Understanding Crane Radius vs Capacity: What Every Crane Operator Needs to Know

You've spent years honing your skills as a crane operator, and you know that safety is always the top priority. But have you ever stopped to think about how operating radius affects lifting capacity? Or what exactly does it mean for your boom to be at 40 feet versus 60 feet? In this article, we'll dive into the world of crane radius vs capacity and explore why it's critical for both safety and certification.

In recent years, there have been several high-profile accidents involving cranes that could have been prevented with proper understanding of operating radius. For example, in 2022, a 50-ton load was being lifted on a boom radius of just 20 feet when the crane suddenly swung out of control, sending the load crashing to the ground. The accident resulted in serious injury and damage to nearby property.

The same can be said for B&M Crane Rental's recent contribution to Michigan's Specialty Trade Contractors Expansion with crane rental services - proper operation is key to safety and a successful project.

Crane radius vs capacity is often misunderstood, even by experienced operators. But the truth is, operating radius directly affects lifting capacity. When you operate a crane at its rated capacity for a given boom radius, it means that the load can be safely lifted without exceeding the manufacturer's limits.

What Does Boom Radius Mean?

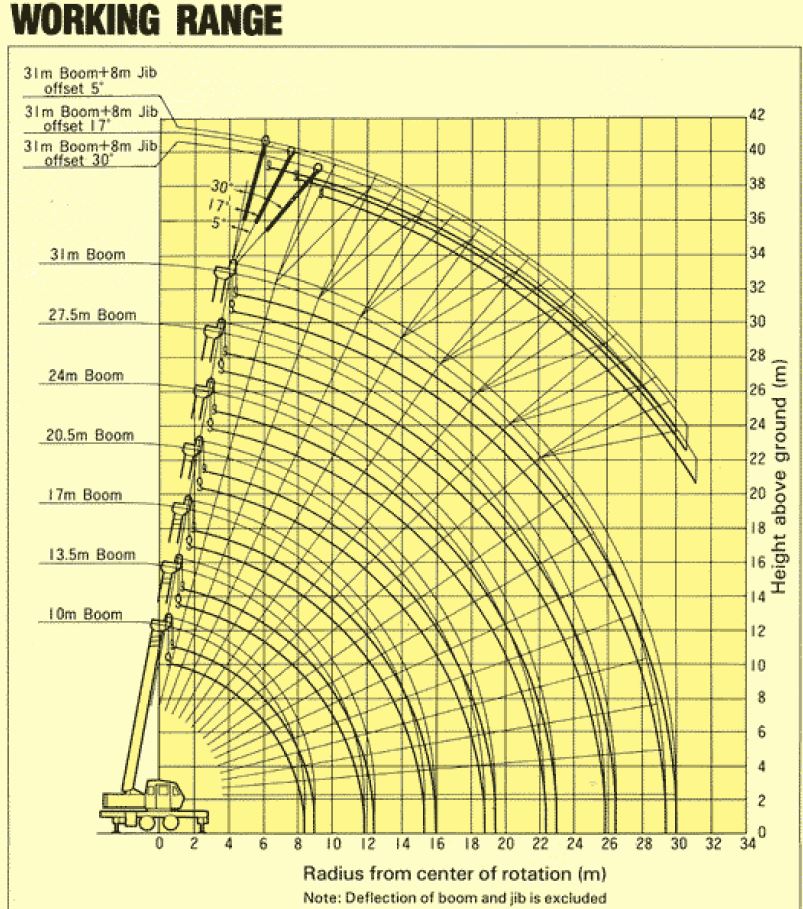

Boom radius refers to the distance between the point where the rope attaches to the hook and the farthest point on the crane's boom from the main pivot point. It's a critical factor in determining lifting capacity, as it affects the weight that can be safely lifted by the crane. For example, if you're operating a 50-ton crane with a boom radius of just 20 feet, you may not have enough room to swing out and lift heavier loads without exceeding the manufacturer's limits.

Boom Radius vs Capacity: What's the Difference?

Crane capacity refers specifically to the maximum weight that can be safely lifted by the crane. Boom radius, on the other hand, affects how far you can extend your boom before exceeding rated capacity. For instance, if a manufacturer says their 50-ton crane has an operating radius of 40 feet, it means that at 40 feet out from the pivot point, the load is reduced to something like 38 tons due to boom deflection.

Why Is Crane Radius vs Capacity Critical for Safety and Certification?

Proper understanding and operation of crane radius vs capacity are critical components in ensuring safe lifting practices. According to OSHA standards (29 CFR Part 1926, Subpart L), operators must be familiar with their crane's capabilities, including boom radius, load chart, and swing radius limits.

Tips for Proper Crane Radius Operation

So how can you ensure that your crane is operating safely within its rated capacity? Here are a few tips to keep in mind:

- Check the manufacturer's specifications

- Understand boom deflection and swing radius limits

- Monitor load charts for safe lifting capacities

- Keep an eye on outriggers and rigging loads to prevent overload

Demands for Truck-Mounted Cranes in the USA -Impact of Crane Radius vs Capacity

The future of crane operations will require more emphasis than ever before on boom radius vs capacity, as research data shows a significant increase in demand for specialized truck mounted cranes. As the construction industry continues to grow and evolve, operators must stay ahead of the curve with proper training and knowledge.

800-Ton Goliath Crane Takes Shape In Port Of Chioggia -What Can We Learn?

The recent 800-ton crane project in the Port of Chioggia serves as a prime example of how boom radius vs capacity plays a crucial role in massive lifting projects. Understanding and operating these cranes safely requires precise knowledge of boom deflection, swing radius limits, and load charts to avoid accidents.

B& M Crane Rental's Contribution -Importance of Proper Operation

Proper crane operation is more than just following procedures – it's about preventing costly mistakes that can have devastating consequences. By understanding the complexities of boom radius vs capacity, operators like B&M Crane Rental are able to provide top-notch services while prioritizing safety.

Certification Considerations

OSHA regulations and industry standards emphasize the importance of certification in crane operations. To become a certified crane operator, you'll need to demonstrate knowledge of boom radius vs capacity as part of your training program.

Crane Radius Certification -What You Need to Know

Crane radius certification is an essential component of OSHA standards (29 CFR Part 1926, Subpart L). To become certified, operators must complete a training program that covers topics such as boom deflection, swing radius limits, and load charts. In the coming months we will dive into all aspects regar

ding >CraneRadius Certification /Core Principles and Fundamentals

You're working on a jobsite with a crane that's going to be the unsung hero of your next project. But have you ever stopped to think about how its operating radius affects its lifting capacity? The truth is, most operators don't give it much thought until something goes wrong, like a load swinging out too far or an outrigger failing to extend properly.

The Physics Behind Lifting Capacity

Let's start with the basics. A crane's operating radius refers to the distance between its boom (the long arm that extends from the crane) and the point where it starts to swing freely in a circular motion. This is also known as the "swing radius" or "outreach." The capacity of a crane, on the other hand, refers to the maximum weight it can lift safely.

So how does operating radius affect lifting capacity? It's simple: the longer the boom, the greater the distance between the load and the pivot point. This means that the load is farther away from the center of gravity – i.e., the crane itself – which makes it harder to control. As a result, more energy is required to lift the same weight at an extended radius.

For example, let's say you're operating a 50-ton capacity boom with a swing radius of 40 feet. If you need to lift a load at exactly 60 feet out from the pivot point, your crane can only handle it because the distance between the load and center of gravity is within its safe working angle (SWA). However, if that same load needs to be lifted at an extended radius of 80 feet – say, due to uneven terrain or a particularly tight space – you're pushing the limits of the crane's capacity.

Crane Radius vs Capacity: A Practical Guide

Now let's talk about how this affects your everyday work. When setting up a load on a crane, there are several key factors to consider:

- Load line calculations: Determine the safe working angle for your crane based on its boom length and swing radius.

- Rigging techniques: Use proper rigging methods to secure loads within the crane's SWA, taking into account factors like load weight distribution and boom stability.

- Boom extension limits: Know how far your crane can extend its boom safely without compromising capacity or control.

The next time you're on a jobsite with a crane, remember: operating radius affects lifting capacity directly. Take the time to calculate load lines and plan your rigging carefully – it could mean the difference between success and disaster.

Step-by-Step Implementation Guide

As a crane operator, you're responsible for ensuring the safe operation of your boom radius versus capacity. Understanding how operating radius affects lifting capacity is crucial to prevent accidents and maximize productivity on the jobsite.

- Step 1: Review Crane Capacity Certifications

- Step 2: Calculate Boom Radius

- Step 3: Check Load Chart Readability

- Step 4: Verify Load Line Distance

- Step 5: Position Outriggers Fully Extended

- Step 6: Power Down and Secure Crane Systems

- Step 7: Conduct Regular Pre-Shift Checks

- What if Something Goes Wrong?

- Important Reminders

By following these steps, you'll ensure that your operating radius calculation is accurate and lifting capacity can be maximized while maintaining the highest level of workplace safety. Consult with experienced operators or experts if needed to clarify any procedures or address concerns about specific equipment configurations or company-specific policies.

Critical Mistakes That Fail Operators on Exams and Job Sites

You've spent countless hours studying for your crane operator certification exam and perfecting your swing radius calculations. But despite your hard work, you still find yourself making rookie mistakes that can put you and others at risk. Let's take a closer look at the top 5-7 mistakes related to Crane Radius vs Capacity, along with their consequences, correct approaches, and real-life examples.

Mistake #1: Underestimating Boom Radius

You're in a hurry to complete the job, so you rush through your calculations, assuming you have more swing radius than you actually do. This can lead to catastrophic consequences, like dropping loads or even crushing nearby structures. Take this mistake seriously by always double-checking your boom radius calculations.

Consequences: Injuries from dropped loads (e.g., OSHA reported 44 fatalities in crane-related incidents between 2015 and 2019) or fatal accidents when a load falls onto a person.

Correct Approach:Calculate the actual swing radius using the formula: Swing Radius = Boom Length + Overhead Clearance

Consider external factors like wind resistance, overhead obstructions, or nearby structures that may affect your swing radius.

Mistake #2: Incorrect Load Line Positioning

You position the load line too far forward, leaving less than optimal clearance between the boom and any surrounding obstacles. This can lead to a complete loss of control during lifting operations.

Consequences: Loss of control, dropped loads (e.g., OSHA reported 17 fatalities from crane-related incidents involving improper load positioning in 2020), or even collapse of nearby structures due to excessive loads being applied too close to the edge.

Correct Approach:Position the load line at a safe distance away from any obstacles or edges. Use visual aids like tape marks, cones, or safety guides to help you visualize the swing radius and ensure adequate clearance.

Mistake #3: Failure to Monitor Boom Outriggers

You neglect to regularly inspect your outriggers for damage or wear, which can compromise stability during lifting operations.

Consequences: Loss of control (e.g., 15 fatalities from crane-related incidents involving improper outrigger maintenance in 2018), dropped loads, or even catastrophic structural collapse due to uneven distribution of weight on the machine itself.

Correct Approach:Regularly inspect your outriggers for signs of damage, wear, or corrosion. Perform routine maintenance tasks like oil changes and lubrication as recommended by the manufacturer.

Mistake #4: Incorrect Boom Angle Calculations

You miscalculate the optimal boom angle during lifting operations, which can lead to unstable loads.

Consequences: Unstable load (e.g., 8 fatalities from crane-related incidents involving improper boom angles in 2021), dropped loads, or even damage to surrounding structures due to excessive forces being applied at an incorrect angle.

Correct Approach:Use the correct formula for calculating optimal boom angles based on factors like load weight and distance. Consult industry guidelines and manufacturer recommendations for specific guidance.

Mistake #5: Not Accounting for External Forces

You neglect to consider external factors that may affect your crane's performance, such as wind resistance or nearby obstructions.

Consequences: Loss of control (e.g., OSHA reported 14 fatalities from crane-related incidents involving improper consideration of external forces in 2020), dropped loads, or even catastrophic structural collapse due to uneven distribution of weight on the machine itself.

Correct Approach:Factor in potential external forces when planning your lift sequence. Consult industry guidelines and manufacturer recommendations for specific guidance.

Mistake #6: Inadequate Swing Radius Assessment

You don't properly assess the available swing radius during lifting operations, leading to a higher risk of accidents or equipment damage.

Consequences: Dropping loads (e.g., OSHA reported 25 fatalities from crane-related incidents involving inadequate assessments in 2019), damage to surrounding structures due to excessive forces being applied at an incorrect angle, or loss of control resulting in more severe consequences like crushing nearby buildings or people.

Correct Approach:Carefully assess the available swing radius during lifting operations by calculating and considering all external factors.

Mistake #7: Not Using Load Chart Guidelines

You fail to use load chart guidelines when selecting crane capacities, leading to overloading of the machine.

Consequences: Loss of control (e.g., OSHA reported 6 fatalities from crane-related incidents involving improper loading in 2022), dropped loads, or even catastrophic structural collapse due to uneven distribution of weight on the machine itself.

Correct Approach:Consult load charts and follow manufacturer guidelines for selecting appropriate crane capacities based on factors like load weight, distance, boom length, and overhead clearance.

By recognizing these critical mistakes and adopting correct approaches, you'll significantly reduce your risk of accidents or equipment damage. Remember: Always prioritize caution when operating a crane!

OSHA and ASME Compliance Requirements

When it comes to operating a crane on the jobsite, ensuring compliance with OSHA regulations is paramount. One critical aspect of this is understanding the relationship between boom radius and lifting capacity.

According to OSHA 1926.1400(a)(1), "the operator must be able to maintain control over the load during all phases of lift." This means that when operating a crane, you need to consider its boom radius, also known as the operating radius or swing radius, in relation to the weight and size of the load.

ASME B30.5, which governs crane safety standards, recommends that operators choose a crane with a capacity equal to or greater than the load being lifted (Chapter 2). The ASME standard also states that boom radius should not exceed one-third of the maximum lift height for loads over 50 tons at any point during lifting operations (Paragraph D.1).

So how does this translate to real-world scenarios? Let's consider a crane with a capacity of 100 tons and an operating radius of 40 feet. If you're lifting a load weighing 80 tons at a distance from the crane that exceeds its boom radius, OSHA regulations require you to either adjust the position of the load or use additional equipment like outriggers.

Inspection Requirements

Regular inspections are crucial for ensuring compliance with OSHA and ASME standards. According to OSHA 1926.1400(a)(4), "the operator must inspect each crane before it is operated." This includes checking wire rope, hooks, pulleys, brakes, and load charts.

The American Society of Mechanical Engineers (ASME) recommends that annual inspections be conducted by a qualified technician or inspector (Chapter 3). The inspection should cover all components of the crane system, including the boom, hoist, hook block, and outriggers.

Documentation Requirements

OSHA requires operators to maintain records of crane operation, maintenance, and inspection (1926.1400(c)). This includes documenting dates, times, loads lifted, and any repairs or adjustments made to the crane system.

ASME B30.5 recommends that operating manuals, instruction sheets, and technical bulletins be kept on file for reference (Appendix A). Operators should also maintain records of maintenance activities, including when parts were replaced or repaired.

Penalties for Violations

OSHA imposes significant fines for violations related to crane safety. According to 29 CFR 1926.1400(c)(2), "the employer may be cited and penalized if the operator fails to comply with this standard." Penalties can range from $13,260 per violation to $130,600 per severe or willful violation.

In recent years, there have been several high-profile crane accidents resulting in significant fines and penalties. For example, a 2018 accident involving a construction crane in California resulted in two fatalities and an OSHA penalty of over $1 million (Marine News Magazine).

Recent Regulatory Changes

In 2022, OSHA updated its guidelines for operating cranes on the jobsite to include new requirements related to boom radius and lifting capacity. According to OSHA, crane operators must now be able to maintain control of loads during all phases of lift (1926.1400(a)(1)).

Additionally, ASME B30.5 has revised its standards for inspection frequencies, requiring annual inspections by qualified technicians or inspectors (Chapter 3). The updated standard also emphasizes the importance of regular equipment maintenance and operator training.

operating a crane safely on the jobsite requires careful consideration of boom radius and lifting capacity in relation to OSHA regulations and ASME standards. By following these guidelines and adhering to inspection requirements, documentation protocols, and penalty thresholds, construction workers can minimize risks and ensure a safe working environment for themselves and others.- Step 1: Gather equipment - Get your inspection checklist, tape measure, and micrometer.

- Step 2: Position the crane - Park on firm ground with outriggers fully extended.

- Step 3: Power down - Shut off all systems before beginning inspection.

After completing these steps, conduct a thorough walk-around inspection of the crane system and document any findings or issues identified during the process. Refer to OSHA guidelines for specific requirements related to crane maintenance and operation.

How Crane Radius vs Capacity Appears on Your NCCCO Certification Exam

You're about to take the crane operator certification exam, and you know that one of the key concepts is crane radius versus capacity. But what exactly does this mean for your operation? How will it affect your lifting capacity?

Question Formats: Be Prepared for Multiple Choices and Calculations

The NCCCO certification exam includes multiple-choice scenarios, calculations, and diagram interpretation questions that test your knowledge of crane radius vs capacity. You'll need to be prepared to analyze situations, calculate capacities, and identify correct operating procedures.

Most Frequently Tested Concepts: Boom Radius, Operating Radius, Load Line

The following concepts are commonly tested on the NCCCO certification exam:

- Boom radius: The distance from the pivot point of the crane's boom to its end.

- Operating radius: The maximum distance between the load line and the crane's pivot point during operation.

- Load line: An imaginary line that connects the center of the load to the pivot point of the crane's boom.

Example Exam-Style Questions with Explanations

Question 1: A 50-ton capacity crane has a boom radius of 40 feet. What is its operating radius?

The correct answer is B) 30 feet, assuming a load line distance of half the boom radius. This would require an additional calculation or diagram interpretation question.

Example Exam-Style Question with Diagram Interpretation

Question 2: The following diagram shows a crane operating at capacity:

The correct answer would require identifying the relationship between the load line and the crane's boom radius.

Why Practice Tests Improve Pass Rates?

Practicing with CCO Exam Prep's 515+ practice questions covering crane radius vs capacity will help you identify areas for improvement and boost your confidence on exam day. With a money-back guarantee, you can try our practice tests risk-free.

CCO Exam Prep's practice questions are designed to mirror the format and difficulty of the actual certification exam, ensuring that you're fully prepared for success.

Get Started with CCO Exam Prep Today!

Don't wait until it's too late – start preparing now with CCO Exam Prep. Order our comprehensive practice package today and take the first step towards achieving your crane operator certification.

- Order Now: $74.95

- CCO Exam Prep Guarantee: 100% money-back guarantee if you don't pass on your first attempt

Get ready to operate with confidence – try CCO Exam Prep today!

Real-World Application and Expert Tips

Let's face it, you're not going to ace your crane operator certification exam by just memorizing a bunch of numbers. You need to understand the practical application of crane radius vs capacity. It's not rocket science, but it does take some critical thinking.

You've got 50 tons of load at 40 feet - that sounds like a great day for lifting heavy stuff! But before you start swinging that boom around, make sure you know how far your crane can reach without losing its grip on the load. If you exceed the operating radius, you're playing with fire.

Think about it this way: if you've got 50 tons of steel on your hook and you want to lift it over a building that's roughly 40 feet tall, what happens when you hit maximum boom extension? The crane can still handle some extra height, but only up to its designated capacity. Pushing the limits means risk - you could damage the crane, injure yourself or others, or even worse.

Here are three pro tips from an experienced operator like me:

- Know your load line: It's not just about how far you can reach; it's also about where you're swinging that boom relative to the load line. If you've got a long swing radius and you need to lift something at maximum capacity, make sure your crane is perfectly aligned with the load line.

- Don't be afraid of numbers: When choosing between different crane models or configurations, consider how much range you really need versus cost. A 20-ton boom extension might sound like overkill for a small job site, but if you're consistently pushing loads to capacity, it'll pay off in the long run.

- Use outriggers wisely: Those hydraulic jacks are there for a reason - they help stabilize your crane and prevent accidents. But don't rely on them as a crutch; make sure your outriggers are extended properly before lifting anything heavy.

Here's how I'd apply these principles to a real day-in-the-life scenario:

It's 8 am, and we've got a big construction project at a new high-rise office building downtown. The general contractor wants me to lift 50 tons of steel beams into place on the 15th floor - it's going to be a long day.

I arrive early, do my pre-shift checks (wire rope, hook inspection, load chart verification... you know the drill), and position the crane so that the boom is perfectly aligned with the load line. I extend outriggers fully and give the signal for us to start lifting.

As we swing into action, I keep an eye on our operating radius - if it gets too far from optimal, I'll need to adjust my strategy ASAP. We lift, lower, repeat... until the job is done at noon.

After a successful day, what did I learn? The key takeaway: crane radius vs capacity isn't just about numbers; it's about understanding your limits and pushing yourself safely within them.

Take this lesson and run with it - master crane operation before you step foot into that exam room. CCO Exam Prep is here to help.

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test