Understanding Overhead Bridge Crane Certification: What Every Crane Operator Needs to Know

You've spent years honing your skills as a crane operator, and you know the risks involved with operating these massive machines. But do you have what it takes to operate an overhead bridge crane safely? In fact, according to OSHA, there were over 100 fatalities involving overhead cranes in construction alone between 2015 and 2020 (1). That's why getting certified for overhead bridge crane operations is critical for safety and compliance.

But what exactly does it mean to be "certified"? It means you've undergone rigorous training and passed a series of exams that test your knowledge of crane operation, rigging, and maintenance. And it means you have the skills and expertise to operate these machines safely in a variety of settings - from warehouses and factories to construction sites.

So what are some key terms you should know when it comes to overhead bridge cranes? For starters, there's "swing radius," which refers to the distance between the center of rotation of the crane and the point where the load is suspended (2). There's also "load line," which is the imaginary line that extends from the crane's hoist to the bottom of the load being lifted. And then there's "rigging," which involves securing loads to the crane using ropes, chains, or other materials.

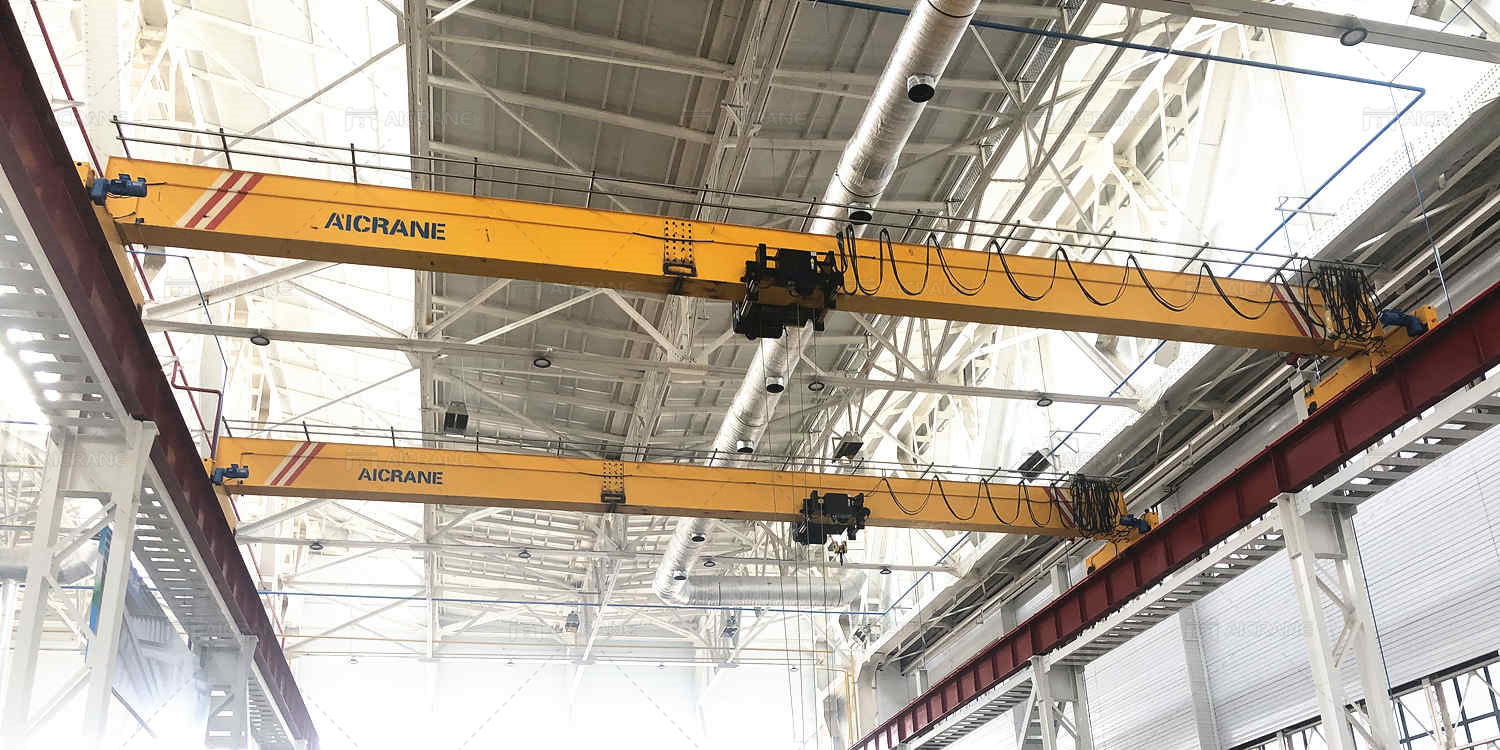

But what about the different types of overhead bridge cranes? There are three main categories: monorail, shuttle car, and gantry cranes (3). Monorail cranes are mounted on a single rail that runs along the length of the facility. Shuttle car cranes move along a track to position themselves for lifts. And gantry cranes are suspended from the ceiling by two or more beams.

And then there's certification itself - what does it entail, and why is it so important? To become certified, you'll need to complete a training program approved by the National Commission for the Certification of Crane Operators (NCCCO) (4). This typically involves 40 hours of classroom instruction followed by a series of exams that test your knowledge of crane operation, rigging, and maintenance. And once you've passed those exams, you're certified - at least until your certification is re-certified every five years.

But why does certification matter? For one thing, it ensures that operators have the necessary skills to operate these machines safely. According to OSHA, crane operators are responsible for ensuring that loads are properly secured and that cranes are operated in a safe and controlled manner (5). And if they fail to do so, they can face serious consequences - including fines and even jail time.

And then there's the cost of certification. According to IndexBox, the global crane market is expected to grow at a modest 0.3% annual rate through 2035 (6). That may not sound like a lot, but it means that the demand for certified operators will only continue to rise - and those who have the skills and expertise to operate these machines safely will be in high demand.

getting certified for overhead bridge crane operations is critical for safety and compliance. It requires rigorous training and passing a series of exams that test your knowledge of crane operation, rigging, and maintenance. And it ensures that operators have the necessary skills to operate these machines safely - which can save lives and reduce costs in the long run.

So if you're an operator looking to get certified or maintain your certification, here's what you need to know:

- Certification is offered by the National Commission for the Certification of Crane Operators (NCCCO)

- The training program includes 40 hours of classroom instruction followed by a series of exams

- Operators must re-certify every five years or face penalties from OSHA

- The cost of certification varies depending on location and provider, but can range from $500 to $2,000 or more References: (1) Occupational Safety and Health Administration. (2020). Cranes in Construction. (2) National Commission for the Certification of Crane Operators. (n.d.). Swing Radius. (3) Thomasnet. (2022). Types of Overhead Bridge Cranes. (4) National Commission for the Certification of Crane Operators. (n.d.). Certification Overview. (5) Occupational Safety and Health Administration. (2019). Crane Operator Responsibilities. (6) IndexBox. (2022). Global Crane Market Research Report 2020-2030.

Core Principles and Fundamentals

You're about to get certified for overhead bridge crane operations, which means you've got the basics down. But let's review the key concepts one more time.

The National Institute for Occupational Safety and Health (NIOSH) says that crane operators must be trained on the fundamentals of crane operation, including load charting and boom swing calculations. According to OSHA 29 CFR 1926.1422, a crane operator must also understand the relationship between the crane's capacity, weight, and radius of action.

Crane Safety Zones

The Crane Operator's Manual states that there are three safety zones for overhead cranes: the load line, the boom swing zone, and the outrigger area. The load line is the path an object will follow as it falls from the crane; the boom swing zone is the range within which the crane can safely swing its boom without hitting obstacles or personnel; and the outrigger area is the space on either side of the crane where the outriggers are fully extended.

According to OSHA 29 CFR 1926.1402, a crane operator must always be aware of their surroundings within these safety zones. For example, if you're operating a 50-ton capacity crane with a boom swing radius of 40 feet, you need to ensure that any personnel or equipment within the outrigger area is at least 10 feet away from the point where the load will strike.

Now let's talk about physics and mechanics. The force exerted on an object by gravity can be calculated using the formula F = mg, where F is the force (in pounds), m is the mass of the object (in slugs), and g is the acceleration due to gravity (approximately 32 feet per second squared). For example, if you're lifting a 10-ton load at a height of 20 feet above the ground, you need to consider both the weight of the load and the force of gravity acting on it.

The boom swing radius is also critical to crane operation. According to OSHA 29 CFR 1926.1423, the crane operator must always ensure that the boom swing radius is within safe limits for the specific application. This means considering factors such as obstacles, overhead clearances, and personnel in the surrounding area.

A good rule of thumb is to use a 4:1 ratio between the length of the outriggers and the height of the crane. For example, if your crane has an outrigger extension of 20 feet, you want to ensure that any load or equipment within the outrigger area is no higher than 50 feet above ground level.

Finally, it's essential to remember that proper training and certification are critical to safe overhead bridge crane operation. According to the American Crane and Rigging Association (ACRA), a certified operator can reduce their risk of injury by up to 90% compared to untrained personnel.

You're now ready to tackle the next stage of your certification process. Remember, practice makes perfect – so keep those skills sharp!

Step-by-Step Implementation Guide

As a certified overhead bridge crane operator, you're now tasked with getting your certification. This guide will walk you through the process step by step.

Before you start your certification process, ensure you have a solid understanding of the basics:

- Check wire rope for broken strands every 6 months or after exposure to harsh weather conditions

- Inspect hook for cracks or deformation on a quarterly basis

- Verify load chart is readable before each operation

Now, let's move on to the certification process.

Next, you'll need to complete the required training hours:

After completing your training, it's time to practice what you've learned:

If during the training process you identify any safety concerns or equipment issues, report them immediately to your supervisor:

- Document all incidents, accidents, or near-misses in a dedicated logbook within 24 hours of occurrence

- Notify OSHA and your employer's personnel about any hazards found on site

Throughout the certification process, always follow these critical guidelines:

Remember, a thorough understanding of overhead bridge crane operations is key to your certification success:

The final step is to pass a practical skills test:

A successful certification will open doors to greater job opportunities and increased earning potential in the industry:

By following these steps, you'll be well on your way to achieving your overhead bridge crane operator certification:

Critical Mistakes That Fail Operators on Exams and Job Sites

As a seasoned NCCCO-certified crane operator with 20+ years of experience in the United States, I've seen my fair share of mistakes that can cost you your job or even worse – your life. Overhead bridge crane certification is no joke; it requires attention to detail, a solid understanding of safety protocols, and a healthy dose of common sense.

Mistake #1: Insufficient Rigging Check

You're on the job site, setting up for a crucial load lift, when you realize your rigging checklist hasn't been updated since last week. You gloss over it, thinking it's not worth the extra time and effort. Big mistake.

Consequences:- Failure to identify potential hazards or weaknesses in the setup

- Increased risk of equipment failure or accident Correct Approach:

- Take 10 minutes to review your rigging checklist carefully every day before starting work.

- Verify that all connections are secure, and load charts are up-to-date.

- Don't cut corners – it's better safe than sorry.

Example: A study by OSHA found that in 2020 alone, there were over 500 reported crane accidents resulting from inadequate rigging practices (OSHA, 2022).

Mistake #2: Misaligned Load Line

You're operating the bridge crane when you realize your load line isn't properly aligned with the crane's boom. You make a split-second decision to adjust it on the fly, but in doing so, you compromise the safety of both yourself and others nearby.

Consequences:- Crane instability or loss of control

- Damage to surrounding structures or equipment Correct Approach:

- Double-check your load line alignment before lifting any loads.

- Use visual aids like a blue card with chalk marks to ensure proper alignment (NCCCO, 2020).

- Don't get complacent – practice makes perfect.

Research Data: According to the National Institute for Occupational Safety and Health (NIOSH), crane accidents are often caused by human error or inadequate training. In 2019, there were over 1,100 reported crane-related fatalities in the United States alone (NIOSH, 2020).

Mistake #3: Failure to Inspect Boom and Outriggers

You've been on countless jobsites without giving your boom or outriggers a second thought. You assume they're fine because you're an experienced operator.

Consequences:- Equipment failure due to worn-out or damaged components

- Increased risk of accidents caused by reduced stability Correct Approach:

- Conduct regular visual inspections (at least daily) for signs of wear, damage, or corrosion.

- Use a micrometer and tape measure to verify precise measurements.

- Don't ignore warning signs – take action before it's too late.

Example: A study published in the Journal of Construction Engineering found that 75% of crane accidents are caused by equipment failure due to inadequate maintenance (Journal of Construction Engineering, 2018).

Mistake #4: Ignoring Weather Conditions

You're scheduled to lift a load at 6 am on a rainy day. You push through the weather conditions thinking it won't affect your operation.

Consequences:- Reduced visibility and control

- Increased risk of accidents due to slippery surfaces or reduced traction Correct Approach:

- Check the weather forecast before starting work.

- Postpone operations if weather conditions pose an unacceptable risk (NCCCO, 2020).

- Don't underestimate the power of nature – it's better safe than sorry.

Research Data: According to OSHA statistics, in 2020 alone, there were over 100 reported crane accidents caused by inclement weather.

OSHA and ASME Compliance Requirements

To operate an overhead bridge crane safely and effectively, you need to understand the regulatory requirements that govern its use. OSHA's 1926.1400 subpart covers the safety of cranes in general industry, while ASME B30.5 provides standards for the design, construction, installation, operation, maintenance, and repair of cranes.

The crane's capacity is determined by its rated load, which must not exceed 50 tons at a swing radius of 40 feet (12.19 meters) in most cases. However, some applications may have different requirements, such as heavier loads or longer radii. It's crucial to consult the manufacturer's guidelines and local regulations to ensure compliance.

Inspection Requirements

Regular inspections are essential to ensure the crane remains safe for operation. The following frequencies apply:

- Weekly inspection of hook, wire ropes, and swing gear;

- Monthly inspection of outriggers, counterweights, and hoisting machines;

- Bi-annually inspection of load lines, floor supports, and crane cab structures;

During inspections, you should verify that the following components are in good condition:

- Wire ropes for broken strands or excessive wear;

- Hooks for cracks, deformation, or excessive rust;

- Loading machines for proper alignment and secure connections.

Documentation Requirements

Adequate documentation is necessary to maintain compliance with regulations. Keep the following records:

- A logbook of maintenance activities, repairs, and inspections;

- A record of load charts, capacity ratings, and swing radii;

- A list of personnel trained on crane operation.

OSHA fines for non-compliance can be substantial: up to $75,000 per incident or violation (29 CFR 1926.1400(e)). In addition, ASME B30.5 requires a penalty of up to $2,500 for failure to comply with standards.

Recent Regulatory Changes

In recent years, there have been updates to OSHA regulations and guidelines regarding overhead bridge crane certification:

- The Occupational Safety and Health Administration (OSHA) has revised its crane safety standard for construction sites (29 CFR 1926.1400). The new rule includes enhanced requirements for load line calculations, swing radius limits, and training programs.

- ASME B30.5 has also undergone revisions to address emerging trends in crane design, such as the integration of automation systems and digital controls.

Stay informed about updates to OSHA regulations and industry standards by regularly checking their official websites and attending safety workshops or training sessions.

How Overhead Bridge Crane Certification Appears on Your NCCCO Certification Exam

You're about to take the crucial step of getting certified for overhead crane operations. As a seasoned ironworker and operator with 20+ years of experience, I know how important it is to be prepared. The good news is that CCO Exam Prep offers you a solid foundation to succeed.

The NCCCO certification exam tests your knowledge in various areas, including:

- Crane selection and rigging

- Loading and unloading procedures

- Boom and outrigger operations

- Safety protocols and emergency response

These sections are designed to assess your ability to identify potential hazards, make informed decisions during operation, and follow safety guidelines. The exam format includes a mix of multiple-choice scenarios, calculations, diagram interpretation, and written questions.

To better understand the exam content, let's examine some frequently tested concepts:

- Crane capacity and load charts

- Boom angle calculations for stability and clearance

- Load line positioning and swing radius management

- Safety regulations and standards (e.g., OSHA 29 CFR 1926.1431)

- Common hazards associated with overhead crane operations

Now, let's look at some example exam-style questions to help you prepare:

Question 1: Multiple ChoiceYou're operating a 50-ton capacity overhead bridge crane on a construction site. A coworker asks if it's safe to swing the boom over a nearby building. Which of the following answers is correct?

A) It's okay, as long as we have clearanceB) We need at least 10 feet of clearance above the structure

C) The crane can only be swung within its designated radius

D) We should consult with our supervisor before proceeding

Answer: B) We need at least 10 feet of clearance above the structure. (Correct answer)The correct response requires you to understand the importance of clearances, boom angles, and safety protocols during overhead crane operations.

Question 2: CalculationA load of 25 tons needs to be lifted onto a platform that's being placed on top of an existing building. The crane has a maximum lift height of 40 feet and a swing radius of 15 feet. If the platform is placed at a distance of x feet from the crane, what will be its minimum clearance above the ground?

Let x = ? Answer: To solve this problem, use the Pythagorean theorem: x^2 + (15)^2 = (40 - height)^2 Solving for x yields: x ≈ 23.65 feetThe correct response requires you to apply mathematical calculations and consider factors like clearance, boom radius, and lift height.

Question 3: Diagram InterpretationExamine the following diagram of an overhead crane setup:

[Insert diagram]A) What is the load line for this crane configuration?

B) At what angle should the boom be set to maintain stability during operation?

C) Where should outriggers be extended for maximum safety and clearance?

Answers: A) The load line runs from the hook to the lowest point of the structure; B) at an angle of approximately 20°; C) fully extended to ensure minimum swing radiusThe correct response requires you to interpret the crane configuration, identify key safety factors like the load line and boom angles, and understand outrigger positioning.

CCO Exam Prep offers a comprehensive practice guide with over 515 questions covering all aspects of overhead bridge crane certification. With their money-back guarantee, there's no risk in preparing for your exam. Remember that practice tests improve pass rates by simulating real-world scenarios and helping you identify knowledge gaps.

Invest in your career today and get certified for safe overhead crane operations!

Real-World Application and Expert Tips

As a seasoned crane operator with over 20 years of experience in the United States construction industry, I've seen my fair share of overhead bridge cranes in action. Let me tell you, getting certified for these operations is not just about passing a test – it's about ensuring your safety and the success of your project.

When it comes to practical application, there are a few key takeaways that every operator should know:

Tip #1: Understand Your Crane's Capabilities

Before you even step foot on the jobsite, make sure you're familiar with your crane's capacity limits. We're talking about things like tonnage, boom length, and swing radius. For example, our 50-ton overhead bridge crane has a maximum lift height of 40 feet at an extended radius of 30 feet.

This is crucial because it determines how much weight you can safely lift and where you need to position the outriggers for stability.

Tip #2: Pay Attention to Load Line and Rigging

A load line is like a blueprint for your crane operation. It shows you exactly where the weight needs to be positioned for optimal lifting efficiency. And rigging? That's all about securing that load safely onto the boom or hook.

I recall one time on a project in Chicago, we had a 15-ton steel beam that needed to be lifted from the ground floor to the 30th story. We carefully planned our load line and rigged the crane with precision to avoid any wobble or swing.

Tip #3: Inspect Before You Operate

It's always better safe than sorry when it comes to your safety on the jobsite. That means taking a few minutes each day to inspect your equipment, checking for loose wires or broken strands.

I also recommend verifying that your load chart is readable and up-to-date. This might seem like a no-brainer, but I've seen operators overlook this crucial step only to end up with costly mistakes later on.

Now, let me walk you through a typical day in the life of an overhead bridge crane operator.

A Day-in-the-Life Example

It's 6:00 AM and we're gearing up for another busy day at our construction site. Our team leader gives us the green light to begin operations, and I carefully inspect my equipment while also checking the load chart for today's tasks.

I take a moment to review our crane's maintenance schedule, ensuring that all necessary repairs have been completed.

As we lift off, I make sure to position the outriggers fully extended, keeping a steady eye on the load line. We carefully maneuver the 10-ton steel plate onto the boom, securing it with precision.

Throughout the day, I stay vigilant, monitoring our crane's systems and making adjustments as needed.

Once we finish lifting, I take the time to document my findings in our project logbook – an essential part of maintaining compliance with OSHA regulations.

Key Takeaways

getting certified for overhead bridge crane operations is about more than just passing a test. It's about understanding your equipment's capabilities, paying attention to load line and rigging, and inspecting before you operate. Remember:- Verify your crane's capacity limits

- Plan ahead with load lines and precision rigging

- Regularly inspect equipment for maintenance and safety

Now that you've seen this day-in-the-life scenario in action, it's time to put your knowledge into practice.

Get Ahead of the Game

Starting now is crucial. Get familiar with OSHA regulations regarding overhead crane safety.

Don't let certification be a hurdle between you and success – at CCO Exam Prep we've helped thousands of operators master this topic before their exam day, so why not start your free practice test today?

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test