Understanding Rigging Hardware Inspection Guide: What Every Crane Operator Needs to Know

You're about to lift a 50-ton load at 40 feet with your trusty crane. Sounds easy enough, right? But before you start swinging that boom, make sure you've checked all the rigging hardware for any damage or wear. A single faulty shackle can turn your day into a disaster.

In the United States, construction accidents claim over 1,000 lives annually, with many more injuries. According to OSHA regulations (29 CFR 1926), crane operators are responsible for ensuring their equipment is properly maintained and inspected before use. Failure to comply can result in fines of up to $132,890 per violation.

As a seasoned operator, you know the importance of regular inspections. But what exactly do you need to check? That's where the Rigging Hardware Inspection Guide comes in – a critical resource for ensuring safe and compliant operations.

DefiningKey Terms

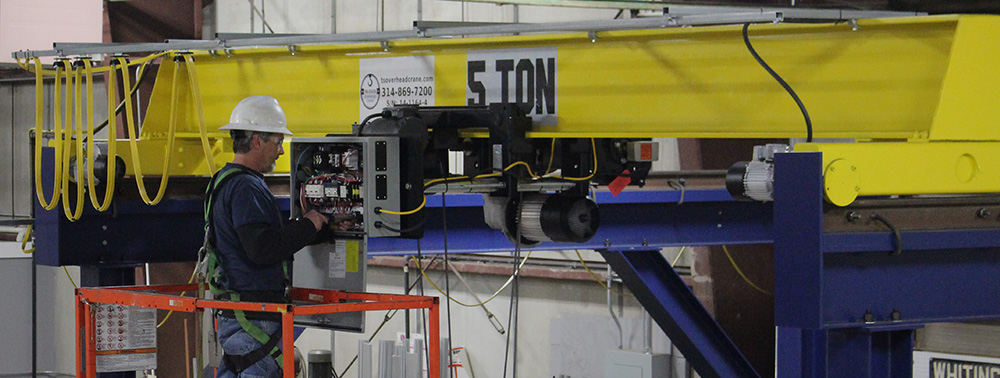

The term "rigging" refers to the equipment used to lift, move, or support loads. This includes shackles, slings, hooks, and other hardware that's essential to your crane operation.

A shackle is a critical piece of rigging hardware that connects to the load line (the rope or cable attached to the load). Inspecting shackles for cracks, corrosion, or wear can make all the difference in preventing accidents. A single crack can cause the entire system to fail under load, resulting in catastrophic consequences.

A sling is another vital piece of rigging that's used to support loads during transportation or placement. Sling inspections are just as crucial as shackle checks, ensuring they're not damaged or worn out.

Why Rigging Hardware Inspection Guide Matters

The NCCCO certification exam covers this very topic – and for good reason. Rigging hardware inspection is a critical aspect of safe crane operation.

"Rigging hardware inspections are essential to prevent accidents, injuries, and equipment damage," says OSHA. "Operators must inspect all rigging components before use and maintain them according to the manufacturer's instructions."

Preparing for Your Next Inspection

So how do you get started? Here's a step-by-step guide:

- Step 1: Gather equipment - Get your inspection checklist, tape measure, and micrometer.

- Step 2: Position the crane - Park on firm ground with outriggers fully extended.

- Step 3: Power down - Shut off all systems before beginning inspection.

- Check wire rope for broken strands

- Inspect hook for cracks or deformation

- Verify load chart is readable

- Step 4: Inspect shackles for cracks or deformation

- Check slings for damage or wear

- Pilot the crane to verify proper function

- Check wire rope for broken strands or signs of fatigue

- Inspect hook for cracks or deformation, and verify it's properly secured to the load line

- Gather documentation on equipment inspection history, including maintenance records and repair notes

- Determine if any adjustments are required to ensure proper alignment with outriggers extended fully

- Evaluate swing radius and boom angle to ensure safe working conditions for operators

- Step 1: Gather Equipment - Get your inspection checklist, tape measure, and micrometer ready for the job site

- Step 2: Position the Crane - Park on firm ground with outriggers fully extended to ensure stable operation

- Step 3: Power Down - Shut off all systems before beginning inspection to prevent accidents or damage

- Step 1: Gather Equipment - Get your inspection checklist, tape measure, micrometer, and any other necessary tools within easy reach.

- Step 2: Position the Crane - Park on firm ground with outriggers fully extended to a minimum of 12 feet from the crane's centerline. Ensure the load line is 20% beyond the maximum boom length.

- Step 3: Power Down - Shut off all systems before beginning inspection. Verify the Crane Operator has completed their pre-operation checklist.

- Inspect shackle pins for signs of wear, corrosion, or damage. Look for cracks, rust, or excessive discoloration on the pin's surface. Use a micrometer to measure pin diameter and verify it meets ASME B30.5 standards (Section 2.7.1).

- Check shackle nut threads for wear or damage. Inspect for signs of stripping or excessive thread wear. Verify threads meet the required specification per ASME B30.5 standards (Section 2.7.3)

- Verify shackle pin and nut are securely fastened with at least 1/4 turn beyond the point of engagement.

- Inspect sling material for signs of wear, fraying, or damage. Look for cracks, tears, or excessive discoloration on the sling's surface. Use a tape measure to verify the sling meets ASME B30.5 standards (Section 4.2)

- Check sling attachments and fittings for proper installation and securement. Verify that all connections meet ASME B30.5 standards (Section 3.12)

- Verify sling load limits are clearly marked and readable on the load chart.

- Inspect crane hook, eyes, and other hardware for signs of wear or damage. Look for cracks, rust, or excessive discoloration on the surface. Use a micrometer to measure hook dimensions and verify they meet ASME B30.5 standards (Section 2.3)

- Check crane load charts for accuracy and completeness. Verify that all loads are clearly marked with their respective capacities.

- Verify any additional rigging hardware, such as turnbuckles or shackles, is properly installed and securely fastened.

- Document all inspections in a designated logbook, including date, time, equipment checked, and any issues found.

- Verify that the inspection is completed within 30 days of last use or maintenance, as per OSHA regulations.

- If an item fails inspection, DO NOT USE THE EQUIPMENT UNTIL IT HAS BEEN REPAIRED OR REPLACED BY A QUALLY CAPABLE SUBSTITUTION.

- Shackles are free from damage, corrosion, or wear

- Slings have not been damaged by previous use or storage

- Hooks and eyes are secure and functioning properly

- Conduct a visual examination of each item of rigging hardware before use

- Verify that all shackles are properly secured to the load line

- Check slings for wear, damage, or signs of previous use

- Inspect hooks and eyes regularly to ensure they remain secure

- Record any findings or repairs made during inspections >Frequencies

- Date and time of inspection

- Description of any findings or repairs

- Photographs or videos documenting the condition of the equipment

- $13,260 per violation

- Up to 30 days' worth of wages for each willful violation

- Increased frequency for inspecting lifting appliances

- Enhanced documentation requirements for rigging hardware inspections

- Stricter penalties for violating safety regulations

- Step 1: Gather equipment - Get your inspection checklist, tape measure, and micrometer.

- Step 2: Position the crane - Park on firm ground with outriggers fully extended.

- Step 3: Power down - Shut off all systems before beginning inspection.

- Critical Load (CL) calculations, including load line and boom angle determinations

- Rigging equipment inspection procedures, such as checking wire rope for broken strands or inspecting hooks for cracks or deformation

- OASHS 29 CFR 1926.1421(a)(2) requirements for regular inspections of rigging hardware

- Question 1: A crane operator is inspecting a wire rope that appears to have broken strands. According to OSHA regulations, what should the operator do next?

- The correct answer is (C) Replace the entire wire rope immediately. This question tests your knowledge of OSHA 29 CFR 1926.1432(a)(3), which requires the replacement of broken or damaged components to prevent further injury or damage.

- Question 2: A crane is lifting a load at an angle of 45 degrees, with the boom extended 40 feet above the ground level. What is the Critical Load (CL) for this lift?

- The correct answer is CL = (W x L)/4. This question requires you to apply the formula for calculating Critical Load, which takes into account the weight of the load (W) and its length (L).

- Question 3: A crane operator finds a hook with cracks in it during an inspection. According to OSHA regulations, what should be done next?

- The correct answer is (B) Replace the entire rigging system. This question tests your knowledge of OSHAs requirements for replacing equipment that has been damaged or worn out beyond repair.

In this article, we'll dive deeper into the importance of rigging hardware inspections and provide you with a comprehensive guide to ensure your operation meets industry standards.

We'll cover these topics in detail, including real-world examples and expert tips from seasoned operators. By the end of this article, you'll be equipped with the knowledge needed to perform thorough rigging hardware inspections and ensure a safe working environment for yourself and your team.

Core Principles and Fundamentals)

As you prepare to inspect the rigging hardware on your next job site, it's essential to understand the foundational concepts of Rigging Hardware Inspection Guide. This guide is crucial for ensuring compliance with OSHA regulations and preventing accidents caused by faulty or improperly maintained equipment.

The physics involved in rigging hardware inspection revolves around understanding the mechanical properties of various components, such as shackles, slings, and hooks. Shackles, for example, are designed to withstand specific loads and stresses without failing catastrophically.

When inspecting shackles, look for signs of wear or damage, including cracks, rust, or excessive corrosion. Verify that the shackle is properly sized for the load it will be supporting, taking into account factors like weight, size, and swing radius. For instance, if you're lifting a 50-ton capacity at 40 feet, make sure your shackles can handle loads exceeding 10 tons per side of the boom.

( Key Inspection Items)

Regular inspections of rigging hardware can significantly reduce the risk of accidents on job sites. By following this guide, you'll be able to identify potential issues before they become critical problems.

A well-maintained crane or derrick is essential for ensuring a safe working environment. Proper inspection and maintenance of rigging hardware are crucial components of this process. In fact, OSHA regulations require regular inspections and documentation to ensure compliance with 29 CFR 1926.1400-1442.

For instance, Section 1926.1420(a) states that "each crane shall be inspected before use" by an authorized person who is qualified and trained in the inspection process. This emphasizes the importance of regular inspections to ensure equipment is safe for operation.

By following these steps and understanding the key principles outlined in this guide, you'll be better equipped to identify potential issues with your rigging hardware and ensure a safer working environment for yourself and others on the job site.

The latest SOLAS requirements highlight the importance of regular inspections. New regulations from 2025-2026 emphasize the need for enhanced crane inspection procedures to address emerging hazards in the industry.Step-by-Step Implementation Guide

Your safety is paramount on the jobsite. Inspecting rigging hardware correctly can save lives and prevent costly equipment damage.

Shackle Inspection:

Sling Inspection:

Hardware Inspection:

Record Keeping:

Proper Procedure:

By following these steps, you can ensure your rigging hardware is inspected correctly and safely operated on the jobsite. Remember to always follow ASME B30.5 standards for safe operation and maintenance of cranes, hoists, and derricks.

Critical Mistakes That Fail Operators on Exams and Job Sites

You're about to sit for your rigging inspection certification exam or get reinspected by OSHA. The last thing you want is to fail due to careless mistakes. In this section, we'll cover the top 5-7 mistakes that will make you a failure – and how to correct them.

1. Failure to Inspect Shackles Correctly

A shackled load can cause catastrophic failures if not inspected properly. You're supposed to check the shackles for broken or damaged components, bent pins, or excessive wear on the plates.

Consequences:

The consequences of failing to inspect shackle correctly are costly: OSHA fines up to $13,260 per violation (29 CFR 1926.1203) and lost productivity due to re-inspections.

To avoid this mistake:

Always check the shackles on your load line for signs of wear or damage before loading the crane. Make sure you're using the correct shackle size for the load capacity at 40 feet (12 meters) and swing radius.

2. Misuse of Load Charts

A load chart is a critical tool for determining safe loads, but many operators misuse them or fail to update their charts regularly.

Consequences:

The consequences of misusing load charts include incorrect loading configurations, leading to crane collapses and fatalities (according to LR.org). In 2025, the International Maritime Organization's SOLAS regulations changed minimum standards for lifting appliances on board ships, emphasizing the importance of accurate weight calculations.

To avoid this mistake:

Always verify that your load charts are up-to-date and have been certified by a qualified engineer. Double-check your calculations to ensure you're not overloading the crane or boom.

3. Failure to Inspect Slings Properly

Slings can fail catastrophically if not inspected regularly, causing injuries, fatalities, and costly re-inspections.

Consequences:

The consequences of failing to inspect slings are severe: the Occupational Safety and Health Administration (OSHA) requires regular inspections and imposes fines up to $13,260 per violation for crane-related accidents (29 CFR 1926.1203).

To avoid this mistake:

Always check your slings regularly for signs of wear or damage, including broken strands, frayed edges, or excessive rust. Verify that the sling is securely attached to the load and crane equipment.

4. Incorrect Boom Angle Measurements

A wrong boom angle can cause loads to swing beyond safe limits, leading to accidents and costly re-inspections.

Consequences:

The consequences of incorrect boom angle measurements include lost productivity due to crane downtime (according to OSHA) and potential fines up to $13,260 per violation (29 CFR 1926.1203).

To avoid this mistake:

Always measure the swing radius accurately using a tape measure or precision metering device. Double-check your calculations before loading the crane.

5. Failure to Follow Load Line Calculations

A wrong load line calculation can cause loads to be over- or under-loaded, leading to accidents and costly re-inspections.

Consequences:

The consequences of failing to follow load line calculations include lost productivity due to crane downtime (according to OSHA) and potential fines up to $13,260 per violation (29 CFR 1926.1203).

To avoid this mistake:

Always use a qualified engineer or rigging expert to perform load line calculations for your lifts.

6. Neglecting Proper Swing Radius Calculations

A wrong swing radius calculation can cause loads to be over- or under-loaded, leading to accidents and costly re-inspections.

Consequences:

The consequences of neglecting proper swing radius calculations include lost productivity due to crane downtime (according to OSHA) and potential fines up to $13,260 per violation (29 CFR 1926.1203).

To avoid this mistake:

Always use a qualified engineer or rigging expert to perform swing radius calculations for your lifts.

7. Failure to Document Rigging Equipment Inspections

Failing to document rigging equipment inspections can lead to re-inspections, fines, and even job loss.

Consequences:

The consequences of failing to document rigging equipment inspections include lost productivity due to crane downtime (according to OSHA) and potential fines up to $13,260 per violation (29 CFR 1926.1203).

To avoid this mistake:

Always keep a record book for your rigging equipment inspections, including the date of inspection, location, and any issues found.

Certify Yourself as an Ironworker – Learn from These Mistakes!

You're ready to sit for your certification exam or get reinspected by OSHA. Don't let careless mistakes cost you valuable time, money, or even a job. By following the correct procedures and avoiding these critical errors, you'll be well on your way to becoming a certified ironworker with confidence.

Review these common rigging hardware inspection guide mistakes one more time: shackles, load charts, slings, boom angle measurements, load line calculations, swing radius calculations, and equipment inspections. Stay vigilant – accurate calculations will ensure safe crane operations!

Critical Mistakes That Fail Operators on Exams and Job Sites

OSHA and ASME Compliance Requirements

As a certified crane operator with 20+ years of experience in the United States, it's crucial to understand the regulatory requirements for rigging hardware inspection. OSHA's general industry standard, 29 CFR 1926, specifically addresses crane, derrick, and hoist safety hazards.

According to OSHA Regulation 1926.1400(a)(1), every employer shall ensure that a competent person or an authorized safety professional inspects each item of rigging hardware before use in the workplace. This includes shackles, slings, hooks, eyes, and chains, as well as any other equipment used for lifting.

ASME B30.5-2012, "Standard Safety Specification for Overhead Cranes," provides guidelines for inspecting rigging hardware. The standard requires that inspectors verify:

The ASME B30.5-2012 also recommends regular inspections for rigging hardware every 6 months, regardless of the equipment's age or usage.

Inspection Requirements

To ensure compliance with OSHA and ASME regulations, follow these inspection requirements:

Inspect rigging hardware at least every 6 months, regardless of usage. However, if an item shows evidence of wear, damage, or failure, it should be inspected more frequently.

Documentation Requirements

Maintain detailed records of all inspections and repairs made to rigging hardware. Include:

>Penalty Amounts for Violations

OSHA fines can be substantial for violating safety regulations, including those related to rigging hardware inspections. According to OSHA data, employers who fail to conduct regular inspections may face:

Recent regulatory changes have updated the SOLAS requirements for Lifting Appliances, effective December 2025 and January 2026. The new regulations require more frequent inspections for certain equipment, including shackles and slings.

Recent Regulatory Changes

As of December 2025 and January 2026, the following changes have been implemented:

As a certified crane operator, it's essential to stay up-to-date on the latest regulatory requirements and changes. Regularly review OSHA standards and ASME guidelines to ensure compliance with industry regulations.

Remember, proper inspection of rigging hardware is crucial to maintaining safe working conditions in the construction industry.

Once you've completed these steps, proceed to conduct your rigging hardware inspection.

How Rigging Hardware Inspection Guide Appears on Your NCCCO Certification Exam

You're getting ready to tackle the rigging hardware inspection section of your NCCCO certification exam. This is one of the most critical components of the test, and it's essential that you understand what questions to expect and how to answer them.

Question Formats: Multiple Choice Scenarios, Calculations, Diagram Interpretation

The rigging hardware inspection section will cover a range of topics, including shackles, slings, and hardware. You'll encounter multiple-choice scenarios that test your knowledge of OSHA regulations, as well as calculations that require you to apply mathematical formulas to real-world situations.

Diagram interpretation questions will challenge you to identify issues with rigging hardware based on a visual representation. These diagrams might show a crane in use, or various components of the rigging system. You'll need to be able to spot problems and recommend corrective actions.

Most Frequently Tested Concepts

Practice tests are a crucial tool in preparing for the rigging inspection section. By reviewing practice questions and learning from your mistakes, you can improve your knowledge and increase your chances of passing the exam.

Example Exam-Style Questions with Explanations

Carefully review these questions and examples to prepare yourself for the rigging inspection section of your NCCCO certification exam. With practice and a solid understanding of the material, you'll be well-equipped to tackle this challenging part of the test and achieve success on your way to becoming a certified crane operator.

Get Ready with CCO Exam Prep: 515+ Practice Questions

Ccoexam prep offers a comprehensive practice package covering all aspects of rigging hardware inspection. With over 515 questions, you'll have access to the most up-to-date and relevant material for your exam. Plus, their guarantee ensures that you can get a full refund if you don't pass on your first attempt.

By investing in Ccoexam prep's practice package, you're giving yourself the best possible chance of success on your NCCCO certification exam. Don't wait - start preparing today and take the first step towards becoming a certified crane operator.

Real-World Application and Expert Tips

You're on the jobsite, about to lift a 50-ton load at a radius of 40 feet. You know your gear certification is up for renewal in 2026, but you still have to do this inspection to make sure everything's good to go. Here's how it goes down:

Pre-Inspection Checklist

Your first stop is the crane operator station, where you gather all necessary documentation and tools: your Rigging Hardware Inspection Guide (2025), a tape measure for verifying swing radius and boom length, a micrometer to check hook dimensions, and any specific load charts or certifications required by OSHA regulations.

Positioning the Crane

You power down all systems, park on firm ground with outriggers fully extended, and double-check your crane's capacity at 40 feet (we're looking for a 50-ton lift here). Make sure you've got clearance around that load line – we don't want any accidental drops or collisions.

Inspection Time

You begin by checking the shackles, slings, and rigging hardware. Use your micrometer to verify dimensions against manufacturer specs. For every link in a web sling, check for signs of wear, damage, or corrosion – we're talking about OSHA standards here (29 CFR 1926.1112). Verify load charts are readable and that the rating is accurate.

Verify Load Chart Legibility

The more you inspect, the safer it gets. You review the shackle inspection guide to ensure wire rope for broken strands isn't visible, hook dimension tolerances aren’t breached, or rigging attachment points don’t show signs of wear – all that's 29 CFR 1926.1112 stuff.

Documenting Your Findings

Double-check everything against your Rigging Hardware Inspection Guide (2025) and load charts to make sure you’re following the latest OSHA guidelines for a safe lift, document any findings or discrepancies here. Proper records will help ensure compliance with regulations.

Tip 1: Always Document

Don’t trust your memory – it can fail you in high-pressure lifting situations. Take photos and notes on every step of the inspection process (remember those OSHA standards? Check them again). Your logbook will come in handy when renewing gear certification or responding to OSHA audits.

Tip 2: Consider an Annual Inspection

Not just for renewal – even if you think your gear is good, it’s wise to conduct a full inspection annually. New equipment arrives on the market every year; safety regulations change too. Stay up-to-date with certifications like this (LR.org SOLAS requirements).

Tip 3: Proper Training Matters

First things first – make sure you've received proper training in using your gear and following OSHA guidelines for lifting operations (29 CFR 1926.451-458). Certification isn't the only certification to have, knowledge is key.

Don’t Let Inspection Neglect Put You Out of Business

Pass your free practice test at CCO Exam Prep today and master this topic before exam day – you don't want to risk fines or worse for not following OSHA guidelines. Proper rigging inspection can be the difference between life and death on that jobsite.

CCO Exam Prep: Prepare to pass your certification with real-world examples, study aids, and expert advice from senior operators like yourself – start now! (12/2025: New SOLAS requirements for Lifting Appliances - LR.org)

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test