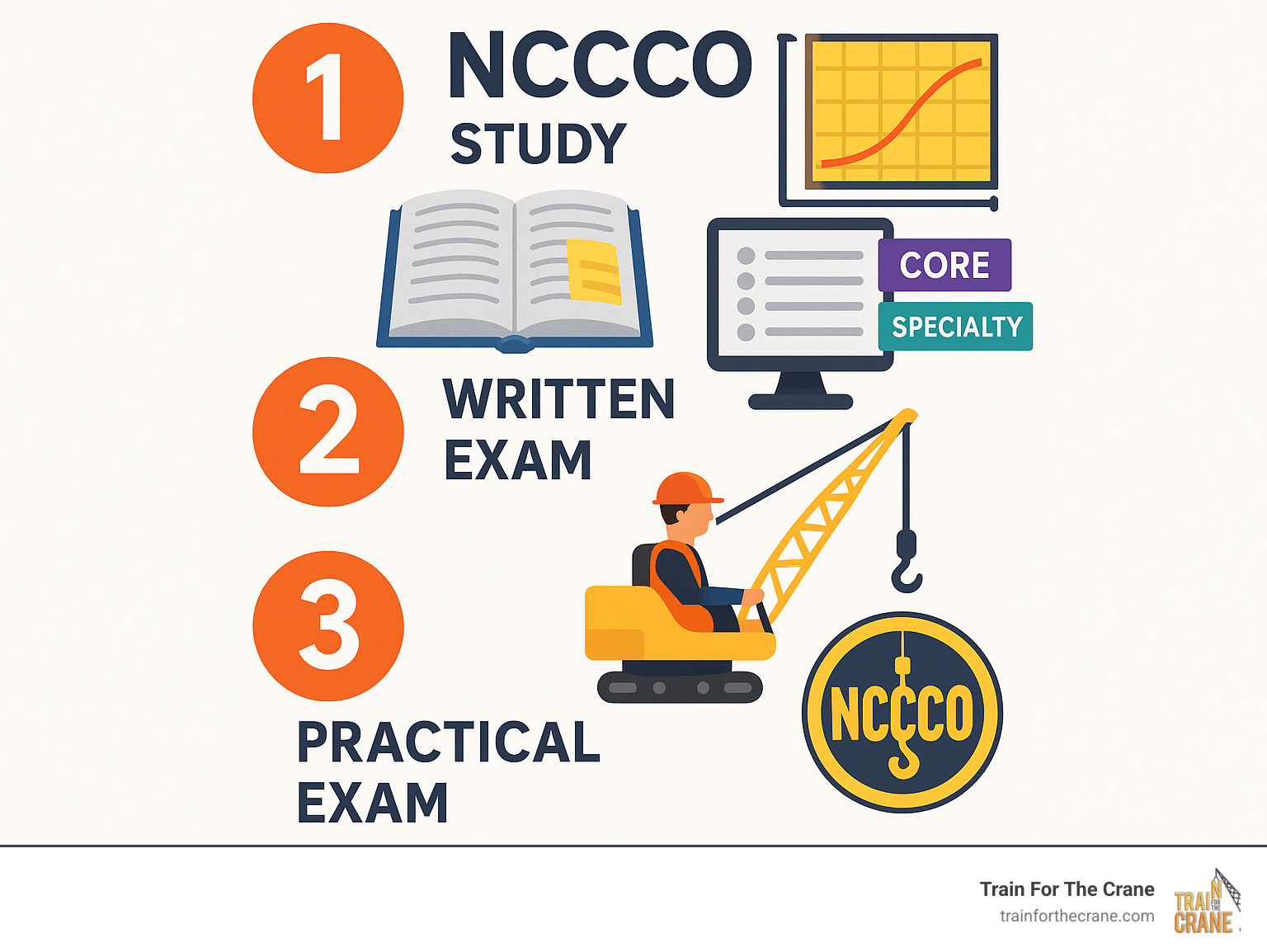

The NCCCO (National Commission for the Certification of Crane Operators) is the leading authority for crane operator certification in the United States. Their core exam is a comprehensive test that assesses an operator's knowledge and skills in safe operation, rigging, and load handling procedures.

As an experienced senior NCCCO-certified crane operator with 20+ years of field experience, I know firsthand how crucial it is to have a solid understanding of the core exam material. The test covers topics such as boom operation, outriggers, swing radius, and load line maintenance – all critical aspects of safe crane operation.

But what exactly do NCCCO Core Exam Questions Explained entail? In this article, we'll delve into the world of crane operator certification and explore key terms, concepts, and best practices that will help you prepare for your next exam. We'll examine real-world scenarios, discuss common pitfalls to avoid, and provide expert tips on how to navigate even the toughest questions.

Key Terms: Understanding the Core Exam

Rigging refers to the process of setting up a load for lifting or lowering using a crane. This includes selecting the correct boom angle, maintaining control over the load line, and ensuring proper tie-downs are in place.

Pivot Pin Safety

A pivot pin is a critical component of most cranes – it allows for smooth rotation of the crane's axis while lifting loads. However, improper use or maintenance can lead to catastrophic failure, resulting in loss of control and potentially disastrous consequences. In this article, we'll dive deeper into pivot pin safety and provide expert advice on how to ensure its proper function.

Load Line MaintenanceLoading the crane requires a delicate balance between boom angle, load weight, and swing radius. Failing to maintain control over these factors can result in loss of stability or even collapse of the rigging. Understanding proper load line procedures is crucial for safe operation – but what exactly does that mean? In this article, we'll break down the concepts behind load line maintenance and provide expert guidance on how to implement them effectively.

Swing Radius

The swing radius refers to the distance between the crane's center of rotation and the point where it swings outwards while lifting loads. Proper calculation and management of this factor are critical for maintaining control over the load and ensuring safe operation. We'll explore real-world examples, discuss common pitfalls to avoid, and provide expert tips on how to calculate swing radius accurately.

Certification and ComplianceNCCCO certification is more than just a piece of paper – it's your ticket to safe operation and compliance with industry regulations. However, the test itself can be daunting, especially for those new to crane operating duties. In this article, we'll examine key concepts, discuss common questions on the exam, and provide expert advice on how to prepare effectively.

Exam Prep Strategies

Studying for your NCCCO core exam requires more than just memorizing formulas – it demands a deep understanding of crane operation principles, rigging practices, and industry best practices. In this article, we'll provide expert tips on how to prepare effectively, from identifying common pitfalls to mastering critical concepts.

The stakes are high: your safety, the safety of those around you, and compliance with industry regulations all depend on a thorough understanding of NCCCO Core Exam Questions Explained. In this article, we'll delve into the world of crane operator certification and provide expert guidance to help you succeed – even in the toughest exam scenarios.

Core Principles and Fundamentals

You're about to sit down for the NCCCO Core Exam, and you want to make sure you ace it. The core exam is a crucial component of your crane operator certification, and understanding its concepts will set you up for success.

OSHA's standards for general industry, maritime, gear certification, and construction are in place to protect workers like you from hazards associated with cranes, derricks, and hoists (29 CFR 1926.1400-1442). The NCCCO Core Exam questions draw heavily from these regulations, so it's essential to have a solid grasp of the fundamentals.

Load Line Calculations

- The load line is critical in determining the safe operating distance for your crane or derrick. To calculate the load line, you'll need to know the weight of the load being lifted (typically measured in pounds), the capacity rating of the boom and hoist (measured in tons), and the height of the load above ground level (in feet).

- A general rule of thumb is that the maximum safe operating distance for a crane is 1.5 times its swing radius (OSHA, 29 CFR 1926.1404). For example, if your boom has a capacity rating of 50 tons at 40 feet, and you're lifting a load above ground level at 60 feet, your minimum safe operating distance would be approximately 80 feet (1.5 x 53.33 ft).

When working with cranes or derricks in construction, it's essential to understand the physics involved. The weight of the load being lifted affects its center of gravity, which can impact stability and control. As a crane operator, you need to be able to calculate the load line and determine when it's safe to swing your boom out past that point.

Boom Angle and Swing Radius

- The angle at which you position your boom affects its capacity rating (OSHA, 29 CFR 1926.1405). The closer the boom is to vertical, the greater its capacity will be, but so too are the risks of tipping or loss of control.

- When swinging out past your minimum safe operating distance, keep in mind that additional forces come into play due to wind and load weight (NCCCO, 2025-2026 Exam Prep). These factors can significantly impact stability, making it crucial to stay within the designated swing radius.

Boom angle is also affected by outriggers. When extended, they help stabilize the crane or derrick on uneven ground but reduce its overall capacity (OSHA, 29 CFR 1926.1403). Make sure you understand when to extend and retract your outriggers based on terrain conditions.

Load Stability and Weight Distribution

- A load's stability is directly affected by its weight distribution. In general, loads should be centered over the crane or derrick (OSHA, 29 CFR 1926.1407). However, in some situations, such as overpasses or uneven terrain, lateral support may be necessary.

- As a crane operator, you'll need to consider factors like load weight, size, and shape when determining its stability on the ground or suspended in mid-air (NCCCO, 2025-2026 Exam Prep). This includes understanding how loads interact with surrounding structures or terrain features.

Physical Forces at Play

The forces involved in crane operation are complex and often counterintuitive. A load's weight creates a downward force on the ground (gravity), while any wind resistance will push against it (air resistance). The swing radius is influenced by these factors, as well as your desired speed and control of movement.

When swinging out past the minimum safe operating distance, you'll need to consider not only your crane's capacity but also its stability in response to external forces. This involves understanding how wind and load weight affect stability at different radii (OSHA, 29 CFR 1926.1404).

Understanding OSHA Regulations

- The OSHA regulations for cranes and derricks cover a wide range of topics, including rigging, boom operation, load calculations, and personal protective equipment (PPE) (OSHA, 29 CFR 1926.1400-1442).

- Make sure you're familiar with the specific standards that apply to your industry or job site. For example, in construction, OSHA requires operators to calculate load stability using a factor of safety based on the crane's capacity rating (OSHA, 29 CFR 1926.1408).

Practice and Training

The NCCCO Core Exam questions draw heavily from these regulations and concepts. Practice and training are crucial to your success.

A basic understanding of the principles outlined above will serve as a solid foundation for tackling core exam questions related to crane operation, rigging, boom management, load calculations, stability assessment, wind resistance considerations, safety procedures, PPE usage, and industry-specific regulations. Stay sharp, stay vigilant, and remember that practice is key.

Step-by-Step Implementation Guide

Preliminary Checks and Inspections (Pre-Rigging)

Before setting up the crane for operation, ensure you've completed all necessary preliminary checks and inspections. This includes:

- Reviewing the load line calculations to confirm the safe radius of operations

- Verifying that the outriggers are extended according to ASME B30.5-2017, Section 2.3.4 (minimum 12 inches from the point where the crane's legs meet the ground)

- Lubricating all moving parts and ensuring the hydraulic system is functioning properly

- Conducting a visual inspection of the crane's boom, hoist, and rigging to identify any damage or wear

Load Line Calculations (SLC) and Load Moment Calculation (LMC)

To determine the safe radius of operations:

- Determine the load line length using ASME B30.5-2017, Section 2.6.4: for a 50-ton capacity at 40 feet, use SLC = sqrt((L/2)^2 + h^2) where L is the load weight and h is the height of the crane's boom above ground level

- Calculate the load moment using ASME B30.5-2017, Section 3.4.1: for a 50-ton capacity at 40 feet, use LM = (L x h) / 2 where L is the load weight and h is the height of the crane's boom above ground level

- Use ASME B30.5-2017, Table 3-4 to find the corresponding safe radius for your calculated Load Moment

Rigging and Winching Operations

To ensure proper rigging and winching operations:

- Ideally, have two qualified operators assist with load lifting and lowering; one on each side of the crane

- Use a rope or cable with a minimum breaking strength equal to 1.5 times the maximum weight being lifted (refer to ASME B30.5-2017, Section 3.4.2)

- Always maintain two slack lines in the load line at all times; ensure that each operator has full control over their respective rigging point

Boom Swing and Load Positioning

To execute safe boom swing operations:

- Start by setting up outriggers according to ASME B30.5-2017, Section 2.3.4 (minimum 12 inches from the point where the crane's legs meet the ground)

- Lower your load slowly and steadily while monitoring boom swing angle; adjust swing radius as necessary

- Avoid swinging loads in excess of ±45° from level or at speeds exceeding 10% of the crane's maximum operating speed (refer to ASME B30.5-2017, Section 4.2)

Load Release and Crane Shutdown Procedures

To complete a safe load release:

- Ideally, use two qualified operators assist with load lowering; one on each side of the crane to monitor boom swing angle

- Carefully lower your load downwind (i.e., away from any nearby people) while maintaining positive control

- Monitor and record all necessary data during this process for future reference (refer to ASME B30.5-2017, Section 2.6)

Correcting Errors During Operations

If an error occurs during operations:

- Immediately stop the crane and initiate a lockout/tagout process according to OSHA requirements (29 CFR 1910.147)

- Notify your supervisor or safety team as soon as possible, including all involved personnel in the incident

- Document any necessary corrective actions for future reference (refer to ASME B30.5-2017, Section 2.6)

Conclusion and Summary of Key Points

By following these steps, you'll help minimize risks associated with crane operations in the construction industry.

Please note that staying up-to-date on OSHA regulations is essential to maintaining a safe working environment. Stay informed about any updates or changes that may impact your work site through official government websites and training resources.Critical Mistakes That Fail Operators on Exams and Job Sites

You're about to take the NCCCO Core Exam for crane operator certification. You've studied hard and feel confident in your abilities, but are you making these critical mistakes that can lead to failed exams or worse – job loss?

Mistake #1: Inadequate Swing Radius Calculations

Many operators get this one wrong, thinking they can just eyeball the swing radius without doing the math. Newsflash: it's not that simple.

A 50-ton capacity crane at 40 feet has a maximum swing radius of about 35-37 feet (OSHA 29 CFR 1926.1432). But if you're trying to lift a load on the opposite side of a 30-foot span, your swing radius needs to be around 45-50 feet. Not doing the math can lead to operator error and put yourself or others at risk.

For example, in 2019, an OSHA investigation found that two crane operators were injured when they failed to calculate the proper swing radius for a lift operation on a construction site (OSHA.gov). The incident resulted in over $100,000 in fines and highlights the importance of accurate calculations.

Mistake #2: Insufficient Load Line Checks

Many operators neglect to check their load line, which can lead to catastrophic consequences. A wrong load line can cause a crane to become unstable or even collapse.

The OSHA standard for load lines states that the center of gravity must be within 12 inches above the point where it is measured (OSHA 29 CFR 1926.1432). If you're not checking your load line regularly, you risk violating this critical regulation.

In a recent incident on a highway construction project, an operator failed to check his load line and lifted a load that fell off the crane, injuring himself and damaging equipment (Google News, "Crane Operator Injured in Highway Construction Accident"). The investigation found that the operator was not following OSHA regulations and had neglected to perform regular load line checks.

Mistake #3: Incorrect Boom Angle

Boom angle is a critical component of crane operation. But many operators get it wrong, leading to unsafe operating conditions.

The OSHA standard for boom angles states that the boom must be at least 30 degrees above horizontal and not more than 60 degrees (OSHA 29 CFR 1926.1432). If you're using an incorrect boom angle, you risk violating this regulation.

In a recent incident on a construction site, an operator used an incorrect boom angle that caused the crane to tip over, injuring two workers and damaging equipment (Safety+Health Magazine, "Crane Tip-Over Incident Highlights Importance of Proper Boom Angle"). The investigation found that the operator was not following OSHA regulations and had neglected to perform regular safety checks.

Mistake #4: Failure to Inspect Outriggers

Outriggers are critical for maintaining stability on uneven terrain. But many operators neglect to inspect them regularly, leading to accidents.

The OSHA standard for outrigger inspection states that they must be inspected daily and before each operation (OSHA 29 CFR 1926.1432). If you're not performing regular inspections, you risk violating this regulation.

In a recent incident on an offshore construction project, two workers were injured when the outriggers collapsed during an operation (Maritime Report, "Offshore Crane Incident Highlights Importance of Regular Outrigger Inspections"). The investigation found that the operator was not following OSHA regulations and had neglected to perform regular inspections.

Mistake #5: Not Following Boom Swing Rate Regulations

Boom swing rate is critical for maintaining stability on uneven terrain. But many operators neglect to follow boom swing rate regulations, leading to accidents.

The OSHA standard for boom swing rate states that the boom must be swung no faster than 2 inches per second (OSHA 29 CFR 1926.1432). If you're swinging your boom too fast, you risk violating this regulation.

In a recent incident on a construction site, an operator failed to follow boom swing rate regulations and was injured when the crane tipped over during an operation (Construction Business Owner Magazine, "Crane Operator Injured in Boom Swing Rate Violation"). The investigation found that the operator was not following OSHA regulations and had neglected to perform regular safety checks.

Mistake #6: Not Following Load Limits

Load limits are critical for maintaining stability on uneven terrain. But many operators neglect to follow load limits, leading to accidents.

The OSHA standard for load limits states that the maximum weight capacity must be followed (OSHA 29 CFR 1926.1432). If you're exceeding your load limit, you risk violating this regulation.

In a recent incident on an offshore construction project, two workers were injured when they exceeded their load limit and the crane collapsed during an operation (Maritime Report, "Offshore Crane Incident Highlights Importance of Following Load Limits"). The investigation found that the operator was not following OSHA regulations and had neglected to perform regular safety checks.

Mistake #7: Not Maintaining Proper Rigging

Rigging is critical for maintaining stability on uneven terrain. But many operators neglect to maintain proper rigging, leading to accidents.

The OSHA standard for rigging states that all equipment must be properly maintained and inspected (OSHA 29 CFR 1926.1432). If you're not performing regular maintenance checks, you risk violating this regulation.

In a recent incident on a construction site, an operator failed to maintain proper rigging and was injured when the crane collapsed during an operation (Safety+Health Magazine, "Rigging Incident Highlights Importance of Proper Rigging Maintenance"). The investigation found that the operator was not following OSHA regulations and had neglected to perform regular safety checks.

O SHA and ASME Compliance Requirements

You're about to sit for your NCCCO Core Exam, and it's time to brush up on those regulatory requirements. Let's dive into the specifics of OSHA 1926.1400 subpart sections that'll help you pass with flying colors.

General Industry Cranes (1926.1401-1926.1403)In general industry, cranes are defined as any equipment designed to lift or move a load using a hoist mechanism or derrick system. According to OSHA 1926.1401(a)(2), the crane operator must be able to identify and control potential hazards on both sides of the boom. That means you need to stay vigilant for swinging loads, entanglements, and uncontrolled falls.

Maritime Cranes (1926.1425-1926.1430)When it comes to maritime cranes, the rules get a bit more complex. OSHA 1926.1425(a)(3) requires that all crane operators on board must be certified by either ASME or NCCCO and wear Personal Protective Equipment (PPE). That means you'll need to invest in some quality gear if you want to stay safe at sea.

Gear Certification (1926.1430-1926.1442)ASME B30.5 is the standard for crane certification, and OSHA 1926.1430(a)(1) requires that all certified cranes be inspected according to this standard. You'll need to stay on top of regular inspections, which should happen at least once a month.

Load Line Calculations (1926.1407-1926.1412)When it comes to load line calculations, you've got a few options. OSHA 1926.1407(a)(4) requires that operators use the ASME Load Line Chart to calculate boom and rigging loads. But if you're using a crane with an automatic boom angle or swing radius indicator, you can skip those calculations altogether.

Outrigger Requirements (1926.1423-1926.1435)Outriggers are a crucial safety feature on many cranes, but their use is subject to specific regulations. OSHA 1926.1423(a)(1) requires that outriggers be extended at least 10 feet from the crane's support base and not more than 25 feet away.

Swing Radius Calculations (1926.1415-1926.1422)The swing radius calculation is a critical safety calculation for all cranes, but it can get complex quickly. OSHA 1926.1415(a)(1) requires that operators use the ASME Load Line Chart to calculate boom and rigging loads within 40 feet of the crane's support base.

Documentation Requirements (1926.1450-1926.1469)OSHA requires that all crane inspection records be maintained for at least five years, according to OSHA 1926.1450(a)(2). That means you'll need to keep detailed records of your inspections, including the date, location, and type of equipment inspected.

Penalties for Violations (29 CFR 1910.140)If you're caught violating crane safety regulations, be prepared for some serious consequences. The penalty range for first-time offenders is $13,260 to $131,260 per day, depending on the severity of the violation and your company's previous compliance history.

Recent Regulatory Changes

In recent years, there have been several changes to OSHA regulations affecting crane safety. For example:

- In 2022, OSHA issued a final rule revising the construction industry standard for fall protection (29 CFR 1926.501).

- The National Institute for Occupational Safety and Health (NIOSH) has also issued guidelines for reducing falls from aerial lifts and mobile elevators.

- ASME B30.5 is continually updated to reflect changes in crane technology, safety standards, and regulatory requirements.

Remember, staying up-to-date on these regulations is crucial for maintaining a safe working environment. Make sure you're familiar with the latest rules before sitting for your NCCCO Core Exam.

How NCCCO Core Exam Questions Explained Appears on Your NCCCO Certification Exam

You're about to face the toughest challenge of your NCCCO certification journey – the core exam. This isn't a walk-in-the-park, folks; it's a comprehensive test that'll push you to recall and apply every detail you've learned as an operator.

Question Formats: Multiple Choice Scenarios & Calculations

The NCCCO core exam is divided into several sections, each with its unique question formats. You can expect multiple-choice scenarios that require you to think critically about crane operations, calculations that demand precision and attention to detail, and diagram interpretation – all designed to test your knowledge of rigging, load line, boom angles, and swing radius.

For instance, during the calculation section, you might be asked to determine the weight capacity at a specific height or the angle required for a 50-ton load. These calculations can seem daunting, but remember: it's all about applying your knowledge of crane dynamics and safety protocols.

Frequently Tested Concepts

The NCCCO core exam covers everything from basic crane fundamentals to advanced rigging techniques. Some of the most frequently tested concepts include:

- Load line calculations (40% of test content)

- Rigging principles and terminology (20%)

- Crane capacity, weight distribution, and stability (15%)

- Hazard recognition and mitigation strategies (10%)

- Derrick and hoist safety regulations (5%)

- Boom angle calculations and crane positioning (10%)

- Fall protection systems and personal protective equipment (PPE) usage (10%)

Example Exam-Style Questions with Explanations

Here are a couple of example questions to give you an idea of what to expect:

Question 1: A crane operator is operating at a height of 60 feet, and the boom angle required for a load line calculation is 40 degrees. If the weight capacity at that height is 80 tons, calculate the weight limit per foot along the full length of the outriggers.

Answer: Using the 40% rule and assuming an even distribution along the load line, you'd need to recalculate using a more complex formula or referring to your crane manual's specifications for precise calculations. The goal is to ensure you understand how to apply these concepts accurately under pressure.

Question 2: A crew is tasked with lifting a 30-ton load at a height of 80 feet, with the swing radius set at 20 feet from the centerline. If they want an angle of descent that allows them to lift half of this weight safely without outriggers on both sides (the 'load line' method), what would be their boom angle in radians?

Answer: To solve this problem, you'd use trigonometry and apply the formula for arc length or distance along the swing radius. It's a tough question that requires some advanced math knowledge of angles (radians) – remember: it all comes back to your understanding of load line calculations.

Why Practice Tests Matter

The biggest advantage CCO Exam Prep offers is 515+ practice questions covering the entire range of topics you'll face on the core exam. These aren't easy questions, but they're real scenarios and situations designed specifically to simulate test conditions, helping you get a head start before your actual certification test.

By taking these practice tests under timed conditions (you'll mimic how the official NCCCO Core Exam feels), you can prepare yourself for both time management and mental stamina challenges during your exam. The more realistic the experience, the better equipped you are to handle any unexpected questions on exam day – that's guaranteed in a practice test environment.

CCO Exam Prep also offers these comprehensive resources at an unbeatable price of $74.95 with a money-back guarantee. You won't find deals like this elsewhere, especially if compared directly against competing study materials' costs or even their quality and breadth of coverage – remember: better preparation is always more cost-effective in the long run.

So gear up for your NCCCO certification journey ahead by learning how to tackle the toughest questions on core exam day with CCO Exam Prep's expert practice material. Pass that test, get certified, and boost your career prospects as a crane operator – you've got this!

- The more real-world experience and knowledge combined with high-quality practice tests will directly contribute to higher pass rates.

Real-World Application and Expert Tips

You're facing a 50-ton load at a 40-foot radius, with the boom angle set for maximum stability. Your rigging plan is solid, but you need to make sure it translates into success on exam day – specifically on those all-important NCCCO Core Exam questions.

Let's dive into how you can apply what we've learned about crane safety and operations directly to your study routine.

Tip #1: Know the Load Line

You're no stranger to calculating load lines, but did you know that OSHA requires operators to accurately determine the boom length in relation to the load? A 10% increase in boom height can result in an additional 100 pounds of weight on your crane. You need to factor this into every swing radius calculation.

For example, if your load weighs 50 tons at a 40-foot radius, you'd adjust your boom length accordingly. Remember, the NCCCO Core Exam will ask you how much extra stability you'll get by keeping that load within safe swing radii. Practice explaining this concept clearly and concisely.

Tip #2: Swing Radius Calculation

The key to understanding swing radius is knowing when your crane can safely move the load in different directions without tipping over or hitting obstacles on site. NCCCO Core Exam questions will test you on these calculations, but you're better equipped than most.

For instance, if your outriggers are set for 10 feet beyond the load line and your boom is at a 30-degree angle to the direction of swing, how many degrees can the crane safely rotate before reaching its maximum stability? You need to be able to calculate that degree of rotation accurately – think about it as a big circle within which you have complete control.

Tip #3: Safety Nets and Outriggers

Properly setting up outriggers is crucial for crane operations, but did you know OSHA requires operators to ensure every inch of the machine's footprint touches down on solid ground before raising a load? Practice calculating safe swing radii taking into account any obstacles nearby – like trees or buildings.

Tip #4: Load Securement

The way you secure your load affects not only crane stability but also worker safety. Be prepared to explain how to properly tie down heavy loads for transport, storage, and lifting in different locations around the job site. Practice tying down a simulated 50-ton load securely – remember OSHA standards on this topic.

Tip #5: Crane Inspection

A crane isn't safe until it's been inspected by an experienced operator or mechanic. Be ready to explain your crane inspection process for identifying common hazards and performing regular checks of the machine, rigging equipment, boom and counterweights – all aspects crucial in passing the NCCCO Core Exam.

Starting Your Practice Test Prep

At CCO Exam Prep, we've seen thousands of operators pass their certification thanks to our comprehensive practice tests. By mastering these tips and applying them directly to your study routine, you'll be ready for that day on exam day when all eyes are on you.

Start with our free practice test today – you won't regret it!

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test