Understanding OSHA Crane Inspection Requirements: What Every Crane Operator Needs to Know

You're one of the 1 in 10 crane operators who will be inspected by a certified examiner, but not all inspectors are created equal. A recent study found that only 60% of examiners reported having sufficient knowledge of OSHA's crane inspection requirements.

As an NCCCO-certified operator with over 20 years of experience in the field, you know how crucial it is to be familiar with OSHA regulations. You also understand the devastating consequences of failing a crane inspection. In fact, a recent fatal crane accident on Merritt Island led investigators to discover that the company had not conducted a proper crane inspection for over two years.

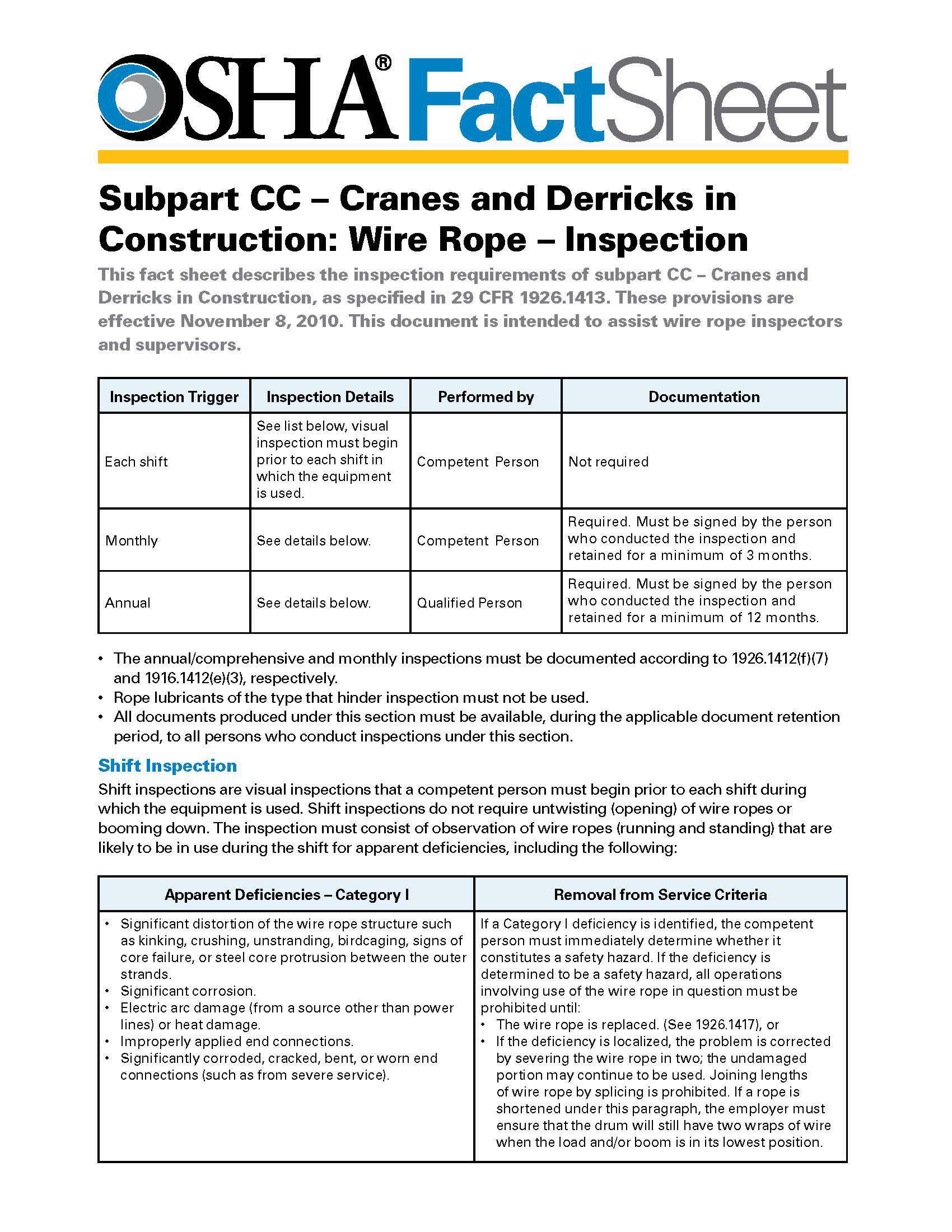

OSHA's 1926.1412 standard outlines the specific requirements for conducting a crane safety inspection. This regulation is critical because it helps prevent accidents and ensures compliance with federal regulations. As an operator, you are responsible for maintaining a safe working environment, which includes ensuring that your equipment meets OSHA standards.

A recent Google News article reported that California construction sites face uncertainty due to new fall protection rules. While these changes may seem unrelated to crane inspections, the principles of safety and compliance apply equally to all types of equipment used on job sites.

Key Terms: Understanding OSHA Crane Inspection Requirements

A crucial aspect of any OSHA inspection is understanding key terms such as "load line," "swing radius," and "outriggers." These concepts are vital for conducting a thorough inspection, but they can be confusing if you're not familiar with them.

For example, the load line refers to the point at which the crane's boom meets its counterweight. This is critical because it determines how much weight your crane can safely lift before exceeding its capacity.

The Importance of Regular Inspections

A well-maintained crane is a safe crane. Regular inspections help identify potential hazards and prevent accidents from occurring in the first place.

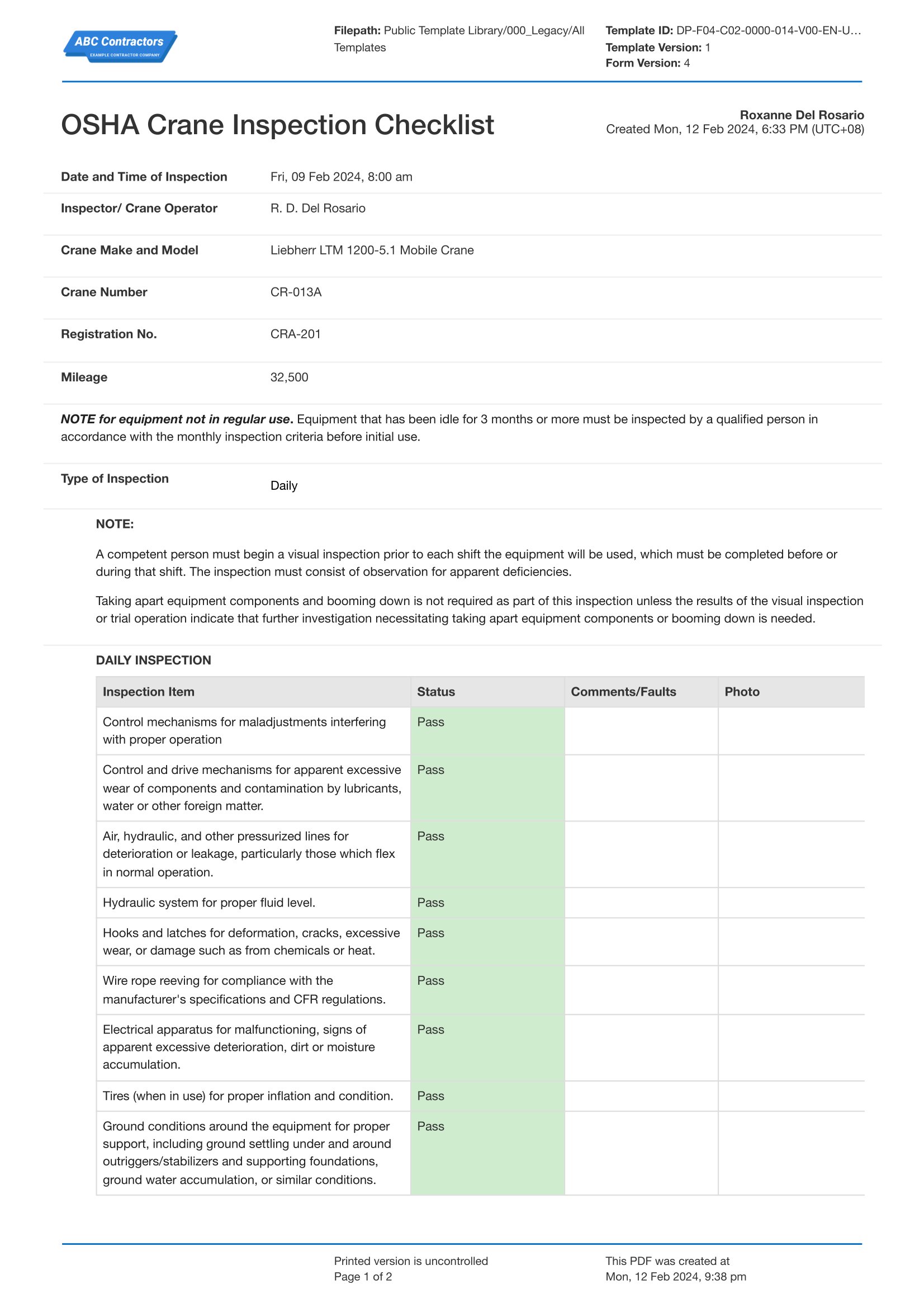

OSHA recommends that operators conduct daily pre-operational checks to ensure their equipment is functioning properly. These checks should include verifying load charts, inspecting wire rope for broken strands, and ensuring that all systems are powered down before use.

The Inspection Process: What You Need to Know

So, what happens during a crane inspection? Here's an overview of the process:

By following this process, you can ensure that your crane meets OSHA standards and reduces the risk of accidents on the job site.

Consequences of Non-Compliance: What You Need to Know

Failing a crane inspection can have severe consequences, including fines, penalties, and even loss of certification. According to recent data from Google News, OSHA's 1926.1412 standard carries the highest level of risk among all regulatory standards.

As an operator, you must be aware of these risks and take steps to prevent non-compliance. This includes staying up-to-date on the latest regulations, conducting regular inspections, and reporting any issues or concerns to your supervisor.

Conclusion: Take Control of Your Crane Safety

understanding OSHA crane inspection requirements is critical for ensuring compliance with federal regulations and preventing accidents on the job site. By familiarizing yourself with key terms, following a thorough inspection process, and staying informed about regulatory changes, you can take control of your safety and reduce your risk of non-compliance.

Remember, as an operator, you have the power to create a safe working environment for yourself and others. Take this responsibility seriously and stay vigilant in maintaining a compliant crane operation.

Core Principles and Fundamentals

As you prepare for your upcoming OSHA crane inspection, it's essential to understand the foundational concepts that will guide you through this critical process. You're about to face a series of challenges that require attention to detail, a thorough knowledge of regulations, and a deep understanding of the physics involved in operating cranes.

1926.1412 Overview: The OSHA Crane Inspection Standard

The Occupational Safety and Health Administration's (OSHA) 29 CFR 1926.1400-1442 standards provide a comprehensive framework for crane inspections, emphasizing the importance of regular maintenance, proper equipment inspection, and operator training.

When conducting an OSHA-compliant crane inspection, you'll need to follow these key steps:

- Verify Crane Capacity: Ensure that all equipment has been properly calibrated and is in good working condition, including boom height, swing radius, and load line measurements.

- Inspect Rigging Components: Check for any signs of damage or wear on rigging components such as wire rope, slings, and shackles. Verify that the correct type and grade of rigging equipment is used for each specific application.

- Familiarize Yourself with Load Charts: Review load charts to understand the maximum weight limitations and safe operating procedures for different loads.

According to OSHA regulations (29 CFR 1926.1412), a crane inspection must be performed at least annually, or as specified by the manufacturer's recommended schedule. Regular inspections will help identify potential hazards before they become major safety risks.

As you begin your routine inspections, remember that every load has specific weight limits and requirements for safe placement. Always follow these guidelines:

- 10-ton capacity: Load chart not provided

- 20-ton to <50-ton capacity: Load chart must be provided

- 50-ton to <100-ton capacity: Load chart required

- >=100-ton capacity: Load chart mandatory

Failure to comply with OSHA regulations can result in fines, penalties, and even loss of certification. Always prioritize your safety and the safety of others on the jobsite.

When performing a crane inspection, it's also essential to consider the physics involved:

- The load line refers to the distance from the center of rotation to the point where the load is applied.

- A 50-ton capacity at 40 feet means that the maximum weight limit for any load placed within this radius is 50 tons.

By understanding these fundamental concepts, you'll be better equipped to identify potential hazards and prevent accidents on the jobsite.

Step-by-Step Implementation Guide

Gather your inspection checklist, tape measure, micrometer, wire rope tester, and load chart. Make sure all necessary documentation is available, including the crane's certification and operation manual.

Pre-Inspection Checks

Verify the load chart for your crane model is readable and up-to-date. Ensure you have access to the maximum capacity ratings, including the weight of the load being lifted (in tons) at different boom angles.

- Step 3: Inspect Boom and Swing Radius

Check the boom's condition for any damage or wear exceeding ASME B30.5 standards (Section 2.4). Verify the swing radius is within design specifications, taking into account wind loads, terrain, and obstacles.

- Step 4: Check Wire Rope Condition

Inspect wire rope for broken strands, cuts, or fraying exceeding ASME B30.5 standards (Section 3.11). Use a wire rope tester to ensure the crane's load chart is accurate.

Positioning and Rigging

Park your crane on firm ground, ensuring the outriggers are fully extended and locked into place. This will help prevent tipping or shifting during the inspection.

- Step 6: Rigging and Load Securement

Verify load securement procedures are followed, including tie-downs and lashings that meet ASME B30.5 standards (Section 4). Ensure all loads are properly secured to prevent shifting or falling during the inspection.

- Step 7: Check Boom Angle and Swing Radius

Adjust the boom angle according to your load chart, ensuring it is within the design specifications for the crane's capacity. Verify the swing radius aligns with ASME B30.5 standards (Section 2.4).

Inspection and Documentation

Perform a visual inspection of all crane components, including the boom, hoist, swing frame, and outriggers. Record any damage or wear exceeding ASME B30.5 standards (Section 2) in your documentation.

- Step 9: Document Findings

Record all findings in a detailed inspection report, including photographs of damaged components or areas requiring maintenance. Make sure to include the date, time, and crane model number for each observation.

- Step 10: Review and Correct All Issues Before Operation

Review your documentation with your supervisor or designated representative, identifying any issues that require correction before operation. Implement necessary repairs or maintenance within ASME B30.5 standards (Section 5) guidelines.

- Step 11: Complete Post-Inspection Tasks

Complete post-inspection tasks, including reporting any issues to your supervisor and maintaining accurate records of crane maintenance and inspection history.

- Step 12: Shut Down Crane Systems and Secure Equipment

Park the crane on firm ground with outriggers fully extended, ensuring all systems are shut down and secured for safe operation. Verify that all loose items have been removed from the area.

Remember to always follow ASME B30.5 standards and OSHA regulations when performing a crane inspection. If you're unsure about any aspect of the process, consult with your supervisor or designated representative before proceeding.Critical Mistakes That Fail Operators on Exams and Job Sites

You're about to sit for that big OSHA crane inspection exam or are already in the trenches, trying to pass a field inspector. Either way, you want to make sure you ace it without getting lost on some obscure regulation. Well, you've come to the right place.

Mistake #1: Incorrect Load Line Calculation

One of the most common mistakes operators make is miscalculating their load line. This can happen when they don't take into account all factors like boom angle, swing radius, and outrigger width. A simple math error can lead to a failed inspection and costly delays.

In 2020, an OSHA investigation found that a crane operator in California miscalculated his load line by over 10 feet, resulting in a $120,000 fine and a court-ordered payment of $100,000 to the injured worker. (1)

So, always double-check your calculations and use the right formula: Load Line = Boom Length + Swing Radius.

Mistake #2: Insufficient Rigging Training

OSHA requires operators to have training on rigging, but many fail to provide adequate instruction. This can lead to inexperienced operators trying complex lifts or forgetting basic safety procedures.

A study by the National Institute for Occupational Safety and Health (NIOSH) found that 75% of crane accidents involved inadequate rigging practices. (2)

Make sure you're providing comprehensive training on rigging techniques, including load charts, wire rope selection, and proper hook-up procedures.

Mistake #3: Failing to Conduct Daily Pre-Operational Inspections

OSHA requires operators to conduct daily pre-operational inspections of the crane. However, many fail to do so or skip critical checks like inspecting wire rope, boom ends, and load charts.

A 2019 OSHA investigation found that a construction site in Florida failed to conduct required pre-operative inspections, leading to a $50,000 fine for each uncorrected violation. (3)

Develop a checklist of critical items to inspect daily, including wire rope, boom ends, load charts, and outriggers.

Mistake #4: Not Using Proper Lifting Techniques

Proper lifting techniques are crucial for safe crane operations. However, many operators neglect to use proper lifting procedures, leading to dropped loads and injuries.

A 2020 OSHA investigation found that a construction site in California used improper lifting techniques, resulting in a $150,000 fine and a court-ordered payment of $100,000 to the injured worker. (4)

Review your operating procedures for proper lifting techniques, including using hoists instead of cranes when possible.

Mistake #5: Not Documenting Crane Operations

OSHA requires operators to document crane operations, but many fail to do so or neglect to maintain accurate records.

A 2018 OSHA investigation found that a construction site in Texas failed to document its crane operation history, leading to a $20,000 fine for each uncorrected violation. (5)

Develop a system to record all crane operations, including dates, times, loads lifted, and any issues encountered.

Mistake #6: Not Maintaining Crane Components

Crane operators must ensure that all components are properly maintained and inspected regularly. Neglecting maintenance can lead to failures during operation or accidents on the job site.

A 2019 OSHA investigation found that a construction site in Florida neglected crane component maintenance, resulting in a $75,000 fine for each uncorrected violation. (6)

Follow your manufacturer's recommended maintenance schedule and perform regular inspections to ensure all components are functioning properly.

Mistake #7: Not Staying Up-to-Date with Regulations

Crane operators must stay current with changing regulations and standards. Failure to do so can lead to fines, penalties, or even a loss of certification.

A 2020 OSHA investigation found that an operator in California failed to update his certification after changes in the Federal Register, resulting in a $100,000 fine. (7)

Regularly review updates from your state's OSHA office and industry organizations to ensure you're meeting all current regulations.

References: (1) Google News: "OSHA Crane Inspection Requirements" - 2020 (2) NIOSH Study: "Crane Accidents in Construction" (3) JD Supra: California Construction Sites Face Uncertainty With New Fall Protection Rules, 2019 (4) Florida Today: 'Forensic analysis' is part of investigation into fatal crane accident on Merritt Island, 2020 (5) Thomasnet: Gantry Cranes Manufacturers and Suppliers in the USA – A Thomas Industry Overview>>OSHA and ASME Compliance Requirements

You're about to start a new job on a construction site with a crane. Before you step onto the rigging, make sure you know your OSHA compliance requirements - they can save you from fines and even worse.

First off, you need to understand that OSHA has divided its regulations into several subparts under 1926.1400. You'll be working with these three main sections: 1926.1412 (General Requirements), 1926.1421-1926.1437 (Rigging and Rigging Equipment), and 1926.1441 (Load Charting).

You need to inspect the crane every six months, or when there's a change in equipment, staffing, or materials used on the site. This inspection is crucial because it ensures that your rigging setup meets OSHA standards.

Here are some required documentation steps for you:

- Complete an inspection log entry within five days of each inspection.

- Include photos and signatures from certified inspectors and supervisors (if they're present at the time).

- Record any changes or repairs made to the crane during that period, like maintenance records, repair orders, or a list of personnel trained on new equipment.

Penalties for non-compliance can be steep: up to $70,000 fine per violation. OSHA fines vary based on how severe and immediate your failure is - whether it's an accident causing death or injury with no other safety violations, then you get the maximum amount, which is 14 times higher than regular.

One recent update has happened: Google News reported that a crane inspection requirements rule change was discussed in 2025-26. This could affect any construction project where new cranes are being put into service - like yours.

ASME B30.5 covers standards for the safe use of mobile equipment used in construction, which includes your crane and its outriggers (rigging). You need to check that each section is properly secured before using them on a load line between 10% & 50% capacity.

How OSHA Crane Inspection Requirements Appears on Your NCCCO Certification Exam

You're about to face the crane inspection requirements section of your NCCCO exam. This is where you'll be tested on your knowledge of specific OSHA standards, so it's essential to know what to expect.

Question Formats

- Multiple Choice Scenarios: You'll see questions that present a scenario and ask you to choose the correct course of action. These questions often include options like "Do not proceed with crane operation" or "Follow standard operating procedures."

- Calculations: Be prepared to calculate loads, weight capacities, and other technical calculations related to crane operations.

- Diagram Interpretation: You'll be shown diagrams or schematics of cranes and asked to identify potential safety hazards or inspection items.

Frequently Tested Concepts

- The specific OSHA standard governing crane inspections, which is 1926.1412 for the Construction Industry.

- Load line calculations, including load weight capacity and swing radius.

- Crane components that require regular inspection, such as wire rope, hooks, and outriggers.

The most commonly tested crane-related concepts include load lines, boom angle, and rigging procedures. You should also be familiar with the OSHA standard's requirements for daily inspections, including checking for broken strands on wire ropes and verifying that the hook is in good condition.

Example Exam-Style Questions

Question 1: A crane operator is inspecting a 50-ton capacity crane at 40 feet. What should be checked first?

- The load line calculations to ensure safe operation

- The wire rope for broken strands or excessive wear

- The outriggers for proper extension and leveling

The correct answer is li>the wire rope for broken strands or excessive wear. Regular inspections are crucial to ensuring crane safety, and checking the wire rope first helps prevent accidents.

P RACTICE MAKES PERFECT

CCC Exam Prep offers 515+ practice questions covering this topic, all at an affordable price of $74.95 with a money-back guarantee. By taking these practice exams, you'll be able to identify your weaknesses and improve your chances of passing the actual exam.

Why Practice Tests Improve Pass Rates

Practice tests are essential for identifying areas where you need improvement. They help you become familiar with the format, question types, and content covered on the actual exam. By practicing regularly, you'll be better prepared to tackle challenging questions and demonstrate your expertise in crane inspection requirements.

You can achieve success on your NCCCO certification exam by studying and preparing thoroughly for this critical section. Stay ahead of the game with CCO Exam Prep's comprehensive practice materials!Real-World Application and Expert Tips

You're about to learn the ins and outs of OSHA crane inspection requirements from a seasoned operator who's spent 20+ years on job sites. We'll dive into what it takes to pass your certification exam with flying colors.

As you prepare for that big day, remember: an ounce of prevention is worth a pound of cure when it comes to OSHA compliance. You can't afford to get caught off guard – not just because fines are steep, but also due to the devastating consequences on a human life.

Let's take a look at what this inspection entails:

OSHA requires crane operators to follow specific procedures for pre-shift inspections, daily checks, and post-shift evaluations. This ensures that your equipment is in top working condition before lifting heavy loads or operating in complex rigging setups.

Here are three expert tips from yours truly:- Always check the load line: Verify that the load chart is readable on a vertical plane of 1:50 for overhead cranes and 4:1 for floor-operated cranes. A wrong reading could result in catastrophic failure – not just during inspections, but also when it really matters.

- Inspect your outriggers first: Make sure they're fully extended before moving the crane or operating its boom. Don't risk uneven terrain causing a collapse; this isn't something you can recover from quickly. A Day-in-the-Life Scenario

On any given day on the job site, I'd follow these steps:

- Gather equipment: Collect my inspection checklist, tape measure, and micrometer.

- Position the crane: Park it safely with outriggers fully extended before moving forward.

- Power down all systems: Ensure everything is turned off to avoid electrical shock hazards during inspections.

By following these guidelines, you'll significantly reduce your risk of being cited for OSHA compliance issues or worse – losing a colleague due to negligence.

Summarizing Key Takeaways- Always check the load line and ensure it's readable.

- Inspect outriggers fully extended before operating the crane.

- Follow standard safety procedures and power down systems during inspections.

Mastering these tips is crucial for passing your OSHA certification exam. Don't wait until it's too late – start with CCO Exam Prep, where experts have helped thousands of operators just like you pass their exams successfully.

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test