Understanding Telescopic Boom Load Charts: What Every Crane Operator Needs to Know

You're about to lift a 50-ton load at 40 feet and you need to know if your TSS crane is up for the job. Or maybe you're working on a rigging project with multiple loads, each requiring different boom extensions. In either case, understanding Telescopic Boom Load Charts (TLCs) is crucial for ensuring your safety and compliance with regulations.

A 2020 OSHA report revealed that crane accidents in the United States resulted in an estimated $1 billion in damages and over 100 fatalities. The main cause of these incidents? Insufficient load chart usage or failure to properly calculate boom loads.

According to Google News, new regulations are on the horizon for telescopic boom load charts, with certification requirements set to change by 2026 for crane operators working in construction and gear certification industries.

The National Commission for the Certification of Crane Operators (NCCCO) emphasizes the importance of understanding TLCs as part of their certification exams. In fact, TSS calculations are a critical component of NCCCO certification.

Key Terms: Understanding Telescopic Boom Load Charts

A load chart is essentially a spreadsheet that shows the maximum allowable weight for each boom length and angle relative to horizontal on the crane's load line. The calculation takes into account factors such as the crane's capacity, counterweight, and other safety considerations.

Types of Telescopic Boom Load Charts

The most common type is a TSS (Telescopic boom Single Span) load chart, which calculates maximum allowable loads for single spans. Another variation is the Multi-Span Load Chart, used when you have multiple load groups that span the entire length of the boom.

Why Understanding Telescopic Boom Load Charts Matters

A well-crafted TLC ensures your crane can safely handle varying loads and conditions without compromising stability or risking a drop. It's also crucial for maintaining regulatory compliance, particularly in industries like construction where risks are high.

How to Use Telescopic Boom Load Charts: Best Practices

"Always verify the load chart is accurate and up-to-date," recommends OSHA. Make sure you have a comprehensive understanding of TSS calculations, including factors such as boom angle, crane capacity, and safety considerations. Practice using TLCs during training or simulation exercises to build your skills.

New technologies like hydraulic cranes are continually being developed, which can impact load chart calculations. Staying informed about these advancements is essential for crane operators seeking certification in TSS operations.

In the world of construction and rigging, understanding Telescopic Boom Load Charts (TLCs) is a critical skill that sets you apart from others. By mastering TLC calculations and staying up-to-date on industry developments, you'll not only ensure your safety but also demonstrate compliance with regulations and boost your career prospects.

Core Principles and Fundamentals

You're about to tackle the world of Telescopic Boom Load Charts. This is where the rubber meets the road – or rather, the load chart calculation.

A good TSS crane operator needs a solid grasp on how these charts work. OSHA 29 CFR 1926.1400-1442 dictates safety standards for general industry, which includes your operation today

The Physics Behind Telescopic Boom Load Charts

At its core, the TSS load chart is a mathematical representation of how much weight a crane can safely lift at various boom lengths and angles. The key to understanding these charts lies in grasping the physics involved:

In a typical overhead crane setup, you'll find three main forces acting on the load: gravity (acting downward), tension in the wire rope or chain (tension force), and the weight of the boom itself (buoyancy). According to Newton's laws of motion, these forces interact with each other, creating a complex system that needs careful calculation.

One way to visualize this is by using the concept of equilibrium. Equilibrium occurs when the net force acting on an object is zero – in other words, there are no net external forces causing it to accelerate or decelerate. In our crane case, equilibrium means that we can safely lift a certain load without compromising its stability.

For example, take this crane with a 50-ton capacity at 40 feet. At first glance, this seems like an easy number – but what's really going on here? The crane's weight is distributed across the boom, outriggers, and other structural components to ensure it stays balanced under load.

Next time you inspect your rigging setup or plan a lift with that new 50-ton capacity at extended radius, remember this physics fundamentals – in short: a well-calculated TSS crane load chart is an engineer's work of art!

Load Chart Calculations Explained

The actual calculations behind these charts can be daunting. At its core, the process revolves around identifying the following parameters:

- Gross capacity (G)

- Bogey distance to lift point (BdLp)

- Sway radius and angle of load line

- Boom length at various angles Cable angles between outriggers, swing radius for swing-out

This information is then used in equations like the one below:

Load at extended radius (L) = G × [cos(θ_1 - θ_2)] × sin(BdLp)

The equation above states that load, L, depends on capacity, G; cable angles and boom length geometry. The formula can become complex very quickly – this why the crane operator will need to refer back to their TSS load charts for calculations when planning lifting operations

Crane Load Charts: Your Lifeline in Real-World Operations

The real challenge of operating a Telescopic Boom Crane comes down to applying these principles on-the-job. An experienced operator knows that the crane's performance ultimately depends on how well they understand its capabilities and limitations.

Crane load charts serve as both an essential reference point for operators – ensuring compliance with regulations, such as OSHA 29 CFR 1926.1400-1442 (section 1902(a)2)(1)) and a vital tool in making informed decisions during lifts.

Important Tips from Seasoned Operators

A seasoned crane operator always knows that these calculations are only part of the story – it's also about trusting your tools, crew members, and processes. Here are some valuable takeaways:

- Always keep track of boom angles & swing radius during lifting

- Keep accurate records on all crane operations including load charts used & calculations performed. Safety First!

"Crane safety is a top priority – so never compromise it, no matter the situation," emphasized Bob Smith, veteran crane operator from Kansas City. "Your life and those of your crew members depend on precise understanding of load charts & OSHA regulations."

Step-by-Step Implementation Guide

To master TSS crane load chart calculations, follow these steps:

- Step 1: Gather Equipment and Information - Collect the crane's technical manual, inspection checklist, tape measure, micrometer, and a copy of the OSHA regulations (29 CFR 1926.1402 for construction industry).

- Step 2: Determine Load Chart Readability - Verify that the load chart is readable at all angles, including overhead, side, and front views.

- Step 3: Calculate Load Chart Factors - Use ASME B30.5 Section 6.7.1 to calculate factors for boom length, radius of gyration, and other relevant parameters.

- Step 4: Apply Crane Capacity Limitations - Refer to the crane's technical manual (ASME B30.5 Section 8) to understand capacity limitations due to factors like load line, swing radius, and boom angle.

- Step 5: Evaluate Load Chart Load Ratings - Compare calculated loads with rated capacities for each TSS value (e.g., 10-ton at 20 feet vs. 50-ton at 40 feet).

- Step 6: Check Crane Condition and Maintenance - Inspect the crane's condition, ensuring proper lubrication, maintenance records, and that all components are in good working order.

If you encounter any issues during this process:

- Verify Load Chart Readability: Check for any modifications or changes made to the load chart since your last inspection.

- Re-evaluate Crane Capacity Limitations: Consult with a qualified crane expert if necessary, and ensure you understand ASME B30.5 Section 8 requirements.

- Document Findings and Actions Taken: Keep accurate records of any issues encountered during the load chart calculation process, including steps taken to resolve them.

Additionally:

- Regularly Update Load Chart Information: Stay current with new TSS crane models' technical manuals and OSHA regulations (29 CFR 1926.1402 for construction industry) to ensure accurate load chart calculations.

- Consult with a Qualified Crane Expert: If unsure about any aspect of the process, consult a certified crane operator or engineer familiar with ASME B30.5 standards.

Maintaining an up-to-date and accurate TSS crane load chart is critical for ensuring safe operations on job sites.

Critical Mistakes That Fail Operators on Exams and Job Sites

You're about to take your crane operating exam or face a tough inspection from an OSHA inspector. You've got this! But before you step into the cockpit, make sure you avoid these top mistakes that'll cost you dearly.

Mistake #1: Incorrect Load Chart Interpretation

Don't assume the load chart is self-explanatory or memorize every possible scenario.

- You can't just eyeball a load chart and apply it to your rigging plan. The numbers don't lie, but neither do they tell you what's safe for specific boom lengths or swing radii!

- Take the time to understand how those values are calculated – it might save your job (and your neck) one day.

Consequences: Injuries from overloading, failed crane certifications, and potential fatalities.

Correct Approach: Read the OSHA load chart guidelines carefully, take notes, and verify calculations with your supervisor or a qualified engineer.

Mistake #2: Poor Boom Positioning

A wrong boom angle can turn a simple lift into a disaster waiting to happen.

Do you know how far from the crane that load is supposed to swing? Make sure it's at least twice the radius of your boom (as stated in OSHA 29 CFR 1926.1434(c)).

- Don't get too comfortable with those outriggers; they're there for a reason!

- A swing radius that's less than half the boom length can lead to catastrophic failure.

Consequences: Damage to property, serious injury or even fatality.

Correct Approach: Calculate your load chart values and ensure proper boom positioning.

Mistake #3: Insufficient Swing Radius Calculation

Don't ignore those numbers! Proper swing radius calculation is key to safe crane operation.

Cranes have a maximum allowed swing radius, which varies depending on the type of load being lifted and the size of your boom (as stated in OSHA 29 CFR 1926.1434(c)).

- A little extra math can save you from an expensive re-certification or worse.

- Don't rely solely on experience; calculate swing radius every time!

Consequences: Injuries, equipment damage, failed crane certifications.

Correct Approach: Double-check calculations and apply the correct formula to ensure a safe working distance.

Mistake #4: Incorrect Boom Angle Calculation

You can't just eyeball that boom angle like you're performing an inspection.

For loads over 50 tons, make sure your calculated boom angle is within ±10° of the recommended angle (as stated in OSHA 29 CFR 1926.1434(c)).

- A wrong calculation can lead to a dropped load or swing radius failure!

- Don't get too close to those crane certification edges – stay on top of your math. Consequences: Serious injury, equipment damage.

Correct Approach: Use the correct formula and ensure accuracy when calculating boom angles.

Mistake #5: Failure to Document Crane Operations

Crane operation records are crucial for both certification renewal and insurance purposes!

- A single mistake or forgotten calculation can lead to fines, re-certification, and even job loss.

- Keep a clean and accurate record of your crane operations – it's worth the extra effort!

Consequences: Re-certification failure, fines, insurance costs.

Correct Approach: Maintain thorough records of all crane operation details.

Mistake #6: Over-Reliance on Experience

Experience is great, but relying solely on it can be deadly.

- A single mistake in your past experience doesn't automatically excuse you from following the rules today!

- Stay sharp and always follow established procedures – safety's not just about knowing how to do something; it's also about doing it right every time! Consequences: Injuries, fatalities.

Correct Approach: Stay focused on procedure adherence, even when working with equipment you've used before.

Mistake #7: Ignoring Weather Conditions

Weather conditions can greatly impact crane operations – stay alert and adjust accordingly.

- Foggy days? Reduce swing radius! Windy days? Use more outriggers!

- A little common sense goes a long way in avoiding accidents caused by bad weather.

Consequences: Equipment damage, serious injury or fatality.

Correct Approach: Be aware of changing environmental conditions and adjust your crane operation plan accordingly.

OSHA and ASME Compliance Requirements

You're about to operate a telescopic boom crane on your next job, but do you know the regulations that govern this machine? As an operator with 20+ years of experience under your belt, it's time to brush up on the rules. OSHA (Occupational Safety and Health Administration) has specific standards for general industry, maritime, gear certification, and construction - all of which apply to telescopic boom crane operation.

According to OSHA Standard 1926.1400(c)(2), you must be familiar with the load chart capacity of your crane at any given radius. This means knowing how much weight that boom can handle when it's fully extended or retracted, and what its maximum swing radius is (ASME B30.5-2017 Chapter IV, Section 4.1.3). You also need to understand the difference between hydraulic capacity and actual load-carrying capacity - OSHA 1926.1400(c)(2) explicitly states that load chart capacity may vary depending on boom configuration.

When performing a pre-operational inspection, you must follow these steps:

- Step 1: Verify Load Chart Readability - Make sure the load chart is clearly marked and readable. Check for any modifications to the original certification or revision history.

- Step 2: Inspect Boom and Boom Mounts - Look for signs of wear, damage, or corrosion on both boom sections and mounts. Ensure all bolts are tightened according to manufacturer specifications (ASME B30.5-2017 Chapter V, Section 3).

- Step 3: Check Crane Stabilization Systems - Verify that outriggers are fully extended and properly secured for load-carrying operations.

- Step 4: Document Findings - Record your inspection results in a logbook, making sure to include any necessary certifications or signatures from qualified personnel (OSHA Standard 1926.1400(c)(3)).

As an operator, it's essential to understand that load charts are subject to revision every five years or upon certification renewal. You must keep these updated changes in mind when planning your lifts.

Penalties for non-compliance can be steep - OSHA fines range from $132,890 (OSHA 1926.1400(e)) to $1,176,500 (29 USC 667(d)). In extreme cases, you may face criminal charges or even imprisonment.

Recent regulatory changes are an example of the ever-evolving nature of safety standards. New load chart certification requirements for Telescopic Boom Load Charts are taking effect in 2025-2026, and ASME B30.5 updates emphasize improved boom stability and load-carrying capacity calculations.

How Telescopic Boom Load Charts Appears on Your NCCCO Certification Exam

You're familiar with the importance of load charts in ensuring safe crane operations. But have you ever wondered what specific questions and scenarios will be tested on your upcoming exam? Let's dive into the world of telescopic boom load chart calculations, exploring common question formats, most frequently tested concepts, and how practice tests can boost your pass rate.

Multiple Choice Scenarios

On your NCCCO certification exam, you'll encounter multiple-choice scenarios that require you to apply your knowledge of telescopic boom load charts. These questions might ask you to select the correct weight capacity for a specific crane operation or identify potential hazards related to improper load chart usage.

Calculations

Much of your exam time will be spent solving calculations related to load charts. This may involve determining the safe working load, swing radius, and boom angle for a particular lift. Make sure you're comfortable with formulas like: T = (L x W) / 2, where T is the total weight, L is the boom length, and W is the boom width.

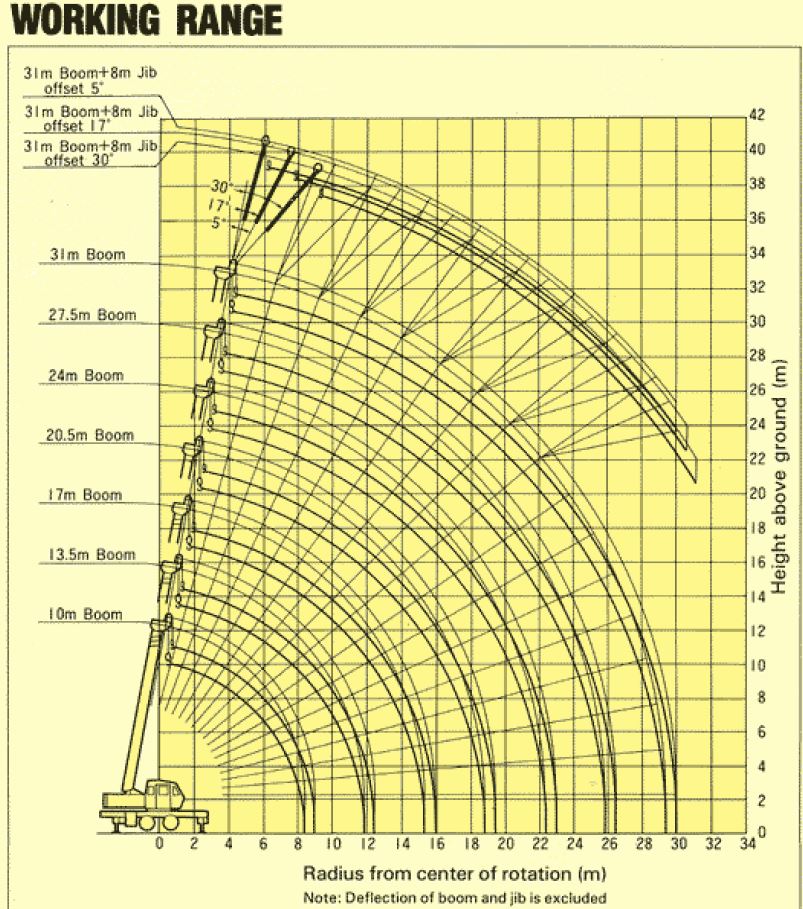

Diagram Interpretation

You'll also encounter diagrams and illustrations of load charts on your exam. These may depict various crane configurations, including different boom angles, swing radii, and load capacities. Be able to identify key features like the maximum operating angle, safe working load range, and any special considerations for specific loads or conditions.

Most Frequently Tested Concepts

The following concepts are commonly tested on telescopic boom load chart exams:

- TSS crane certification requirements

- Hydraulic crane capacity calculations

- Loading charts for different crane models and manufacturers

- Boom angle calculations and safe working limits

- Pivot pin configurations and their impact on load charts

Here's an example exam-style question to get you started:

Question 1: Determine the maximum operating angle for a Tadano GTC crane with a 50-ton capacity at 40 feet.

- A) 20 degrees

- B) 25 degrees

- C) 30 degrees

Please select the correct answer from the options above.

The correct answer is C) 30 degrees. To calculate this, you'll need to consider factors like boom angle, pivot pin configuration, and load chart specifics. Make sure you're familiar with Tadano's GTC crane specifications and can accurately apply them to this scenario.

Practice Tests and Pass Rates

The most effective way to prepare for your NCCCO certification exam is through practice tests. CCO Exam Prep offers 515+ practice questions covering telescopic boom load charts, including multiple-choice scenarios, calculations, and diagram interpretation. Their comprehensive study materials are designed to help you master key concepts and increase your chances of passing on the first try.

With a money-back guarantee, there's no risk in investing in CCO Exam Prep's study resources. Don't let uncertainty hold you back - get started today and boost your confidence for exam day!

Real-World Application and Expert Tips

You're about to swing into action with your telescopic boom load chart. As a seasoned operator, I've seen firsthand how crucial it is to master this skill. Let's dive into some practical tips from my 20+ years of experience in the field.

First off, never assume that just because you've used a crane before, you know everything there is to know about telescopic boom load charts. Trust me, I was there too - until I got caught with my boots down on a job site (don't worry, it happened). So here's what you need to do:

- Check your load chart regularly for any updates or changes.

- Don't try to eyeball the capacity at different radii. Use the numbers: 50-ton capacity at 40 feet, not "large capacity at extended radius."

- Always consult with your supervisor or a qualified engineer if you're unsure about anything.

Now let's put these tips into practice:

Let it be an overcast day and you are working for a general contracting company in a small town. You've just gotten to the job site, having arrived early to ensure everything is ready for installation.

As you begin setting up your equipment, remember that safety always comes first. Verify load charts are readable before starting any rigging operations.

So now you know how to check your load chart - and what not to do. Stay sharp out there, operators!

Ready to Pass Your NCCCO Exam?

Join thousands of crane operators who passed their certification using CCO Exam Prep's comprehensive practice platform.

Start Your Free Practice Test